Background and overview[1]

4-Phenoxyphenylboronic acid is a white powdery crystal. It is a very versatile chemical intermediate and is widely used in the synthesis of medicines, dyes and other fine chemical products. In medicine, anti-cancer drugs can be prepared, such as ibrutinib, which is an oral first-of-its-kind drug called a Bruton’s tyrosine kinase (BTK) inhibitor that can interact with the active site of the target protein Btk. The cysteine residue (Cys-481) selectively covalently binds and irreversibly inhibits BTK, thereby effectively preventing tumor migration from B cells to lymphoid tissues adapted to the tumor growth environment.

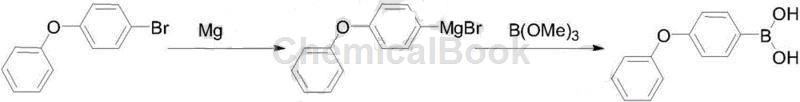

Preparation[1]

A method for preparing 4-phenoxyphenylboronic acid, using 4-bromodiphenyl ether as raw material, tetrahydrofuran as solvent, first reacting with magnesium flakes to prepare Grignard reagent, and the obtained Grignard reagent and trimethyl borate The ester reaction is followed by hydrochloric acid hydrolysis to obtain the crude product of 4-phenoxyphenylboronic acid, which is finally purified to obtain the finished product of 4-phenoxyphenylboronic acid. Specifically, it includes the following steps:

1) Under nitrogen protection, first put magnesium flakes and tetrahydrofuran into the reaction vessel, then add a small amount of iodine and 4-bromodiphenyl ether dropwise for initiation, and stir to control the dropping temperature at 10~70℃, then add dropwise the remaining mixed solution of 4-bromodiphenyl ether and tetrahydrofuran. After the dropwise addition is completed, the insulation reaction is carried out. After the raw material reaction is complete, the reaction is stopped to prepare the Grignard reagent; the feeding of 4-bromodiphenyl ether and magnesium flakes The molar ratio is 1:(1.0-1.2), preferably 1:1.1. The dropping temperature is 20~50℃, and the insulation reaction temperature is 20-50℃. The dropping temperature is preferably 30~35℃. The insulation reaction temperature is The temperature is 30~35℃.

2) Put the mixed solution of trimethyl borate and tetrahydrofuran into the reaction vessel, and under nitrogen protection conditions, cool the temperature to -60~-10°C and start dropping the Grignard reagent prepared above. After the dropwise addition is completed, the temperature is raised to 0 to 20°C for reaction. After the reaction is completed, hydrochloric acid with a mass concentration of 10% is added to the reaction system and stirred. Then it is left to stand and separated into layers. After extraction, the organic layers are combined and desolvated. , obtain crude 4-phenoxyphenylboronic acid; the dripping temperature of Grignard reagent is -60~20℃, preferably -40~-30℃; 4- The feeding molar ratio of brominated diphenyl ether and trimethyl borate is 1: (1.0-1.5), preferably 1:1.2.

3) Dissolve crude 4-phenoxyphenylboronic acid in toluene, and obtain pure 4-phenoxyphenylboronic acid after heating, cooling, crystallization and centrifugation.

Main reference materials

[1] CN201610304200.5 A preparation method of 4-phenoxyphenylboronic acid

微信扫一扫打赏

微信扫一扫打赏