Background and overview[1]

Phenyl alkyl sulfonate is a light yellow oily transparent liquid, with a freezing point of <-10 ℃, a boiling range of 211 ℃ to 279 ℃ (1 333 Pa), a relative density of 1.05 to 1.07 (20 ℃), and a refractive index of 1.494 to 1.500 ( 20 ℃), flash point (open cup method) 200 ℃ ~ 220 ℃, viscosity 0.10 ~ 0.13 Pa·s, thermal evaporation <0.2% (100 ℃, 6 h). Non-toxic. .

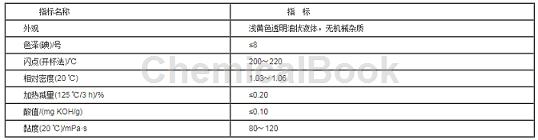

Product standards[1]

Preparation[1]

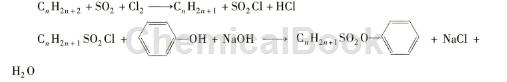

After the heavy liquid paraffin from C12 to C18 is dehydrated with oleum, sulfur dioxide and chlorine are metered through the flow meter to carry out sulfonyl chlorination. . The reaction is carried out under light, the reaction temperature is about 30 ℃, and the conversion rate is about 50%. After removing the residual hydrogen chloride from the product, it is esterified with phenol in the presence of caustic soda. The reaction temperature is about 50 ℃ to generate phenyl alkyl sulfonate. . The esterified product is left to separate the aqueous layer, and 20% caustic soda is used to extract phenol at about 70°C. Then hot steam is introduced for vacuum distillation to remove unreacted alkanes. The temperature of the tower kettle is 190°C ~ 210°C, and the vacuum degree is not Less than 0.085 MPa. The crude ester is decolorized with sodium hypochlorite, washed with water, vacuum dehydrated, and suction filtrated to obtain the finished product. The reaction formula is as follows:

Purpose[1-6]

The auxiliary plasticizer or incremental plasticizer of polyvinyl chloride has low volatility, low cost and non-flammability. It can give the product certain weather resistance, physical and mechanical properties, electrical insulation and flame retardancy. It is often used with Phthalate-based main plasticizers are used in leather making, films, cable materials, shoe sole materials, etc., replacing some of the main plasticizers and reducing costs. Examples of its application are as follows:

1) Prepare a heat-baked migration-resistant peelable blue glue. A heat-baking type migration-resistant peelable blue glue, which is characterized in that it is composed of chlorine vinegar resin, chlorinated polyvinyl chloride, alkyl phenyl sulfonate plasticizer, polyester plasticizer, heat stabilizer, and defoaming agent , leveling agent, lubricant, fumed silica and toner. The parts by weight of each raw material are: 45-60 parts of chlorine-vinegar resin, 5-10 parts of chlorinated polyvinyl chloride, alkyl sulfonate 20-35 parts of acid phenyl ester plasticizer, 10-15 parts of polyester plasticizer, 0.75-1.25 parts of heat stabilizer, 0.5-1.0 parts of defoaming agent, 1.0-1.5 parts of leveling agent, 1.0-1.5 parts of lubricant parts, fumed silica 0.5-0.75 parts, toner 0.3-0.7 parts. The peelable blue glue prepared by the invention has good flexibility and can achieve large-area peeling. At the same time, it can effectively suppress the reduction of plasticizing efficiency caused by plasticizer migration, ensuring the storage of the peelable blue glue.

2) Prepare a polyvinyl chloride plastic cable guide, including the following raw materials by weight: 100 parts of polyvinyl chloride resin, 20-30 parts of raw rubber, 20-30 parts of phenyl alkyl sulfonate, phthalate 35-55 parts of dioctyl formate, 30-80 parts of calcium carbonate, 50-60 parts of chlorinated paraffin, 5-10 parts of flame retardant, 5-10 parts of zinc borate, 3-5 parts of clay, 1-3 color masterbatch share. The invention uses a mixture of polyvinyl chloride resin, raw rubber, and phenyl alkyl sulfonate, which effectively improves the performance of the product and reduces the quality of the product; it has superior corrosion resistance and excellent resistance to acid, alkali, salt and other chemical solvents. It resists corrosion, does not crack when exposed to grease, and can adapt to various working environments; the invention has high strength, heat resistance, long service life and excellent electrical performance.

3) Preparation of water-soluble diffusing agent, which involves the application technology of alkyl phenyl sulfonate (salt) or/and alkyl fatty acid phenyl ester (salt). The main component of this diffusing agent is a mixture of alkyl phenyl sulfonate (salt) or/and alkyl fatty acid phenyl ester (salt) and OP-10, and the auxiliary agents are phosphoric acid, triethanolamine, ethanol, urea, and insurance powder. It is best used when the pH value is adjusted to 7-9 with caustic soda. This product is not only a good diffusing agent, but also has excellent emulsifier, cleaning agent, penetrating agent, leveling agent and other effects. It is easy to prepare, cheap and widely used.

4) Preparing a moisture-proof wall includes the following steps: combining ethylene glycol diacrylate, hydroxyethyl methacrylate, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, Add polyvinyl alcohol into the chemical kettle, stir evenly, pressurize to 0.2-0.3MPa, and maintain the pressure for 1.5-2 hours to obtain a composite mother liquor; the interface agent provided by the invention adds microsilica powder and silane-terminated polyvinyl alcohol. Ether, phenyl alkyl sulfonate, and phenyl maleimide-based silicone resin improve the bonding strength between the interface agent and the wall. The interface agent can withstand the load acting on the wall. At the same time, the interface agent also has good impermeability. , and it has a good combination effect with the plastering mortar of the present invention, which increases the overall strength and moisture-proof performance of the wall. It has good fluidity and is easy to construct.

5) Prepare an advertising art design LED display plastic shell material, consisting of the following components: asphalt, mugwort leaf extract, methylaniline, diphenylmethane diisocyanate, perchlorethylene resin, clove, fluorotitanium Potassium sulfate, calcium sulfate dihydrate, sesame oil, methyl benzoate, aluminum distearate, methyl benzoate, molybdenum oxide powder, fluorocarbon resin, polychlorinated biphenyls, hexabromocyclododecane, decabromide Diphenyl ether, propiconazole, salicylanilide, white beeswax, white corundum powder, sodium humate, high aluminum fine powder, potassium aluminum sulfate dodecahydrate, propylene glycol methyl ether acetate, dipropylene glycol methyl ether, butyl Dibutyl enedioate, ammonium zirconium carbonate, tung oil anhydride, phenyl alkyl sulfonate. The product of the present invention has relatively superior�’s flame retardant, acid and alkali resistance, mildew resistance and antibacterial properties improve product performance.

Main reference materials

[1] Practical Chemical Formulations Manual

[2] CN201210423094.4 A heat-baked migration-resistant peelable blue glue and its preparation method

[3] CN201410328987.X A polyvinyl chloride plastic cable guide

[4] CN92105876.4 water-soluble diffusing agent

[5] CN201810413533.0 A moisture-proof wall construction method

[6] CN201610552920.3 An advertising art design LED display plastic shell material

微信扫一扫打赏

微信扫一扫打赏