Background and overview[1]

1-(4-Fluorophenyl)-2-nitroethylene belongs to nitroalkenes, which are a class of biologically active compounds that are used in antibacterial, anticancer, antitumor or as cell signaling factors. Use important applications. Lajollamycin, a new antibiotic containing a nitroalkene structure isolated from marine sediments, exhibits antibacterial activity against methicillin-resistant Staphylococcus aureus and vancomycin-resistant enterococci. It can also inhibit the growth of mouse melanoma cells. grow. At the same time, nitro olefins can also be used for Michael addition, especially asymmetric Michael addition; nitro olefin cycloaddition reaction can be used to construct various cyclic compounds containing nitrogen substituents; hydrogenation reduction can also be used to Nitroalkenes are converted into various useful nitrogen compounds, etc.

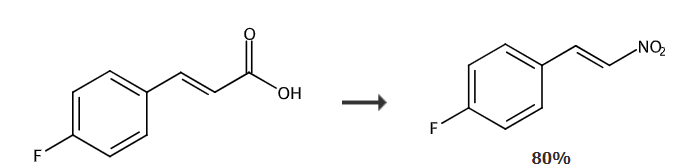

Preparation[1]

P-fluorostyrene (100mmol), TMSCl (4 equivalents, 400mmol), guanidine nitrate (2.2 equivalents, 220mmol), copper sulfate pentahydrate (0.1 equivalents, 10mmol), triethylamine (2 equivalents, 200mmol) and Acetonitrile (400 mL) was added to the 1000 mL Sneck bottle. First, add olefins, copper sulfate pentahydrate, and guanidine nitrate into the Snake bottle, then add acetonitrile, and finally add TMSCl. The reaction was allowed to stir well at room temperature for 24 hours and monitored by TLC. After the reaction is completed, filter, then add triethylamine to the filtrate, stir for 30 minutes, wash the mixture with water, and extract with DCM three times, then use a rotary evaporator to remove the solvent, and the result is 1-(4-fluorophenyl) -2-Nitroethylene.

This method uses copper salts such as copper sulfate pentahydrate, which are cheap and easily available on the market, as the catalyst, and cheap nitrates such as guanidine nitrate as the nitro source. In a one-pot reaction at room temperature, nitrification of olefin compounds can be achieved , not only has a high yield, but also can be scaled up to 10 grams or more, and has potential industrial application value. Compared with the existing technology, the raw materials are cheap and easy to obtain, the reaction conditions are mild, and no high-temperature heating is required, which greatly reduces the production cost, simplifies the production process, is conducive to industrial production, and is more economical and cheaper than the existing process for synthesizing nitroolefins.

Main reference materials

[1] [Chinese invention] CN201910294607.8 A method for preparing nitroalkene derivatives using nitrate as the nitro source

微信扫一扫打赏

微信扫一扫打赏