Background and overview[1]

1,2,4,5-Tetrachlorobenzene is soluble in alcohol, ether, benzene, chloroform and carbon disulfide, but insoluble in water. Used to make pesticides, fire retardants and other organic synthetic products.

Preparation[1]

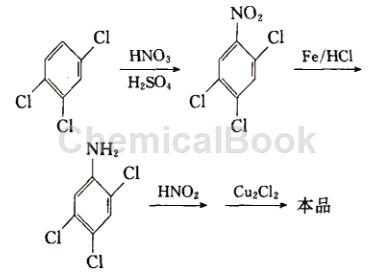

Method 1:

Method 2: Direct chlorination of benzene or chlorobenzene at high temperature under the catalysis of copper or iron;

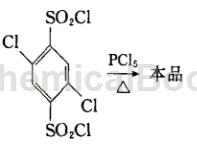

Method 3:

Detection method[2]

Ultrasound-assisted dispersive liquid-liquid microextraction-gas chromatography for detection of chlorobenzene in sludge:

Chlorobenzene compounds (CBs) are chlorobenzene o-dichlorobenzene, m-dichlorobenzene, p-dichlorobenzene, 1,2,3-trichlorobenzene, 1,2,4-trichlorobenzene, 1, 3,5-trichlorobenzene, 1,2,3,4-tetrachlorobenzene, 1,2,3,5-tetrachlorobenzene, 1,2,4,5-tetrachlorobenzene, pentachlorobenzene and hexachlorobenzene The general name of chlorobenzene is a colorless oily liquid. They are widely used in industry as intermediates for the synthesis of organic compounds such as dyes and pesticides, the manufacture of rubber additives, and solvents and heat transfer media. Chlorobenzene has been proven to be carcinogenic and can inhibit the central nervous system, irritate the eyes and upper respiratory tract, cause skin sclerosis and various blood diseases. Chlorobenzene is not easily degraded in the environment and has become one of the most common environmental pollutants in the world. It is potentially harmful to human health. The US Environmental Protection Agency and the European Union have listed it as a “blacklist” of priority pollutants and dangerous compounds for control.

CN201410276132.7 provides a method for the determination of chlorobenzene in sludge using ultrasonic-assisted dispersive liquid-liquid microextraction and gas chromatography/ECD detector. The method for detecting chlorobenzene in sludge using ultrasonic-assisted dispersive liquid-liquid microextraction-gas chromatography includes the following steps:

1) Standard solution preparation: m-dichlorobenzene, o-dichlorobenzene, 1,2,4-trichlorobenzene, 1,2,3-trichlorobenzene, 1,2,4,5-tetrachlorobenzene , 1,2,3,4-tetrachlorobenzene. Take 0.1000g of each of the six chlorobenzenes and dissolve them in acetone to prepare six 10 μg/ml stock solutions; 1,2,4-trichlorobenzene, 1,2,3 -Take 1.00ml of each of the 4 stock solutions of trichlorobenzene, 1,2,4,5-tetrachlorobenzene, and 1,2,3,4-tetrachlorobenzene, dilute to 10ml, and prepare 4 kinds of 1μg/ml Mix the standard solution; take 1.00ml of each of the two stock solutions of m-dichlorobenzene and o-dichlorobenzene, 1,2,4-trichlorobenzene, 1,2,3-trichlorobenzene, 1,2,4,5- Take 1.00ml of each of four 1μg/ml mixed standard solutions of tetrachlorobenzene and 1,2,3,4-tetrachlorobenzene, adjust the volume to 10ml, and prepare m-dichlorobenzene, o-dichlorobenzene 1μg/ml, 1, 6 kinds of 0.1μg/ml mixed standard solutions of 2,4-trichlorobenzene, 1,2,3-trichlorobenzene, 1,2,4,5-tetrachlorobenzene, and 1,2,3,4-tetrachlorobenzene ;

