Background and overview[1-3]

2,2′-Diaminoethylene glycol diphenyl ether is a white crystalline powder with a melting point of 130-132°C. It is mainly used as the diazotization component for the synthesis of high-grade organic pigment yellow C.I.Pigment Yellow 180.

Preparation[1-2]

Report 1,

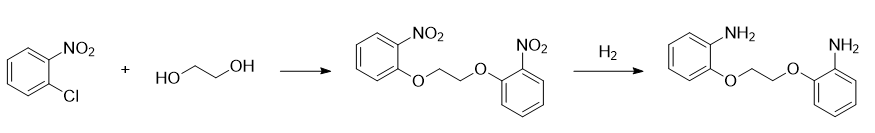

A preparation method of 2,2’-diaminoethylene glycol diphenyl ether, the synthesis route is:

Add 45g of 1,2-bis(2-nitrophenoxy)ethane, 1.3g of nickel catalyst, 1.8g of activated carbon, and 600ml of ethanol into a 1L high-pressure reaction kettle. After replacing it with nitrogen, start stirring to raise the temperature, and start flowing in hydrogen. The ventilation pressure is 0.4MPa, and the set temperature is 95°C. After the pressure no longer drops for 20-30 minutes, the hydrogenation reaction is completed, stop stirring and cool down to 65°C for hot suction filtration. The separated catalyst and activated carbon sets are passed to the next batch. The filtrate is cooled to 30°C for suction filtration, the filter cake is dried at 60°C, and the filtrate is used for the next batch. The molar yield is 90.03%, the purity is 99.09%, and the melting point is 130.8-131.4°C.

Report 2,

Add 60g of 1,2-bis(2-nitrophenoxy)ethane, 51.7g of 26% sodium hydrosulfide solution and 120g of water into a 1L high-pressure reaction kettle. After replacing with nitrogen, start stirring and raising the temperature. The set temperature is 130°C, the pressure is 0.2MPa, and the temperature is maintained for 5 hours. The reaction is completed. After the reaction is completed, the pressure is released, the temperature is lowered, and filtered at 30-35°C to obtain the crude product. The crude product was dissolved in hydrochloric acid using 300 ml of water as solvent, then refined with liquid alkali and dried to obtain 44.4 g of product; molar yield 91.0%, purity 99.65%, melting point 131-131.4°C.

Apply[3-4]

CN201310277489.2 reports a preparation method of a transparent green light yellow pigment C.I.P.Y180, which belongs to the field of pigment preparation technology. Green light yellow pigment Y180 is mainly used in the plastic and coating industries. The method includes the following steps: 1) using 2,2”-diaminoethylene glycol diphenyl ether and 2,2”-diaminoethylene glycol diphenyl ether to prepare a diazonium salt solution; 2) using 5-acetyl Prepare a coupling component solution using acetamido benzimidazolone and potassium hydroxide; 3) Use acetic acid and sodium acetate to form a buffer solution, drop the diazonium salt solution and the remaining coupling component solution, and continue stirring after the addition is complete to wait for coupling. The reaction is complete, and the crude pigment is obtained by filtration; 4) Add the crude pigment into the pigmentation reactor, add additives and water, heat it up, and finally filter, dry, and grind to obtain the finished pigment. The present invention not only reduces the use of organic solvents and has simple reaction conditions, but also significantly improves the transparency of pigments. At the same time, it greatly reduces energy consumption, lowers costs, reduces the use of flammable and explosive materials, and improves safety. It has very good economic benefits.

CN201310615681.8 reports a fabric insect-proof and antibacterial finishing agent, including the following raw materials in parts by mass: 10-12 parts of sodium tetrachlorodihydroxytriphenylmethanesulfonate, 5-8 parts of ethyl p-hydroxybenzoate parts, 6-8 parts of 2,2′-diaminoethylene glycol diphenyl ether, 1-5 parts of sucrose fatty acid ester, 50-70 parts of ethylene glycol, and 68-74 parts of water; the sucrose fatty acid ester is Sucrose laurate or sucrose dilaurate. The anti-insect and anti-bacterial finishing agent for fabrics of the present invention has a remarkable anti-insect effect, can effectively repel insects and protect the integrity of fabrics. The present invention also has good anti-bacterial properties and can inhibit the growth of bacteria and mold. The present invention has a reasonable formula and has no toxic or side effects on the human body. Can be promoted and applied.

References

[1] [Chinese invention, Chinese invention authorization] CN201310691351.7 A preparation method of 2,2’-diaminoethylene glycol diphenyl ether

[2] [Chinese invention] CN201610257638.2 A method for preparing 2,2′-diaminoethylene glycol diphenyl ether by reduction with sodium hydrosulfide

[3] [Chinese invention] CN201310277489.2 Preparation method of transparent green light yellow pigment C.I.P.Y180

[4] [Invented in China] CN201310615681.8 Insect-proof and antibacterial finishing agent for fabrics

微信扫一扫打赏

微信扫一扫打赏