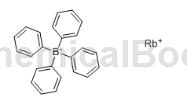

Overview[1]

Rubidium tetraphenylborate is a typical large anion strong electrolyte with a similar molecular structure and the same crystal form. The thermodynamic properties of solution systems containing large anion rubidium tetraphenylborate have received widespread attention. Many authors have studied tetraphenylrubidium borate. The thermodynamic properties of rubidium phenylborate in solution were studied. Rubidium tetraphenylborate is different from other salts of the same family (such as K, Rb and Cs) in that it is easily soluble in water and common organic solvents. Since it was synthesized by Witting in the early 1950s, it has been widely used in inorganic analysis, organic analysis and chemical synthesis. It has been widely used in other fields.

Preparation[2]

Add 25 mL of water, methanol, ethanol, propanol, butanol, pentanol, hexanol, heptanol, octanol and excess rubidium tetraphenylborate to nine 50mL ground-mouth solubility bottles respectively, and shake well. Then use N2 to remove oxygen, seal it and place it in a super constant temperature bath (temperature control accuracy is ±0.1K), oscillate once every 2 hours. Depending on the temperature, the equilibrium time is 8 to 10 days.

Determination of standard curve equation

Rubidium tetraphenylborate has two obvious absorption peaks at 275nm and 266nm in pure water and linear monohydric alcohol solutions. 275nm is selected as the measurement wavelength during measurement. Prepare a series of BPh4 solutions with different concentrations. The absorbance A is measured on a UV-365 spectrophotometer at a wavelength of 275nm, and the absorbance A is used to perform a linear regression on the rubidium tetraphenylborate concentration C (mol–L-1) on a microcomputer. The standard curve equation is:

A=2.0543X103C+4.52×10-4(1) The correlation coefficient is 0.9996.

Determination of solubility of rubidium tetraphenylborate

Filter the above saturated solution of rubidium tetraphenylborate to remove the undissolved rubidium tetraphenylborate. Pay attention to the filtration temperature and its equilibrium temperature. The absorbance A at the wavelength of 275nm is measured in the saturated solution obtained by the formula ( 1) Calculate its concentration and convert it to the solubility of rubidium tetraphenylborate.

Apply[3]

Enantiopotential sensor

Weigh 4 parts of rubidium tetraphenylborate, 64 parts of plasticizer “DBS” and 32 parts of PVC by weight, and dissolve them in 600 parts of tetrahydrofuran; when each component is completely dissolved, pour the solution onto a glass plate Expand naturally and obtain a PVC film after leaving it at room temperature for 24 hours; stick the prepared PVC film to one end of a PVC pipe with an inner diameter of 8mm, an outer diameter of 10mm, and a length of 10cm using a tetrahydrofuran solution with a PVC concentration of 8%, and place it For 10 minutes, after the solvent has completely evaporated, pour the KCl filling liquid into the tube, insert the Ag/AgCl internal reference electrode, and obtain the PVC membrane electrode; combine the PVC membrane electrode and the calomel electrode to form the required enantiomeric potential sensor. The sensor expression is as follows:

Hg-Hg2Cl2︱KCl(satd.)|Test solution︱PVC membrane︱0.1mol·L-1KCl|AgCl-Ag.

Copolymerization of formaldehyde and cyclic ether as initiator of rubidium tetraphenylborate

The reaction was carried out in a 250 ml Erlenmeyer reaction flask and samples were collected continuously as overflow. The initial loading was 140 g heptane (water content 8.4 ppm) and 60 g dry, acetate-terminated polyoxymethylene in the form of particles having a particle size of about 200 microns. After an initial temperature of 48°C and saturation with formaldehyde, the raw materials were continuously added, including 1 ml/hr of a 0.28 M solution of rubidium tetraphenylborate in dichloromethane, 0.1 g/min of dioxolane, and 6 g/min of dioxolane. of heptane. The temperature stabilized at about 61°C at a polymerization rate of 1.7 g/min. Samples were taken at 20 minute intervals over a 2 hour period and the reaction was run for a total of 170 minutes. The solution contained 0.6-1.7% by weight (average about 1%) dioxolane, 0.06-0.08 1,3,5-trioxane, and no trioxepane was detected throughout the run. The mole percentage of dioxolane ranged from 1.04 to 1.6 mole % in the intermediate sample and 1.70 mole % in the final product. The copolymer is 77.6-80.5% by weight alkali stable, Mn is 36-38000, and Mw is 114-117000.

Main reference materials

[1] Li Dacheng, Wen Luxin, Wang Yong, & Liu Daojie. (1998). Standard migration thermodynamic function of rubidium tetraphenylborate from water to linear monohydric alcohol. Acta Chimica Sinica, 56(9), 859- 866.

[2] Wang Yong, Liu Fengzhang, Zhao Zhixue, & Li Dacheng. . Use neural network to calculate the standard migration thermodynamic function of rubidium tetraphenylborate from water to linear monohydric alcohol. Journal of Liaocheng University (Natural Science Edition) (4 ), 42-45.

[3] Li Dacheng, & Mao Hongyu. . Four��Solubility and association thermodynamic function of rubidium borate in methanol-water mixed solution. Journal of Liaocheng Normal University: Natural Science Edition, 11(3), 51-55.

微信扫一扫打赏

微信扫一扫打赏