Background and overview[1]

The photoinitiator EHA (isooctyl p-dimethylaminobenzoate, trade name ESCALOL507) is a good UV absorber in the UVB region, and its maximum UV absorption peak is 311nm (ethanol solution). As an anti-ultraviolet active ingredient, it is widely used in sunscreen cosmetics abroad in huge amounts. The U.S. FDA lists sunscreen containing this product ingredient as the first category of recommended cosmetics. Currently, as my country’s sunscreen product market continues to develop rapidly year by year, the raw material of isooctyl para-dimethylaminobenzoate (photoinitiator EHA) needs to be imported from abroad every year to be used as an anti-aging agent for industrial products. Therefore, it is of great practical significance to carry out research on the synthesis process of isooctyl p-dimethylaminobenzoate (photoinitiator EHA), and it will also help to realize the localization of the product.

Apply[1-2]

Photoinitiator EHA is a type of highly efficient amine accelerator, used together with free radical (II) type photoinitiators. It is mainly used for UV curing of varnish coating systems on paper, wood, metal and plastic surfaces. It can also be used It is also an excellent sensitizer for the UV radiation polymerization of single or multiple monomers. It is often used in combination with thioxanthone photoinitiators and acetophenone photoinitiators to promote photoinitiation. It can also effectively eliminate the interference of oxygen on photoinitiated polymerization. Photoinitiator EHA can be used as an excellent anti-UV additive and is widely used in water-resistant sunscreen cosmetics, including isopentyl para-dimethylaminobenzoate (IADB) and isooctyl para-dimethylaminobenzoate (photoinitiator EHA ) (EHA, trade name 507), which is a good UV absorber in the UVB area. As a sunscreen, it is widely used internationally. The US FDA lists it as the first recommended sunscreen. . Para-dimethylaminobenzoate is not only used in the field of cosmetics, but also can be used as a preservative, such as: methyl para-dimethylaminobenzoate, propyl para-dimethylaminobenzoate, n-butyl para-dimethylaminobenzoate Both its solutions have antiseptic properties.

Preparation[2]

Using N, N-dimethyl p-aminobenzoic acid and isooctyl alcohol as raw materials, without solvent dehydration, using p-toluenesulfonic acid as the esterification catalyst, A high negative pressure method is used to remove the water generated during the reaction, so that the positive reaction can proceed to the maximum extent, and the reaction temperature is controlled at 110~120℃. The focus was on the esterification reaction conditions without solvent participation: reaction temperature 110~120℃, vacuum degree -0.095MPa, reaction time 6h, and the molar ratio of p-dimethylaminobenzoic acid to isooctyl alcohol is 1:3.5, based on p-dimethylaminobenzoic acid, the product yield is 90%.

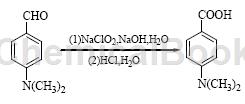

Step 1: Synthesis of p-dimethylaminobenzoic acid

Dissolve 149g (1mol) of p-dimethylaminobenzaldehyde in 600mL toluene, keep the system temperature at 5~10℃, add 6.5gKH2PO4 and 100mL water, and add NaClO2 dropwise ( 1.35mol, 122.2g) and 1000mL of aqueous solution, add it dropwise in 1.5h, then keep it warm for 3h, stir and raise the temperature to 25~30℃,

React for another 3 hours and follow the reaction with TCL. Then 1000 mL of 10% NaOH solution was added to the reaction mixture. This alkaline aqueous solution was extracted with chloroform (2×400mL, 1×200mL). The remaining aqueous solution was cooled with an ice bath. Use 4 mol/L hydrochloric acid to adjust the pH value to 2 to 3, filter the solid obtained, wash with water and ethanol, and dry to obtain 142 g of white solid, with a yield of 86%. The melting point is 240~241.5℃ (recrystallized from ethanol), and the NMR spectrum is consistent with the standard spectrum.

Step 2: Synthesis of isooctyl p-dimethylaminobenzoate (photoinitiator EHA)

Add 150g of homemade p-dimethylaminobenzoic acid, 525g of isooctyl alcohol and 35g of p-toluenesulfonic acid into a 500mL three-necked flask, control the temperature to 110~120℃, and perform a negative pressure dehydration reaction for 6 hours . Cool to room temperature, add saturated salt water, stir, let stand and separate the organic phase, then add sodium hydroxide aqueous solution to wash until neutral. After combining the water phases, add potassium carbonate solution to wash until neutral, and use a small amount of petroleum ether to wash. Extract, combine the organic phases, dry and remove the solvent over anhydrous magnesium sulfate, and then distill out the isooctyl p-dimethylaminobenzoate (photoinitiator EHA) fraction under reduced pressure. The yield is 90%. The IR characterization results are consistent with the product. �The pre-distillation fraction is unreacted isooctyl alcohol, which can be reused. After the residual liquid in the kettle is concentrated for recovery of p-toluenesulfonic acid, a small amount of wastewater can be discharged in a conventional sewage treatment device to meet the standards.

Main reference materials

[1] Synthesis process of isooctyl p-dimethylaminobenzoate (photoinitiator EHA)

[2] Research on the synthesis of isooctyl p-dimethylaminobenzoate (photoinitiator EHA)

微信扫一扫打赏

微信扫一扫打赏