Recently, the production technology of “Bio-based Biodegradable Hot Melt Pressure-Sensitive Adhesive” independently developed by Shenzhen Guanghua Weiye Co., Ltd. and its subsidiary Xiaogan Yisheng New Materials Co., Ltd. passed the national knowledge Approved by the Intellectual Property Office, obtained national invention patent authorization. At present, eSUN has applied for nearly 100 national patents and obtained more than 60 patents, mainly invention patents.

The patent authorization obtained this time represents the further improvement of eSUN’s environmentally friendly product matrix. In the future, this patented technology will help solve the problem of existing raw materials used to make hot melt pressure-sensitive adhesives that cannot be degraded under natural conditions and cause pollution. Serious problems can help the development of ecological and environmental protection in subtle ways.

1. About hot melt pressure-sensitive adhesive

hot melt pressure-sensitive adhesive

Adhesive (HMPSA) is a kind of thermoplastic elastomer as the main functional material. After blended with tackifying resin, softener and other additives, hot melt adhesive has the characteristics of solvent-free, pollution-free, low high temperature viscosity and easy to use. At the same time A type of adhesive that is pressure sensitive at room temperature. It is applied in a molten state, and after cooling and solidifying, it can be quickly bonded by applying light finger pressure. At the same time, it can be easily peeled off without contaminating the surface of the adherend.

2. eSUN polylactic acid polyol and its application in hot melt pressure-sensitive adhesive

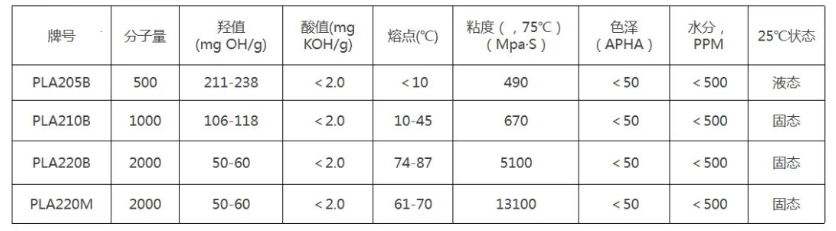

The raw material for preparing eSUN biodegradable hot-melt pressure-sensitive adhesive is mainly polylactic acid polyol. Polylactic acid polyol is the first product of eSUN and has been industrialized. As a synthetic and completely biodegradable thermoplastic aliphatic polyester polyol, the main raw material lactic acid is a renewable resource. It is non-toxic, non-irritating, has good biocompatibility, can be biodegraded and absorbed, and is ultimately completely Biodegrades into carbon dioxide and water.

Compared with traditional alkyd polyester polyols, polylactic acid polyols give polyurethane materials higher hardness and wear resistance, as well as higher hydrolytic stability, and are widely used in coatings, foams, elastomers and other fields. , is a raw material with excellent performance.

Replacing petroleum resins in the existing technology with biodegradable polymer polyols can further adjust the softening point and viscosity of the tackifying resin by controlling the molecular weight and molecular structure.

2. Performance and application of eSUN biodegradable hot melt pressure-sensitive adhesive

eSUN’s easily biodegradable hot-melt pressure-sensitive adhesive has good initial tack, excellent peel strength, no organic volatile solvents and good biodegradability.

Based on its excellent performance, eSUN biodegradable hot melt adhesive can be widely used in degradable packaging bags, labels, tapes, medical and hygiene products (such as band-aids), diapers and other care products.

The patent authorization granted this time demonstrates eSUN’s in-depth exploration in the industrialization direction of environmentally friendly materials and its continuous innovation in technology application. Based on the synthesis and modification of biological materials, eSUN has applied green and environmentally friendly products to many directions and fields such as biomedicine, 3D printing, ecological fibers, disposable degradable products, and green solvents. Through the original “X” configuration joint production innovation technology of bio-based materials, under one production line, eSUN can further realize the diversity of raw material sources and final products, enrich the production line functions, and effectively improve the production efficiency of the production system. Reduce production energy consumption and production costs.

微信扫一扫打赏

微信扫一扫打赏