Background and overview[1][3]

Boron trifluoride complex is a highly active catalyst that can be used in a variety of organic synthesis reactions, especially in the synthesis process of cephalosporin antibacterial drugs. Due to the introduction of boron trifluoride complex , shortening the reaction time of the original product, and greatly improving the yield of the original product. The catalytic effect of boron trifluoride acetonitrile complex is better than that of boron trifluoride etherate complex, so boron trifluoride acetonitrile complex has broad market prospects.

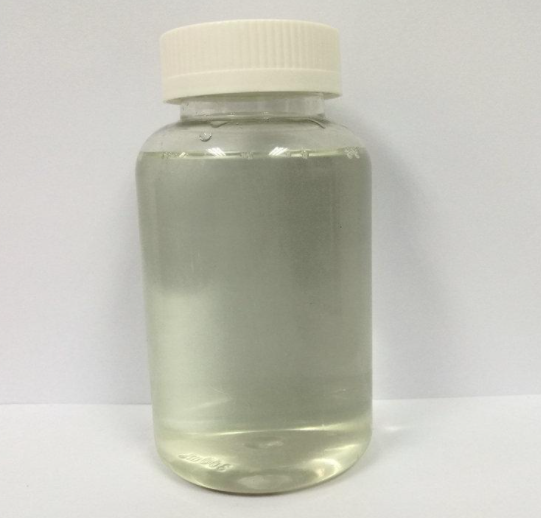

Boron trifluoride acetonitrile is a colorless or light yellow transparent liquid with a relative density of 0.9g/cm3. It has high solubility, is easily soluble in water, and is miscible in alcohol, ether, etc. A variety of organic solvents, mainly used as catalysts for organic reactions, cephalosporin antibiotics, important raw materials for preparing boron halides, elemental boron, borane, sodium borohydride and other borides, and basic raw materials for manufacturing boron hydrogen high-energy fuels and extracting isotopes. , can also be used as a curing agent for epoxy resin, generally produced through the reaction of fuming sulfuric acid, boric acid, hydrogen fluoride and acetonitrile.

Preparation[1-3]

Report 1,

Mix 1800kg sulfuric acid and 250kg boric acid, preheat the reaction tower. When the tower temperature reaches 250 degrees, use a metering pump to transport the mixed acid into the tower at a speed of 200Kg/h. At the same time, open the hydrogen fluoride cylinder and pass in hydrogen fluoride for reaction. The speed of feeding hydrogen fluoride is 25kg/h; filter and purify the boron trifluoride gas obtained through sulfuric acid in the purification container; preheat acetonitrile to 60 degrees for use, and start adding when the boron trifluoride gas is generated and reaches the complexing tank. Acetonitrile is complexed. During complexation, the complexing temperature must be maintained at 70°C, the specific gravity is greater than 0.855, the acetonitrile flow rate is controlled at 100/hour, and the complexed boron trifluoride acetonitrile complex flows directly into the finished product receiving tank. The content is 18%.

Report 2,

Boron trifluoride acetonitrile complex mainly reacts with hydrogen fluoride gas and boric acid under normal pressure and high temperature conditions to generate boron trifluoride, which is then complexed with acetonitrile to form the final product. The specific process flow is as follows: Mixed acid: Add boric acid to the stirring kettle and then pump in 20% oleum and stir for 2 hours. The whole process is cooled with indirect cooling water. After the two acids are fully mixed, they are pumped into the mixed acid storage tank. This process produces a small amount of waste gas SO3. Gas generation: Flow the mixed acid into the reaction tower from the upper port of the reaction tower, and add hydrogen fluoride gas into the reaction tower from the lower part of the reaction tower (use an air compressor to compress the hydrogen fluoride). The reaction tower is electrically heated to 200~250°C. The boron trifluoride generated by the reaction of boric acid and hydrogen fluoride enters the buffer tank from the upper part of the reaction tower. The waste sulfuric acid is cooled by indirect cooling water from the lower part of the tower body and then enters the waste acid storage tank. This process produces a certain amount of waste sulfuric acid and waste gas SO3. Filtration: Use a 40-mesh filter to filter the incompletely melted boric acid, and recover the filtered boric acid solid for reuse. Complexation: Pump measured acetonitrile into the complexing kettle to complex with boron trifluoride to form a product. The complexing kettle is indirectly cooled with water. The boron trifluoride content in the complex is about 20%.

Report 3,

The production process of boron trifluoride acetonitrile solid mixture, the process is as follows:

(1) Mixing: Mix boric acid solid and fuming sulfuric acid liquid evenly.

(2) Gas generation reaction: Preheat the gas generation reaction tower with a heater for 10 minutes, control the temperature between 200-300 degrees Celsius, and add boric acid solid and fuming sulfuric acid liquid mixed acid from the top to the gas generation reaction tower. In the reaction tower, the hydrogen fluoride gas is compressed and added from the bottom to the gas generating reaction tower. The fuming sulfuric acid, boric acid and hydrogen fluoride react chemically to generate boron trifluoride, sulfuric acid and water. The three gases generated during the reaction are Sulfur oxide waste gas is treated.

(3) Purification and filtration: Boron trifluoride, sulfuric acid and water are added to the purification and filtration tower. At the same time, sulfuric acid is added to the purification and filtration tower for purification. Waste sulfuric acid is recovered and sulfur trioxide waste gas is treated.

(4) Complexation reaction: After that, boron trifluoride is added to the complexation reaction tower, acetonitrile is added to the complexation reaction tower to perform the complexation reaction, and the reaction solution of the complexation reaction, the acetonitrile complex, is cooled and separated. Crystallize and obtain a small amount of boron trifluoride acetonitrile solid.

(5) Centrifugal purification: Centrifuge the reaction solution of the complexation reaction to obtain high-yield boron trifluoride acetonitrile solid.

(6) Collect finished products.

References

[1] [Chinese invention] CN201310296394.5 A method for preparing boron trifluoride acetonitrile

[2] [Chinese invention] CN201510806319.8 A production process of boron trifluoride acetonitrile complex

[3] [Chinese invention] CN201811038710.8 Production process of boron trifluoride acetonitrile solid mixture

微信扫一扫打赏

微信扫一扫打赏