This article synthesizes an anti-adsorbent for concrete through the design of its molecular structure, and discusses the performance of the anti-adsorbent for concrete under the conditions of aggregates with different mud and stone powder contents. Anti-adsorption properties and application performance in concrete.

Test

1. Test materials and instruments

Monomer A, analytically pure; Monomer B, analytically pure; Initiator, analytically pure; Chain transfer agent, analytically pure; Reducing agent, analytically pure; Alkali solution; Deionized water.

Cement, P·O 42.5R grade cement: Conch Cement Co., Ltd. Yingde Cement Plant; fly ash: Taishan Power Plant; ore powder S95: Shougang Ore powder; fine aggregate: river sand 1, (fineness modulus 2.6, mud content 5.9%), river sand 2, (fineness modulus 2.7, mud content 2%); quarry environmentally friendly recycled stone powder (fine Fineness modulus 3.2, mud content 6.9%), environmentally friendly recycled ground aggregate (fineness modulus 3.0, mud content 7.3%); coarse aggregate, Guangxi limestone (5-31.5mm continuous gradation, mud content 3%); polycarboxylate water-reducing agent, Guangdong Liuhe New Building Materials Co., Ltd. (LH-6BN), water reduction rate of more than 20%; anti-adsorption agent for concrete, Guangdong Liuhe New Building Materials Co., Ltd.

JJ-1 electric mixer; HL-2B constant flow pump; DK-98-Ⅱ water bath, electronic balance; four-necked flask; NJ-160 cement Slurry mixer; laboratory concrete mixer; pressure testing machine.

2. Synthesis process

In a four-necked flask with a stirrer and thermometer Add a certain amount of deionized water and monomer B, and heat the flask in a water bath. After the temperature rises to a certain temperature and monomer B is completely dissolved, add the initiator and stir. Then start using a constant flow pump to control the flow rate and add monomer A dropwise. In addition, the mixed solution of reducing agent and chain transfer agent is added dropwise. Both solutions are added dropwise within a certain period of time, and then continue to stir and keep warm for 2 hours. After the reaction is completed, add liquid alkali and adjust the pH value to 7±1 to obtain the anti-adsorption agent for concrete.

3. Cement mortar fluidity test

4. Concrete test

Test results and discussion

1 Anti-adsorbent for concrete, in fine aggregates with different adsorption properties, Effect of polycarboxylate superplasticizer on the dispersion of cement mortar.

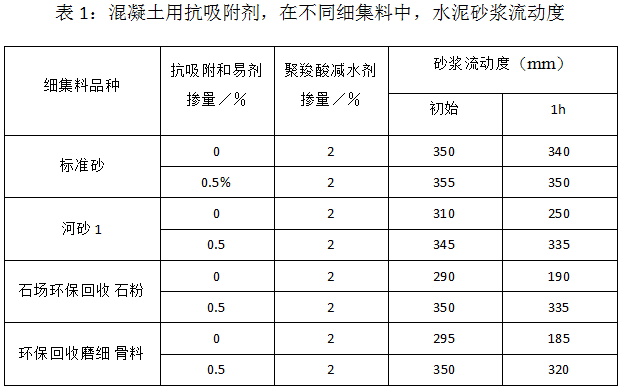

When the polycarboxylate water-reducing agent encounters adsorbent materials, the adaptability of the water-reducing agent becomes very poor and very sensitive. This article mainly studies the different When fine aggregate replaces standard sand, the effect of anti-adsorbent for concrete on the adaptability of water-reducing agent is analyzed. The fine aggregates are selected from stone quarry environmentally friendly recycled stone powder, environmentally friendly recycled ground aggregate, river sand 1, and standard sand. The experimental results are shown in Table 1.

As can be seen from Table 1, when using adsorbent aggregates, reduce The dispersion of the water agent has a great influence. As shown in the figure, when using standard sand to conduct the mortar dispersion test, the mortar has good fluidity and the loss of fluidity over time is small, indicating that there is no problem with the water-reducing agent used. After adding the anti-adsorbent for concrete, it has little effect on the mortar fluidity of standard sand, indicating that the anti-adsorbent for concrete will not affect the mortar performance of normal materials.

