Background and overview[1]

O-chlorophenylacetic acid belongs to o-halophenylacetic acid. It is an important organic synthesis intermediate and can be used to synthesize many tricyclic compounds. Among them, o-chlorophenylacetic acid and o-iodophenylacetic acid can be used to synthesize anti-inflammatory and analgesic drugs. Diclofenac.

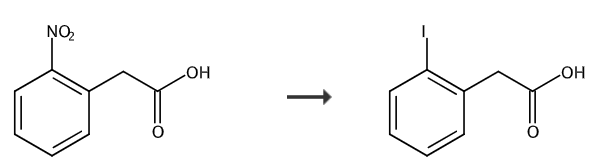

Preparation[1]

Synthesis of 1-nitrobenzene acetic acid

Add 10 mL of absolute ethanol into a two-necked flask equipped with a drying tube, and add 0.8 g (0.035 mol) of chopped metal sodium in batches under stirring. After the metal sodium is completely dissolved, cool to room temperature to obtain Anhydrous ethanol solution of sodium ethoxide. Add 4.4 g (0.03 mol) of diethyl oxalate and stir. After the materials are evenly mixed, add 4.1 g (0.03 mol) of o-nitrotoluene dropwise. Complete the addition in about 0.5 h. Then raise the temperature to 70°C and react for 1.0 h. Add it slightly cold. 15 mL of water, heated to reflux for 1.5 h. After hydrolysis is completed, unreacted o-nitrotoluene is recovered by steam distillation. Cool to room temperature, add 30% hydrogen peroxide dropwise, and continuously take the reaction solution and test it with sodium hydroxide solution. When the reaction solution does not change color when exposed to sodium hydroxide solution, it indicates that the reaction is complete. Cool the material to room temperature, acidify it to pH = 3 with hydrochloric acid, let it stand for crystals to precipitate, and filter it to obtain crude nitrobenzene acetic acid. Recrystallize with ethanol-water (volume ratio 1:3) to obtain 3.37 g of white needle-like crystals, yield 62%, melting point 137-139°C (140-141°C reported in the literature); infrared spectrum analysis (KBr tableting): 3 200 cm-1 (-COOH); 1 600 cm-1, 1 500cm-1, 1 450 cm-1 (benzene ring); 1550 cm-1 (NO2).

Synthesis of 2 anthranilic acid

Add 3.62 g (0.02 mol) o-nitrobenzene acetic acid, 0.4 g FeO(OH) and 10 mL 20% NaOH into a 100 mL flask, stir, raise the temperature to 80°C, and add 3.53 g 85% dropwise within 0.5 h. of hydrazine hydrate (0.06 mol), and then react for 0.5 h after adding. Add a little activated carbon for decolorization, suction filtration, and cool the filtrate with ice water for later use.

3 Synthesis of o-iodophenylacetic acid

Acidify the anthranilic acid solution to pH = 1 with sulfuric acid and then perform diazotization reaction. Add the diazo liquid dropwise to the potassium iodide-sulfuric acid solution (3.5 g KI, 1.0 mL concentrated H2SO4, 5 mL water) preheated to 60~70°C. medium, stir for 30 min, leave overnight, and filter to obtain the product. Recrystallize from 50% aqueous ethanol solution to obtain 3.83 g of o-iodophenylacetic acid, with a yield of 73% (based on o-nitrophenylacetic acid) and a melting point of 113-115°C (117°C reported in the literature). Infrared spectrum analysis (KBr tableting): 3150 cm-1(-COOH); 1 700 cm-1(-C=O); 1610 cm– 1, 1530 cm-1, 1450 cm-1 (benzene ring); 650 cm-1(-I). Mass spectrometry analysis, m/z: 262 (M+, 25%), 217 (36%), 135 (100%), 107 (24%), 91 (68%).

Main reference materials

[1] Cai Keying, Wang Taoxia, Gao Yuan, Li Xueli, Zong Zhimin, Wei Xianyong. Synthesis of o-halophenylacetic acid [J]. Progress in Chemical Engineering, 2006(10):1214-1216.

微信扫一扫打赏

微信扫一扫打赏