Background and overview[1][2]

P-isobutylstyrene, also called 4-p-isobutylstyrene, is an impurity in the synthesis of ibuprofen. Alkenes are a very important type of synthetic intermediates in organic chemistry. Various other groups can be easily introduced through the reaction of olefins, such as the preparation of halogenated compounds through addition reactions and the preparation of cyclic compounds through D-A reactions; on the other hand, alkenes are also Various coupling reactions can occur through Heck reaction, Suzuki reaction, etc. It is widely used in the field of synthesis.

Preparation[1]

The method is the same as Example 1, and the yield is shown in Figure 1.

Using nuclear magnetic resonance to analyze 4-isobutylstyrene, the results were obtained: 1H NMR (400MHz, CDCl3) δ7.32 (d, J =8.1Hz, 2H), 7.10 (d, J = 8.0Hz, 2H), 6.69 (dd, J = 17.6, 10.9Hz, 1H), 5.70 (dd, J = 17.6, 1.0Hz, 1H), 5.18 (dd , J=10.9, 1.0Hz, 1H), 2.45 (d, J=7.2Hz, 2H), 1.91-1.79 (m, 1H), 0.90 (d, J=6.6Hz, 6H).

13C NMR (101MHz, CDCl3) δ141.5, 136.8, 135.0, 129.3, 126.0, 112.8, 45.2, 30.2, 22.4.

Example 1:

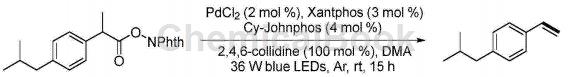

Add photocatalyst palladium chloride (2mol%, 0.7mg), 4,5- Bisdiphenylphosphine-9,9-dimethylxanthene (L1) (3mol%, 3.5mg), 2-(dicyclohexylphosphino)biphenyl (L2) (4mol%, 2.8mg) and active Aliphatic NHPI ester (0.2mmol, 80.2mg). Completely replace the air in the tube with argon three times, and then add 2,4,6-trimethylpyridine (0.2 mmol, 24.2 mg) and 2 mL of N, N-dimethylacetamide (DMA) under an argon atmosphere. The reaction system was continuously stirred at room temperature for 15 hours under the irradiation of a 36W blue LED lamp (using an IKA magnetic stirrer, RCT basic type, stirring speed 500 rpm). After the reaction is completed, the reaction is quenched with H2O, and the reaction solution is extracted with ethyl acetate (3*10mL), and the combined organic phase is concentrated by rotary evaporation (Swiss Buchi Co., Ltd., BUCHI rotary evaporator R-3) . The concentrated residue was passed through chromatography column (Beijing Xinwei Glass Instrument Co., Ltd., C383040C chromatography column with sand plate storage ball, 35/20, effective length: 500mm) to obtain the product.

Apply[2]

Adsorption resin is a polymer sphere with an internal cross-network structure and has been widely used in the field of adsorption and separation. CN200810022478.9 uses one of p-methylstyrene, 4-tert-butylstyrene and 4-iso-butylstyrene mixed with styrene as the monomer, and divinylbenzene as the cross-linking agent to synthesize a A series of hydrophobic and highly microporous cross-linked polystyrene adsorbent resins. In the process of treating waste gas containing volatile organic compounds, the adsorption performance of the adsorbent is minimally affected by moisture and has good application prospects.

The technical solution of the present invention is as follows:

A hydrophobic and highly microporous adsorption resin, which is composed of (1) styrene, (2) p-methylstyrene, 4-tert-butylstyrene or 4-isobutylstyrene (3) A hydrophobic, highly microporous adsorption resin made of divinylbenzene polymerized and cross-linked. The mass ratio of monomers in each component is:

Styrene 30-70 parts

(2) 20-60 parts of p-toluene, 4-tert-butylstyrene or 4-isobutylstyrene

(3)Divinylbenzene 2.5-10 parts

The specific surface area of the resin is ≥820m2/g; the pore volume is ≥0.5cm3/g; the microporosity is ≥55%; the average pore diameter is concentrated at 1.5-2.2nm, and the contact angle between the resin and water is 130-149°.

A method for preparing the above-mentioned hydrophobic highly microporous adsorption resin, which consists of the following steps:

(1) Preparation of low cross-linking degree polymer resin (synthesis of white balls)

(A)will

(1) p-methylstyrene, 4-tert-butylstyrene or 4-isobutylstyrene 20-40%

(2) Styrene 20-50%

(3)Divinylbenzene 2-10%

(4) Toluene or No. 200 solvent oil 10-50%

(5)Initiator 0.5-1%

Mix thoroughly to obtain oil phase A,

(B) Prepare an aqueous solution of dispersant I 0.5-5% (mass fraction, the same below), magnesium sulfate 1-10%, sodium carbonate 0.5-1% and sodium chloride 5-20% to obtain aqueous phase B , dispersant I is gelatin or hydroxyethyl fiberSu,

(C) Add the prepared oil phase A to the water phase B under stirring, add stabilizer C, stir and disperse the oil phase A into oil beads of the required size, add 0.1- 0.1- of the mass of the water phase B 1% dispersant II, temperature-raising reaction, dispersant II is a sodium lignosulfonate aqueous solution with a mass concentration of 5-20%. The components of stabilizer C are: a methylene blue aqueous solution with a mass fraction of 1-10%,

After the reaction (D) is completed, the monomers are polymerized into balls, filtered, washed several times with hydrochloric acid, hot water, and cold water with a mass concentration of 0.5-2%, and dried to obtain polymerized white balls a.

(2) Chloromethylation of hydrophobic low-crosslinking polymer resin under Lewis acid catalyst

(E) Swell the polymerized white ball a obtained in the above step (D) with 3-8 times its mass of methyl chloride at 20-30°C for 2-5 hours, add an appropriate amount of Lewis acid catalyst D in three times, and raise the temperature Stir and react at 30-40°C for 6-24 hours to obtain chloromethylated cross-linked polystyrene resin chlorine balls b.

Lewis catalyst D can be: anhydrous zinc chloride, anhydrous ferric chloride, anhydrous aluminum chloride or anhydrous tin chloride,

(3) Post-crosslinking reaction of chloromethylated low-crosslinked polymer resin catalyzed by Lewis acid catalyst D

(F) Swell the chlorine sphere b obtained in step (E) with an inert solvent G 3-8 times the mass of the chlorine sphere b at 20-30°C for 2-4 hours. The inert solvent G is nitrobenzene or 1,2-Dichloroethane, (G) Take 5-30% Lewis acid catalyst D of chlorine sphere b mass, divide it equally into 3-5 parts, add one part every half hour, and heat it up to 70-95℃, react for 6-12 hours, then raise the temperature to 100-120℃, react for 4-8 hours, filter, wash with cold water several times, and dry.

(H) Extract the resin obtained in step (G) with a low boiling point organic solvent. The preferred low-boiling point solvent is ethanol or acetone. Generally, the hydrophobic microporous adsorption resin with excellent properties and appearance can be obtained by extraction with a Soxhlet extractor for 4-8 hours and screening.

The hydrophobic and highly microporous adsorption resin of the present invention has obvious adsorption and separation effects on non-polar or weakly polar volatile organic waste gases, and the adsorption process is minimally affected by moisture, is easy to regenerate, and can be effectively used For the treatment and recycling of related organic waste gases.

Main reference materials

[1] CN201810341241.0 Preparation method of olefins and method of synthesizing ChondriamideA and ChondriamideC

[2] CN200810022478.9 A hydrophobic highly microporous adsorption resin and its preparation method and use

微信扫一扫打赏

微信扫一扫打赏