Background and overview[1][2]

2-Cyanobenzaldehyde is an aromatic nitrile compound. Aromatic nitrile compounds are a very important class of organic synthesis intermediates and are widely found in medicines, pesticides, herbicides, insecticides, dyes, spices and natural products. For example, 2,4-dinitro-6-cyanoaniline, which can be used to make excellent bright blue diazo dyes, and the international new nitrile spice lemon nitrile, which has a sharp and strong lemon-like aroma. In addition, the cyano group is a type of functional group containing a carbon-nitrogen triple bond. It has a short bond length, a relatively small volume (about 1/8 of the methyl group), strong polarity and strong electron-withdrawing properties. Therefore, The cyano group is a good hydrogen bond acceptor, allowing it to penetrate deep into the target protein and form strong hydrogen bond interactions with key amino acids in the active site; at the same time, the cyano group is also used in activity studies due to its Metabolic stability and bioisosteres as functional groups such as hydroxyl and carboxyl groups can enhance the interaction between small drug molecules and target proteins, and are therefore widely used in medicinal chemistry research.

Preparation method[1][2]

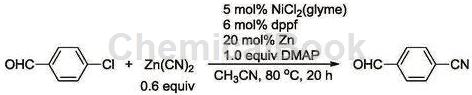

Method 1: Under argon protection, add NiCl2(glyme) (0.05mmol, 11.0mg), dppf (0.06mmol, 33.3mg), Zn (0.2mmol, 13.0mg) in sequence to a 25.0mL sealed tube. DMAP (1.0mmol, 122.2mg), Zn(CN)2 (0.6mmol, 70.5mg), p-chlorobenzaldehyde (1.0mmol, 140.6mg) and acetonitrile (5.0mL), and then placed directly into an 80°C oil bath During the reaction, stop heating after 20 hours, cool to room temperature, filter the reaction solution directly through a short silica gel column, rinse with dichloromethane, concentrate, and directly purify by silica gel column chromatography (in view of the fact that most of the product is easily pumped away, in order to avoid stirring Sample loss, unless otherwise specified, all samples are loaded by wet method.) Eluent: petroleum ether/ethyl acetate = 10:1, the product is 114.3 mg of white solid 2-cyanobenzaldehyde, yield 87%, 1HNMR Purity is greater than 98%.

Method 2: Add 4g o-cyanotoluene, 0.426g cobalt acetate, 0.096g sodium bromide and 10g 99% glacial acetic acid into a 100ml three-neck flask, stir electromagnetically, and control the reaction temperature at 105°C for 5 minutes. At this temperature, oxygen 4L/h was introduced and the reaction was carried out for 5 hours. After the reaction is completed, the reaction solution is cooled to room temperature, and 30g of water is added. Separate the liquids, separate the organic layer, extract the aqueous layer with diethyl ether (20g×3), and combine the organic layers. The organic layer was back-extracted with saturated sodium bisulfite aqueous solution (50g×4). The extract was adjusted to pH=11 with 5% NaOH solution, and extracted with diethyl ether (20g×3). The ether layer was dried and evaporated to dryness to obtain 2-cyano. Benzaldehyde 2.91g, yield 65.0%.

Main reference materials

[1] CN201710154605.X Preparation method of aromatic nitriles or heteroaromatic nitrile compounds

[2] CN01105686.X A method for preparing cyanobenzaldehyde (o-one, meta-one, pair-one,)

微信扫一扫打赏

微信扫一扫打赏