When using river sand 1, because the mud content in river sand 1 is large, the adsorption capacity of the mud content to the water-reducing agent is large, and the stone On-site recycled stone powder and recycled ground stone powder, in addition to the adsorption of water-reducing agent by the mud content, the porosity characteristics of the recycled materials make the recycled aggregates more adsorbent, and the mortar flow performance is even less ideal. The three adsorbent materials After adding anti-adsorbent for concrete, the fluidity and adaptability of the mortar are significantly improved.

Concrete test results

1 Anti-adsorbent for concrete, the use of different adsorption fines Effects of aggregate concrete.

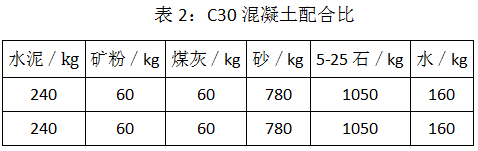

In the actual use process of polycarboxylate water-reducing agent, due to the use of fine aggregates containing mud, powder and porous structure, it will cause The adsorption of water agent is so serious that no matter how much amount is added, the concrete cannot be “opened”, and the concrete has no fluidity and workability. The biggest feature of the new anti-adsorption agent for concrete is that it can solve the problem of adsorption of polycarboxylate water-reducing agent during the concrete production process, improve the adaptability of the water-reducing agent and the quality stability of the factory concrete. This article mainly studies the changes in concrete under different adsorbent materials. C30 concrete was used in the test. The mix ratio of concrete is shown in Table 2.

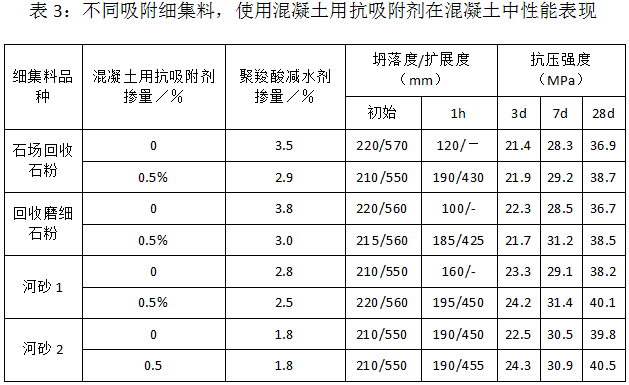

Select three fine aggregates with different degrees of adsorption to verify the anti-adsorption of concrete The degree of improvement of the agent on the working performance of concrete, and the impact on the strength of concrete in the later period. The fine aggregate is environmentally friendly recycled stone powder from the quarry, river sand 1, river sand 2, environmentally friendly recycled ground stone powder, concrete propertiesAs shown in Table 3.

As can be seen from Table 3, the mud content in concrete aggregate is relatively high In the case of strong adsorption, the concrete using the new anti-adsorbent for concrete has obviously good adaptability and retention, and the anti-adsorbent for concrete not only has no effect on the strength of the concrete, but from the experimental results, This modifier has a certain positive effect on the strength growth of concrete. In addition, the cohesion and workability of four different aggregates using anti-adsorbent for concrete are better than those without anti-adsorbent for concrete, which greatly improves the concrete construction performance of environmentally friendly recycled materials, and the effect is very obvious .

Conclusion

By using new anti-adsorbent for concrete, the fluidity of cement mortar and concrete From the study of application performance, the following conclusions can be drawn:

(1) Anti-adsorbent for concrete has strong anti-adsorption ability for different adsorbent materials, making it easy to leave the factory Concrete has good workability and stability.

(2) Anti-adsorbent for concrete greatly improves the workability of environmentally friendly recycled aggregates, and while improving the workability, it also affects the strength of concrete. The growth has no impact and is slightly enhanced.

(3) Anti-adsorption agents for concrete, when there are adsorbent aggregates, have anti-adsorption properties that affect the workability and durability of concrete. The loss improvement is very obvious. When there is no adsorbent aggregate, it has no impact on the workability of concrete. It avoids the uncontrollability in the concrete production process due to the instability of adsorbent aggregate, thus making the concrete production Quality levels off.

<img src="/upfile/202304/2023041334528065.jpg"/

微信扫一扫打赏

微信扫一扫打赏