2) Ultrasonic-assisted extraction: Put 1.0g of sludge sample into a 50ml conical centrifuge tube with a screw cap, add 8.0ml of acetone, seal it, conduct ultrasonic extraction at 25°C for 20 minutes, centrifuge the extract, and pass the supernatant through 0.45μl microporous filter membrane, transferred into a 10ml conical centrifuge tube;

3) Dispersive liquid-liquid microextraction: Transfer 5.0ml of ultrapure water into a 10ml conical centrifuge tube with a screw cap, add 24.0μl of chlorobenzene to 1.0ml of acetone extraction solution, and quickly inject it with a 1ml micro-injection needle Mix 5.0ml of water to form an emulsion of acetone, chlorobenzene and water. Chlorobenzene is evenly dispersed in the water phase. Centrifuge at 4000r/min for 4 minutes. Chlorobenzene is deposited at the bottom of the centrifuge tube. Take 0.50μl of the deposited phase for gas chromatography. instrument analysis;

4) Gas chromatography analysis: The capillary gas chromatography column is a KB-Wax capillary column, its specifications are 30m×0.32mm, 0.25μm, the inlet temperature is 300°C, split injection, the injection volume is 0.50μl, load The gas is nitrogen, the flow rate is 30 ml/min, the initial temperature is 80°C, keep it for 1 min, raise it to 200°C at 20°C/min, keep it for 2 minutes, then raise it to 240°C at 40°C, keep it for 3 minutes to clean the column.

Compared with the existing technology, the present invention has obvious advantages: 1. This method is used to determine chlorobenzene compounds in sludge with high sensitivity and a detection limit of 0.001-0.2 μg/kg. 2. This method only requires a small amount of extraction agent (acetone 8ml, chlorobenzene 24μl). Compared with traditional detection methods such as Soxhlet extraction, it saves a large amount of organic solvents that are toxic to the human body. 3. The sample pretreatment time of this method is short (<30min), which saves analysis time compared with traditional detection methods, so it is suitable for the detection of large quantities of sludge samples.

Apply[3]

1,2,4,5-Tetrachlorobenzene is used to prepare indene-C60 double adduct:

C60 and its derivatives have become ideal electron acceptor materials in polymer bulk heterojunction thin film photovoltaic cells due to their high electron mobility and electron affinity. However, C60 has poor solubility in organic solvents. limits its application. In order to improve the solubility of C60 in organic solvents and then mix it with the donor polymer material in the liquid phase to produce a bulk heterojunction film, a common practice is to introduce substituents on its surface to increase its solubility in solvents. CN201110244851.7 provides a method for indene-C60 double adduct, which includes the following steps: add C60, indene and organic solvent into the reactor, heat and raise the temperature to 180~245°C under stirring, and react for 30~110 minutes. The solution was poured into methanol, and the precipitate was separated by centrifugation. The precipitate was made into a dry sample and separated by silica gel column chromatography to obtain the indene-C60 double adduct. The molar ratio of C60 and indene is 1:20 to 1:50, and the organic solvent is 1,2,4-trichlorobenzene, o-dichlorobenzene or 1,2,4,5-tetrachlorobenzene.

The beneficial effects of the present invention are as follows: The preparation method of the indene-C60 double adduct of the present invention has a higher reaction yield, and the yield can reach 45%, while the method in the comparative document has a reaction yield of 34 %. ;Indene-C60 double addition of the present inventionThe reaction time of the preparation method of the compound is shorter, and the reaction time is 30 minutes to achieve a yield of 36%, while the method in the comparison document has a reaction time of 12 hours and a yield of 34%.

Main reference materials

[1] Compound Dictionary

[2] CN201410276132.7 Ultrasound-assisted dispersive liquid-liquid microextraction-gas chromatography method for detecting chlorobenzene in sludge

[3] CN201110244851.7 Preparation method of indene-C60 double adduct

微信扫一扫打赏

微信扫一扫打赏