With the rapid development of marine transportation, oil and organic solvent leakage accidents occur frequently, causing serious pollution to the environment. A large area of oil pollution covering the sea will cause a large number of organisms in the sea to die due to lack of oxygen and destroy the marine ecological environment. Health hazard. How to remove crude oil and organic solvents from the sea has become a challenging problem. As a three-dimensional porous structure material, polyurethane foam has a wide range of applications in oil absorption. At present, the research on oil absorption of polyurethane foam mainly focuses on the surface modification of commercial foams. The raw materials for the synthesis of commercial polyurethane foams come from petroleum resources, which do not have the characteristics of green environmental protection. Therefore, it is of great importance to develop a biomass-derived and high-performance oil-absorbing material.

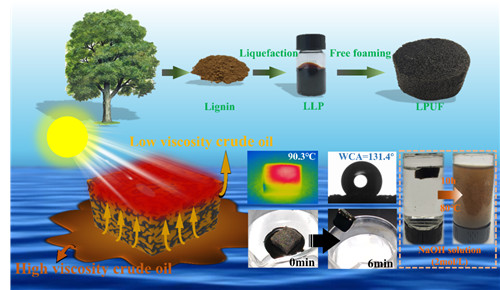

Fig.1 Lignin-based polyurethane foam composited with carbon nanotubes for efficient photothermal assisted crude oil recovery

Figure 2 Lignin-based polyurethane photothermal foam containing degradable Ti3C2Tx MXene nanosheets for rapid crude oil removal

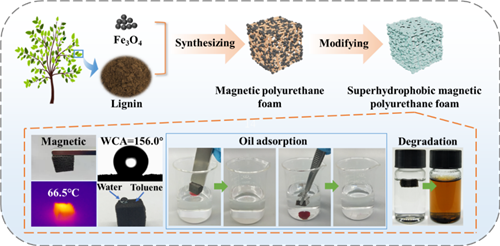

Fig.3 Superhydrophobic magnetic lignin-based polyurethane foam for heavy oil adsorption and efficient oil-water separation

Recently, researchers Chen Jing and Zhu Jin from the bio-based polymer materials team of the Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences cooperated with the team of Professor Yan Ning from the University of Toronto, Canada, and made achievements in the use of lignin-based polyurethane adsorbents in the treatment of marine oil spills. Related progress (Chem. Eng. J. 2021, 415, 128956; ACS Appl. Nano Mater. 2022, 5, 2848-2858; J. Water Process. 2022, 46, 102643).

The team first used a one-step method to prepare a carbon nanotube-composite lignin-based polyurethane crude oil adsorption foam for efficient crude oil recovery (Figure 1). The adsorbent uses a traditional polyurethane foaming process and the preparation method is simple. The prepared foam can have a surface temperature as high as 90°C under a single sunlight (1000W/m2), and recover crude oil more than 6 times its own quality within 6 minutes, and can be degraded in an alkaline environment, so it can be used as a green material in green projects. (Chem. Eng. J. 2021, 415, 128956)

Next, the team cooperated with researcher Huang Qing from the Advanced Energy Materials Engineering Laboratory to introduce MXenes nanosheets with better dispersion, higher photothermal conversion efficiency and degradability into the foam matrix (Figure 2). It was found that the bio-based syntactic polyurethane foam had a good light-to-heat conversion ability (50.1%). Under one solar illumination (1000W/m2), the highest surface temperature can reach 83°C, thus achieving efficient recovery of viscous crude oil. What’s more worth mentioning is that the material can be degraded in a 0.5mol/L sodium hydroxide/methanol mixed solution after being discarded, and the residue after degradation is mainly environmentally friendly substances containing titanium dioxide and carbon. (ACS Appl. Nano Mater. 2022, 5, 2848-2858)

On this basis, the team has developed a new type of superhydrophobic magnetic lignin-based polyurethane foam suitable for a variety of complex environments (Figure 3), because it can assist crude oil recovery with the help of light and heat under sunlight, and can be used in the absence of sunlight. Under the super-hydrophobic surface properties, it can realize conventional oil-water separation and has the characteristics of all-weather oil-water separation. The surface modification by silane makes it superhydrophobic, and the water contact angle is as high as 156°. The introduction of ferroferric oxide nanoparticles endows the foam with excellent photothermal properties and magnetic properties. Under a single sunlight (1000W/m2), the highest temperature on the foam surface can reach 66.5°C, and the adsorption capacity for crude oil is 4.89g/g. At the same time, due to the existence of ferroferric oxide, the foam has good magnetic properties, the saturation magnetization is 5.48emu/g, and the adsorbent can be driven and recovered by using a magnetic field. (J. Water Process. 2022, 46, 102643)

To sum up, the lignin-based polyurethane foam composite material designed and developed by the bio-based polymer team has excellent performance in the environmental treatment of organic solvent leakage or crude oil recovery, and can be degraded by a simple method after use. Environmental pollution is reduced to a minimum. This work not only finds an outlet for the application of lignin-based polyurethane foam, but also provides an idea for the application of bio-based polymer materials in the future.

The above work results have been supported by the National Key Research and Development Program (2017YFE0102300), OCE Project #29983 (Canada), National Natural Science Foundation of China (51902319, 31901263), Ningbo Public Welfare Science and Technology Program Project (202002N3127), etc.

微信扫一扫打赏

微信扫一扫打赏