Background and overview[1][2][3]

Dicyclohexyl phthalate (DCHP) is a plasticizer for polyvinyl chloride, acrylic resin, polystyrene and other resins. It is characterized by its moisture-proof effect. When used together with other plasticizers, it can make the product shrink and become denser. , to prevent water vapor from passing through and plasticizer evaporating. Plastic products containing DCHP have smooth surfaces and good hand feel. DCHP can also improve the fluidity of resin during thermal processing. In synthetic resin adhesives, it can improve its adhesion, oil resistance and durability. DCHP is used in nitrocellulose. Elements and some natural resins can be used to make moisture-proof coatings, etc. The dosage of DCHP generally accounts for 10% to 20% of the plasticizer dosage. If the dosage is too large, the hardness of the product will increase. As a high-end plasticizer, it is mainly used in moisture-proof cellophane coatings, paper moisture-proof coatings and high-end plastic products in China, and it mainly relies on imports.

Synthesis method[1][2]

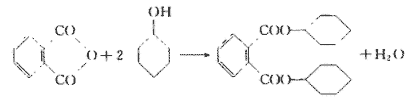

Synthetic path 1:

Using phthalic anhydride and cyclohexanol as raw materials, esterification reaction is carried out under normal pressure, and DCHP product is obtained through dealcoholization and crystallization. The reaction route is as follows.

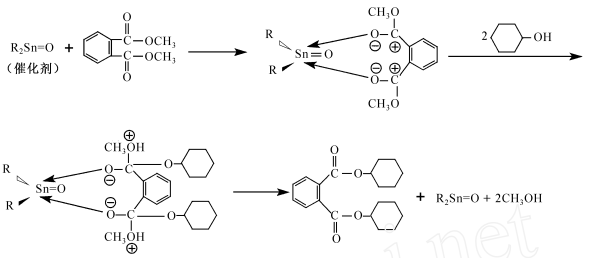

Synthesis path 2:

Add 32.6 mL (0.2 mol) of dimethyl phthalate, 46.8 mL (0.44 mol) of cyclohexanol and 1.4 g of organotin into a 250 mL three-necked flask, stir, and raise the temperature to 140 ℃ ~ 150 ℃, react at this temperature for 5 h, and methanol will continue to evaporate during the reaction process. Distill under reduced pressure to remove excess cyclohexanol and remaining methanol. Cool to obtain a crude product, which is then recrystallized with methanol to obtain a white solid powder, which is dicyclohexyl phthalate. The reaction route is shown in the figure below.

Application fields[3][4][5]

1. Preparation of plastic film

This plastic film contains the following weight components: 180 parts of PS resin, 4 parts of phosphite, 6 parts of dicyclohexyl phthalate, 3 parts of epoxidized soybean oil, and 7 parts of phosphite. , 7 parts of nitrile rubber, 1.8 parts of polycarbonate, 1.2 parts of microcrystalline paraffin, and 0.9 parts of calcium and zinc stabilizer. Pour the above components into the reaction kettle, stir for 50 minutes, heat to 130°C, pressurize 1.0MPa, react for 60 minutes to obtain a polymerization melt, add the polymerization melt to a parallel twin-screw granulator, and extrudate and granulate at 245°C. After drying, polyester chips are obtained. The polyester chips are melt-extruded at 245°C, cast into sheets and wound, biaxially stretched at 125°C, and cooled to form, to obtain anti-aging PS film for packaging.

2. Preparation of pigments

Weigh 100 parts of ethanol, 60 parts of ethylene glycol monoethyl ether, 40 parts of nitrocellulose, 25 parts of dicyclohexyl phthalate, 25 parts of methylcyclohexanone, and butyl acetate according to the mass fraction ratio. 5.5 parts, 6 parts n-butanol, 35 parts dewaxed shellac, 60 parts bentonite, 0.5 parts triethylenetetramine, stir and mix evenly in the reactor. The prepared product is used as a quick-drying pigment for woven fabrics. Its solid content is 38%, viscosity is 65s, pH=7, it will not deteriorate after 13 months of storage, its gloss is 86%, and its wear resistance is 180 times.

