Background and overview[1]

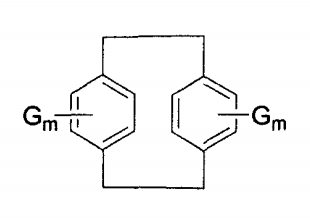

Diperized paraxylene (also known as parylene), as a new type of polymer functional material, is the general name for a class of polymers with paraxylene as the skeleton. The benzene ring or methylene ring of this polymer may be all hydrogen, or may contain various substituent groups. Parylene polymer can be prepared from its dimer. The dimer with two hydrogens on the methylene group has the following structure:

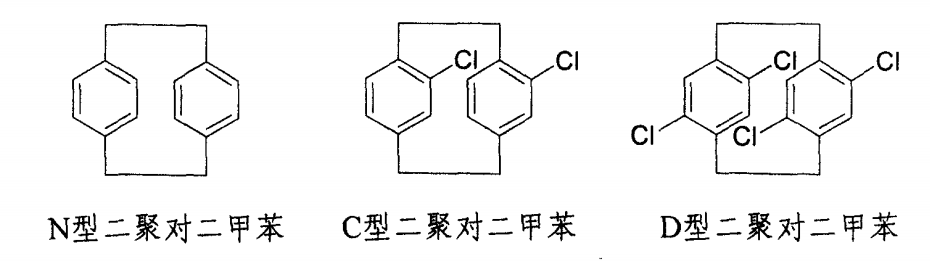

Wherein, m is an integer of 0, 1, 2, 3 or 4. When m is 2, G can be located at the ortho, meta or para position of the benzene ring; G is hydrogen, halogen or alkyl, and the halogen Can be F, Cl, Br or I. The most common dimers include the following structures:

Preparation[1]

Add 45g potassium carbonate, 58g potassium fluoride and 1.2g benzyltriethylammonium chloride into a 1L three-necked flask and dissolve them in 500mL water. Add a solution of 61.8g (2-chloro-4-chloromethylbenzyl)trimethylsilane dissolved in 100 mL toluene, and heat to 80~85°C with vigorous stirring for 3 hours. Cool, add 300mL of water to dilute, and separate the organic phase. The aqueous layer was extracted with 300 mL of toluene. The organic phases were combined, concentrated, and the crude product obtained was recrystallized with 100 mL of ethanol to obtain a total of 32 g of white powder C-type dimerized paraxylene, with a yield of 88%: HPLC 99.8%; mp 168-170°C; IR (KBr) 2933, 1588, 1543, 1483, 1435, 1396, 1191, 1044, 912, 848, 708, 655, 524cm-1; EIMS m/z 278(14.0), 276(20.7, M+), 140 (33.7), 138 (100.0, M/2+), 103 (29.2), 77 (20.0); Elemental Analysis Calcd for C16H14Cl2 C, 69.33; H, 5.09; Cl, 25.58, Found C, 69.53; H, 5.10; Cl, 25.56.

Add 48g sodium hydroxide, 168g sodium fluoride, 2.3g benzyltriethylammonium chloride into a three-necked flask and dissolve it in 800mL water, then add 213g (p-chloromethylbenzyl)trimethylsilane and 1000mL Toluene is added. Under vigorous stirring, the temperature was raised to 80°C and reacted for 2 hours. Cool and separate. The aqueous phase was extracted with toluene. Concentrate, and the crude product is recrystallized with ethanol to obtain 96g of white powder N-type dimerized paraxylene, with a yield of 92%: HPLC 99.6%; mp 287~289°C; 1H NMR (300MHz, CDCl3) δ6.47 (s, 8H), 3.06 (s, 8H) ppm; 13C NMR (75MHz, CDCl3) δ139.3 , 132.7, 35.4; IR (KBr) 2926, 1892, 1592, 1502, 1413, 1086, 936, 894, 806, 720, 622, 508cm-1; EIMS m/z 208 (22.2, M+), 104 (100.0, M/2+), 103(15.1), 78(13.8).

Apply[2-3]

Application 1,

CN201711198707.8 reports an organic fuel additive, including diaminoanisole, oleic acid diethylamide, coconut octanoic acid diethylamide, polyisobutylene diimide, lactic acid ester, dimer Toluene, tert-butyl alcohol and absolute ethanol, the mass parts of each component are: 25-40 parts of diaminobenzidine, 15-18 parts of oleic acid diethylamide, 10-15 parts of coconut octanoic acid diethylamide, 8-12 parts of polyisobutylene diimide, 10-16 parts of lactic acid ester, 10-15 parts of dimerized paraxylene, 18-22 parts of tert-butyl alcohol and 60-70 parts of absolute ethanol. The organic fuel additive described in the present invention has an effective chemical effect to clean up the overall fuel system, is suitable for new direct injection fuel systems, and can be used in any type of engines such as gasoline and diesel to remove gases from the combustion chamber and intake valve. Just pour the sediment into the fuel tank, effectively preventing stalling, improving fuel combustion efficiency and horsepower, and reducing emissions.

Application 2,

CN201611179063.3 discloses a high-efficiency composite additive for methanol gasoline and its preparation method, which is composed of the following mass parts of formula ingredients: 5-8 parts of diethanol formal, 6-8 parts of dimerized paraxylene, tetraethylene 5-6 parts of pentaamine, 2-4 parts of eicosanoic acid, 6-10 parts of tert-butyl methyl ether, 5-7 parts of n-heptane, 4-6 parts of propylene glycol butyl ether, 4-6 parts of isooctane, iso-octane 6-8 parts of octanol phosphate, 2-4 parts of nano-cobalt ferrite, and 3-4 parts of cocoate diethanolamide. The invention has the effect of significantly improving the water resistance of methanol gasoline and reducing the emissions of combustion NOX, HC, and CO. At the same time, the special formula also achieves the effect of increasing power and reducing fuel consumption to a certain extent.

References

[1] [Chinese invention] CN200510023332.2 Preparation method of dimerized para-xylene

[2] CN201711198707.8 An organic fuel additive

[3] CN201611179063.3 A high-efficiency composite additive for methanol gasoline and its preparation method

微信扫一扫打赏

微信扫一扫打赏