Background and overview[1][2]

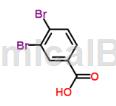

3,4-Dibromobenzoic acid is colorless crystal at room temperature, with a boiling point of 276°C. It is widely used as a pharmaceutical intermediate. In polymer plastic molding and processing, it is used as a special plasticizer, a compound or mixture of compounds added to polymer resins to provide flexibility and toughness. In recent years, people have paid attention to phthalate esters. Plasticizers These compounds are subject to rigorous examination for their potential negative effects on children’s health. Therefore, there was a need for phthalate-free plasticizers, and 3,4-dibromobenzoic acid was born.

The specific usage is as follows: the four-neck pot is equipped with a stirrer, thermocouple, Dean Stark trap device, and nitrogen flow. Add 1 mole of glycerol, 1.575 moles of 2-methylhexanoic acid, 1.575 moles of 3,4-dibromobenzoic acid (solid), and 1000 ppm zirconium acetate (catalyst) to the pot. The four-neck pot is then heated to reflux (approximately 200°C) and the water is removed from the pot through a Dean Stark trap. Gradually increase the temperature of the four-neck pan to approximately 220 -225°C over the course of approximately 2 hours. When the reaction is approximately two-thirds complete (approximately 4.5 hours), vacuum is applied to maintain good reflux. Near the end of the reaction (approximately 7 hours), a vacuum was applied to less than 10 torr to strip off excess 2-methylhexanoic acid and benzoic acid for recycling. The total reaction time is approximately 7 hours.

After the reaction is completed, cool the four-neck pot to 100°C, and carefully add 1.5 ml of 30% hydrogen peroxide and a certain amount of 50% (wt/wt) NaOH solution sufficient to raise the pH value of the mixture to approximately 13.0. Add to pot. Add 2.0ml of 30% by weight of hydrated hydroxyethylene diphosphate (available from Solutia, Inc. of St. Louis, Mo. As Dequest 2016) into the pot, and maintain the temperature of the four-necked pot at approximately 100°C. Continue The product was decolorized for 10 minutes and the zirconium acetate catalyst was removed. The product was washed three times with water at 80-85°C, and then the product was dehydrated and filtered.

20 grams of the above final product was mixed with 30 grams of PVC resin as a plasticizer, and the mixture was ground to provide a thin slice for plasticizer compatibility testing following the standard procedures of ASTM D-3219-97. A total of five plasticized PVC sheet test samples were examined and the average rating was less than 1.0.

3,4-Dibromobenzoic acid

Preparation [2]

Carry out methylnitration of toluene, take the para product, reduce it with Fe/HCl to obtain para-aminotoluene, and directly brominate this product to obtain 1-amino-2,5-dibromo-4-methylbenzene. Then react with NaNO2/HCl to obtain a diazonium salt, and then reduce it with H2PO3 to obtain 3,4-dibromotoluene. Finally, potassium permanganate is oxidized to obtain 3,4-dibromobenzoic acid.

Main reference materials

[1] Li Ji. (2012). Research on the performance of polylactic acid and triglyceride blend systems. (Doctoral dissertation, Tianjin University).

[2] Gao Zhuqing, Li Hongjin, & Gu Jinzhong. (2014). Synthesis and crystal structure of one-dimensional cadmium (II) and manganese (II) coordination polymer constructed with 3,5-dibromobenzoic acid and pyridine , fluorescence and magnetic properties. Journal of Inorganic Chemistry, 30(12), 2803-2810.

微信扫一扫打赏

微信扫一扫打赏