3. Preparation of solar cell conductive paste

The conductive paste containing dicyclohexyl phthalate is prepared from the following raw materials by weight: A material 50-52.4, B material 10-15, silane coupling agent KH5401-2, tributyl phosphate 0.5-1, silicone leveling agent 1-2, castor oil 0.3-0.5, sodium dodecyl sulfonate 0.2-0.4, dicyclohexyl phthalate 0.4-0.6, This conductive paste does not contain lead and fully complies with environmental protection requirements. It is used in the production of solar cells. It has strong adhesion on the surface of solar cells and high photoelectric conversion efficiency of the cells.

Detection technology[6]

Cyclodihexyl phthalate is a non-volatile phthalate ester (PAEs) with a high boiling point. The environmental pollution caused by PAEs has attracted widespread attention around the world. Among them, DMP (dimethyl ester), DEP (diethyl ester), DBP (dibutyl ester), BBP (butylbenyl ester), DNOP (di-n-octyl ester), DEHP (di-(2-ethylhexyl ester) ) esters), etc. have been listed as the preferred pollutants for testing by the US Environmental Protection Agency (EPA). The European Union has also identified six substances, including DBP, BBP, DEHP, DNOP, DINP (diisononyl ester), and DIDP (diisodecyl ester), as harmful substances to the human body and the environment, and stipulates that the total detected amount must be less than 0.1% . At the same time, PAEs plasticizers are also a type of “endocrine disruptor”, which can cause endocrine disorders in organisms (including humans), cause reproductive lesions, and can also cause cancer in animal liver tissue. There are 8 phthalates classified as “endocrine disruptors”, all of which are used as plasticizers. They are: DEHP, BBP, DBP, DCHP (dicyclohexyl ester), DEP, DNPP (dicyclohexyl ester). Pentyl ester), DHP (dihexyl ester), DPP (dipropyl ester).

1. Gas Chromatography

The GC method mainly uses HP-5 or DB-17HT fused silica capillary column to separate PAEs compounds. It has good separation for most compounds and can meet the requirements of analysis. However, for isomers with larger number of carbon atoms, The separation effect of compounds (such as diisononyl phthalate DINP, diisodecyl ester DIDP, etc.) is poor, the peak shapes overlap, and the detection limit is high, which affects accurate qualitative and quantitative analysis, and is not suitable for trace analysis. GC-MS has been widely used because it combines the dual functions of qualitative and quantitative methods. In particular, the use of selected ion mode (SIM) improves sensitivity and lowers detection limits.

2. Liquid chromatography

HPLC-UV methods mostly use C8 or C18 chromatographic columns, with methanol-water or acetonitrile-water as the mobile phase for reversed-phase gradient elution; electrospray ionization LC-MS technology can pass characteristic ions in the determination of PAEs Quantification of C6-C10 isomer mixtures solves the problem of low resolution and overlapping retention times between isomer groups when separating isomer mixtures by GC-MS method. However, when separating single-component compounds, The detection limit of GC-MS is lower than that of LC-MS.

Main reference materials

[1] Liu Leili, Hong Wangsun. Research on the synthesis process of dicyclohexyl phthalate[J]. Shandong Chemical Industry, 2003, 32(6): 6-7.

[2] Hu Yingxi, Liu Xia, Chen Chiyang. Synthesis of dicyclohexyl phthalate [D] by transesterification method. , 2005.

[3] Li Jia, an anti-aging PS film for packaging and its preparation method, CN 201510880462, application date 2015-12-03

[4] Chen Jintu, a new type of fast-drying pigment for woven fabrics, CN 201510225187, application date 2015-05-05

[5] Chen Long, Kuang Min, Ma Xiaoyan, a conductive silver aluminum paste containing dicyclohexyl phthalate, CN 201210527081, application date 2012-12-10

[6] Fang Liping, Niu Zengyuan, Cai Fa, et al. Progress in analytical methods for phthalate plasticizers[D]. , 2005.

微信扫一扫打赏

微信扫一扫打赏