Background and overview[1]

3,4-Dichlorophenylmethylsulfonyl chloride can be used as a pharmaceutical and chemical synthesis intermediate. If 3,4-dichlorophenylmethylsulfonyl chloride is inhaled, please move the patient to fresh air; if there is skin contact, take off contaminated clothing, wash the skin thoroughly with soap and water, and seek medical treatment if you feel uncomfortable; If eye contact occurs, separate eyelids, rinse with running water or saline, and seek medical attention immediately; if ingested, rinse mouth immediately, do not induce vomiting, and seek medical attention immediately. 3,4-Dichlorophenylmethylsulfonyl chloride can be obtained by chlorosulfonation of 1,2-dichlorobenzene with chlorosulfonic acid.

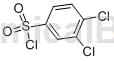

Structure

Preparation [1]

3,4-Dichlorophenylmethylsulfonyl chloride can be obtained by chlorosulfonation of 1,2-dichlorobenzene with chlorosulfonic acid. The apparatus consists of a three-neck flask with magnetic stir bar, equipped with a Friedrich condenser, a double adapter for the thermometer and a polytetrafluoroethylene (Teflon) tube for chlorine delivery, and a septum containing Teflon support Adapter for sampling. The top of the condenser is connected in series with an ice-cold empty trap (to condense any vapor that may not condense), a stirred water trap, and a stirred 10% aqueous KOH solution trap.

Adjust the chlorine flow to the desired level using a needle valve and measure the flow rate using a transducer. The unit was purged with nitrogen for 15 minutes and calculated amounts of the appropriate feedstock were introduced into the reactor under a gentle nitrogen purge. When no solvent is used, the starting material is melted by heating and maintained above the melting point. Turn on the condenser to condenser and bubble nitrogen through the material for 10 minutes. After the desired reaction temperature is reached, stop the nitrogen flow and bubble chlorine through the solution at an appropriate rate.

Typically, chlorine flow occurs intermittently at low rates because chlorine gas breakthrough is observed at higher throughput rates. After the reaction process, an aliquot was taken via syringe and quickly diluted with dichloromethane. For example, using a 65/35 wt% 3,4-dichlorophenylmethylsulfonyl chloride/3,4-DCPS mixture as raw material, preheat 17.1g of the mixture sample to 200°C and introduce chlorine gas at a rate of 0.02 mol/min. , after 3 hours, the reaction temperature was raised to 215°C and chlorine was passed through at the same rate for another 1 hour. GC analysis at this time showed that the reaction mixture was 84wt% 1,2,4-TCB, 11.8wt% 3,4- Dichlorophenylmethylsulfonyl chloride and 0.4 wt% 3,4-DCPS.

Main reference materials

[1] US5710355 Method of making chlorobenzenes

微信扫一扫打赏

微信扫一扫打赏