Background and overview[1][2]

Meta-chloroacetophenone is an organic intermediate that can be prepared from benzoyl chloride as the initial raw material and can be used to synthesize 2,3’-dichloroacetophenone.

Preparation[1]

The benzoyl chloride is first chlorinated to generate m-chlorobenzoyl chloride, and then reacts with diethyl ethoxymagnesium malonate to generate m-chlorobenzoyl diethyl malonate, and finally undergoes hydrolysis and decarboxylation to generate m-chlorobenzoyl chloride. Chloroacetophenone. Using m-chlorobenzoyl chloride as raw material, m-chloroacetophenone is prepared through the following three-step reaction.

The first step of the reaction is to use anhydrous ether as the solvent, carbon tetrachloride as the initiating catalyst, and heat and reflux from magnesium, absolute ethanol and diethyl malonate at normal pressure and 20°C to 35°C. 2 to 4 hours to prepare diethyl ethoxymagnesium malonate, the conversion rate of diethyl malonate can reach 85% to 90%; the second step reaction uses anhydrous ether as the solvent, under normal pressure At a temperature of 30°C to 35°C, diethyl ethoxymagnesium malonate reacts with m-chlorobenzoyl chloride to produce diethyl m-chlorobenzoylmalonate, and the conversion rate of m-chlorobenzoyl chloride reaches 90 %, the selectivity can reach 85%; the third step of the reaction is to hydrolyze diethyl m-chlorobenzoylmalonate in a sulfuric acid aqueous solution at normal pressure and a temperature of 90°C to 110°C with heating and reflux for 3 to 5 hours. And decarboxylation produces m-chloroacetophenone, and the hydrolysis decarboxylation rate is almost 100%. The reaction mixture after hydrolysis and decarboxylation can be separated by distillation to obtain m-chloroacetophenone with a content of ≥99%, and the product yield can reach 75% to 85%.

Apply[2-3]

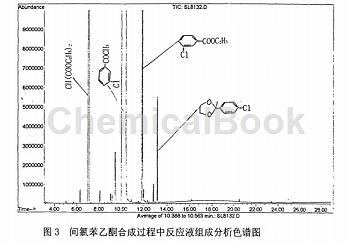

One, 2,3’-dichloroacetophenone is an important organic raw material and can be used to synthesize pharmaceutical raw materials and other organic compounds. CN200810021236.8 provides a method for synthesizing 2,3′-dichloroacetophenone, which is characterized in that m-aminoacetophenone is used as raw material, and m-acetophenone diazo hydrochloride is generated through diazotization reaction; The Sandmay reaction generates m-chloroacetophenone; the α-chlorination reaction generates 2,3′-dichloroacetophenone.

The present invention is realized by the following methods:

The first step is to prepare 2.0 to 4.0 mole parts of hydrochloric acid, add 1.0 to 1.1 mole parts of m-aminoacetophenone, and cool it to 0-5°C with ice salt water while stirring to obtain m-aminoacetoethyl The ketone hydrochloride aqueous solution is ready for use. In addition, prepare 1.0 to 1.2 molar parts of sodium nitrite aqueous solution, and add it dropwise to the above solution from below the liquid surface. Keep the reaction temperature at 0 to 5°C. After the dropwise addition is completed, continue the incubation reaction for more than 30 minutes to obtain m-acetophenone diazonium salt solution.

The second step is to pour the diazonium salt solution prepared above into the prepared cold 1.0 to 1.5 molar CuCl hydrochloric acid solution, heat to 40 to 65°C, stir thoroughly and leave for 2 to 3 hours, then separate. The solid material and water phase were removed to obtain an oily substance. Wash the oil with water until the aqueous solution becomes neutral. Add the oil to water and distill it with steam until there are no oil droplets. Separate the oil layer, and extract the water layer with benzene. After combining the oil layers, first evaporate the benzene under normal pressure, and then collect the 100-102°C (2.6kp) fraction under reduced pressure to obtain m-chloroacetophenone.

The third step is to add 1.0 to 1.03 mole parts of m-chloroacetophenone, 4.0 to 6.0 mole parts of acetic acid and 0.002 to 0.01 mole parts of the catalyst benzoyl peroxide into the three-necked bottle, and fill it Reflux tube and thermometer, heat to reflux for 3 hours, add 0.001 to 0.005 mole parts of catalyst, and continue to reflux for 3 hours. After evaporating most of the acetic acid, pour a large amount of water and stir to obtain a brown oily crude product 2,3’-dichloroacetophenone. Filter and wash, and then recrystallize using benzene as a solvent to obtain white needle-like crystals of 2,3’-dichloroacetophenone (mp: 35~37°C).

2. m-Chloroethylbenzene is a colorless liquid, mainly used as an intermediate in organic synthesis. CN200710021387.9 provides a synthesis method of m-chloroethylbenzene, which does not require distillation and has a simple process, high yield and purity, and is economical.

The task of the present invention is accomplished in this way, a synthesis method of m-chloroethylbenzene, which includes the following steps: A). Using m-chloroacetophenone as raw material, react with hydrazine hydrate to reflux to generate hydrazone, and cool Then separate layers to obtain the hydrazone; B). Co-thermally react the hydrazone in a diethylene glycol solution of potassium hydroxide or sodium hydroxide to generate crude m-chloroethylbenzene; C). Distill the crude m-chloroethylbenzene, The finished product m-chloroethylbenzene is obtained, wherein: the reflux reaction is a reflux reaction under normal pressure, the reaction time is 120-180 min, the reaction temperature is 107-119°C, and the reaction temperature of the cothermal reaction is 110-148 ℃, reaction time is 90-180min.

One of the advantages of the method of the present invention is that the process is simple because no distillation is required; secondly, the reaction conversion rate is high and the by-products are small, so that the yield of m-chloroethylbenzene can reach 95-97%; Third, the purity can reach 98.6-99%; fourth, it can be put into industrial production and is economical.

Main reference materials

[1] CN01127165.5 Synthesis of m-chloroacetophenone from benzoyl chloride

[2] CN200810021236.8 A synthesis method of 2,3’-dichloroacetophenone

[3] Synthesis method of CN200710021387.9 m-chloroethylbenzene

微信扫一扫打赏

微信扫一扫打赏