Background and overview[1]

2,4-Dichloro-6-nitrophenol can be used as a pharmaceutical synthesis intermediate. For example, it can be used to prepare Oxyclozanide, also known as Oxyclozanide, Oxyclozanide and Oxyclozanide. It is a halogenated salicylanilide compound and a salicylanilide anthelmintic. Drug, currently mainly used to treat and control trematodes in cattle, sheep and other animals. Similar to other salicylanilide anthelmintics, pentclosamide is an oxidative phosphorylation uncoupling agent. Its mechanism of action is to inhibit the phosphorylation process of mitochondria in the insect body and prevent the production of adenosine triphosphate (ATP), which is energy, in the insect body. , thus causing the insect to die due to energy metabolism disorders. The main application methods of Penclosamide are: as an oral once-in-a-dose alone, in combination with levamisole hydrochloride or oxfendazole, or in powder form mixed into feed. In recent years, it has been discovered that pentclosamide not only has a good anthelmintic effect against Fasciola hepatica in cattle and sheep, but is also active against tapeworms and nematodes. It has low toxicity and no residue, so it has been widely used in the anthelmintic drug market.

Preparation[1]

The preparation of 2,4-dichloro-6-nitrophenol is as follows:

The specific steps are as follows: Put 48.9 grams (0.3 mol) of 2,4-dichlorophenol (compound 1) into a clean 250ml beaker, add 60g of methanol, stir with a glass rod until dissolved, and put into a 500ml four-necked flask 280g (1.0mol) of 15% nitric acid, start stirring, add the above methanol solution of 2,4-dichlorophenol dropwise at 25°C for about 4 hours, complete the dripping, keep the reaction for 2 hours, when the reaction is completed, distill the methanol away, and the remaining The reaction solution was cooled to 10°C, and kept for 30 minutes for crystallization. It was suction filtered, and the filter cake was washed with 100 ml of water and dried at 55°C for 5 hours to obtain 59.7g of yellow solid, with a yield of 95.7%, a purity (GC) of 99.9%, and a melting point of 118-120 ℃, 2,4-dichloro-6-nitrophenol is obtained.

Apply[1]

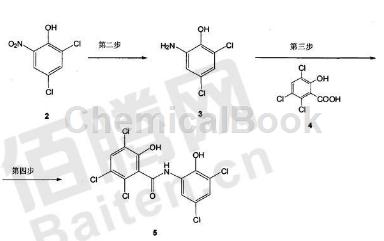

2,4-Dichloro-6-nitrophenol can be used as an intermediate in pharmaceutical synthesis, such as the synthesis of penclosamide:

Step 1: Put 41.6g (0.2mol) of the above-mentioned 2,4-dichloro-6-nitrophenol, 185g methanol, 2.1g ferric chloride and 5.8g activated carbon into a dry 500ml four-necked flask. Start stirring, raise the temperature to reflux, and reflux for 10 minutes until stable. Slowly add 29.5g (0.5mol) of 85% hydrazine hydrate dropwise for about 2 hours. After the dripping is completed, continue to reflux for 1 hour. Cool to 50°C and filter to remove the activated carbon. Distill the mother liquor and evaporate about 140g of the solvent methanol. After the distillation, slowly add 300ml of water dropwise. During the process, a yellow-gray flocculent solid will precipitate for about 2 hours; cool to 15°C and keep stirring for 30 minutes. Filter with suction and use 200ml of water for the filter cake. Wash and dry at 45°C for 8 hours to obtain 32.5g of yellow-gray flocculent solid, yield 91.3%, purity (HPLC) 99.3%, to obtain 2-amino-4,6-dichlorophenol (compound 3); HPLC conditions ( BP2003): Mobile phase A: 0.1% v/v phosphoric acid aqueous solution, B: methanol; flow rate: 2.0ml/min; injection volume: 10μL; wavelength: 300nm; column temperature: 25℃;

Step 2: Put 380g of chlorobenzene, 36.6g (0.152mol) of 3,5,6-trichlorosalicylic acid and the above-mentioned 2-amino-4,6-dichloro into a dry 500ml four-necked flask. Phenol (compound 3) 26.7g (0.15mol), start stirring, heat to reflux until the material is completely dissolved, slowly add 18.9g thionyl chloride (0.159mol) dropwise under reflux for about 3 hours, the tail gas generated in the process is Absorb liquid caustic soda; after dropping, continue the reflux reaction for 2 hours, slowly cool to 10°C for about 2 hours, filter with suction, wash the filter cake with 250ml of toluene, and dry at 55°C for 6 hours to obtain 58.4g of brown solid, with a yield of 97.0%, that is It is Pentachloramide (compound 5, also known as 2,3,5-trichloro-N-(3,5-dichloro-2-hydroxyphenyl)-6-hydroxybenzamide);

Step 3: Refining the above-mentioned pentclosamide: add 256g of methanol, 40.0g of the above-mentioned pentclosamide (compound 5) and 2.0g of activated carbon into a dry 500ml four-necked flask, start stirring, and heat to Reflux and keep it warm for 30 minutes; cool to 50°C, filter to remove activated carbon, distill the mother liquor until a yellow solid precipitates, evaporate about 180g of the solvent methanol, cool to 10°C, and keep the temperature for 2 hours to crystallize, filter with suction, and use for filter cake Rinse with a small amount of methanol and dry at 55°C for 4 hours to obtain 25.9g of light yellow powder, yield 64.7%, purity (HPLC) 99.7%, melting point 207~209°C.

Main reference materials

[1] CN201010221964.0 Preparation method of penclosamide

微信扫一扫打赏

微信扫一扫打赏