Boiling disinfection is a commonly used sterilization method for food packaging. Generally, boiling at 100 ℃ for 30 minutes is used to kill the propagules of bacteria and achieve a better disinfection effect. However, the boiling process also poses a challenge to the composite effect of the packaging bag. Solvent-free composite glue plays a very important role as the “core member” of packaging composite.

Wanhua Chemical adheres to green innovative materials as the engine, and launches solvent-free boiled universal glue WANNATE® 6048A / WANEXEL® 748B, applicable to various composite structures, provides another environmental protection choice for the flexible packaging industry.

WANNATE® 6048A /WANEXEL® 748B Boiled Universal Glue

1. Wide adaptability and high aesthetics

The product has excellent compatibility with inks, and has high compatibility with various film materials, and can cover a variety of composite structures; the composite effect is high in transparency, providing a powerful solution for the decorative and aesthetic requirements of packaging bags. support.

2. No peculiar smell, meeting the needs of high odor sensitivity

No peculiar smell, meeting the needs of application scenarios with high odor sensitivity, such as pet food packaging such as cat and dog food, and product packaging in the pharmaceutical industry.

3. Excellent process performance

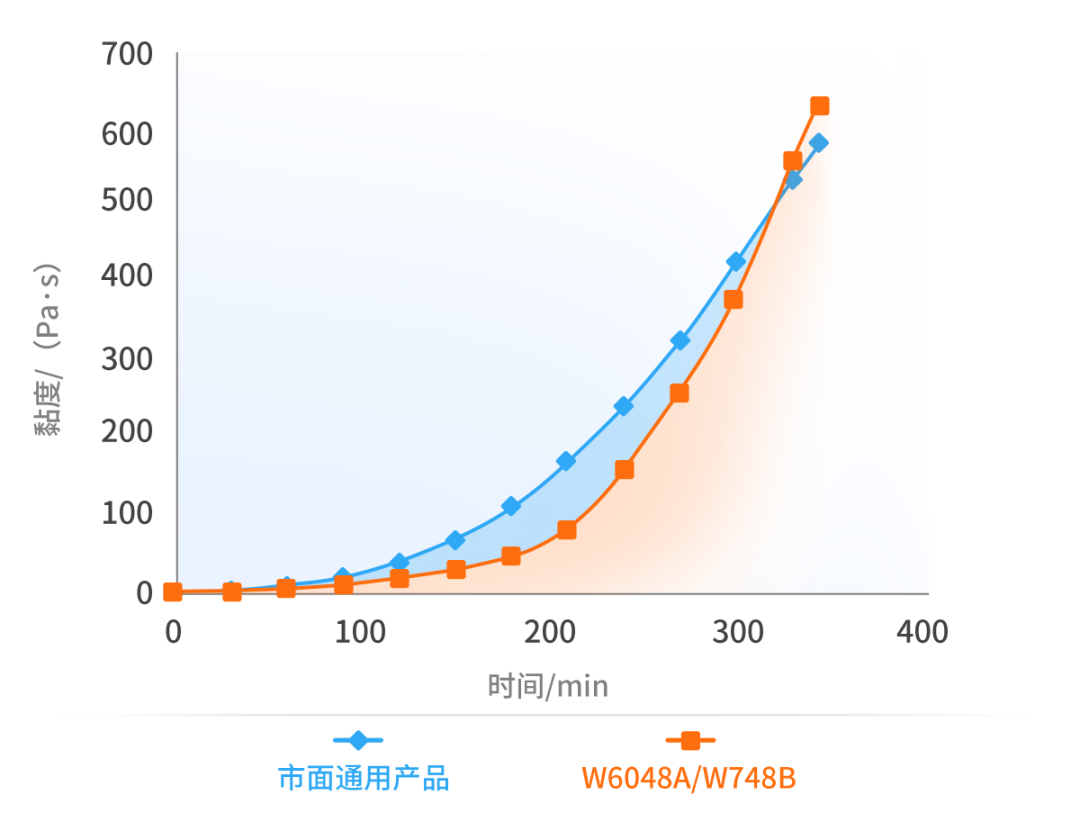

The glue tank has a long opening period, and the viscosity of the product is still lower than 3500 mPa s after 60 minutes; the post-curing speed is fast, which solves the problems of slow curing in winter; it can realize coating at room temperature and rapid curing at room temperature, significantly reducing Energy consumption, helping customers achieve cost reduction and efficiency improvement.

4. Aluminum plated structure has high composite strength

After the aluminized structure is combined, the aluminized transfer is prone to occur, which in turn leads to a decrease in peel strength. WANNATE® 6048A / WANEXEL® 748B effectively solve this problem. Taking the composite BOPP (ink)/VMPET structure as an example, after 24 hours of curing at room temperature, the composite effect is excellent, the ink does not transfer, the aluminum plating does not transfer, and the peel strength can reach 0.86 N/ 15mm, the composite strength of the aluminum-plated structure has increased by about 30% year-on-year, and the packaging barrier performance is excellent.

微信扫一扫打赏

微信扫一扫打赏