Background and overview[1]

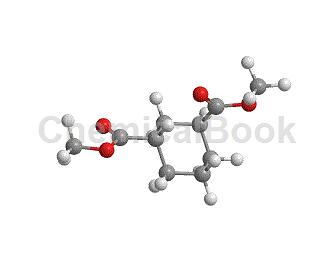

1,3-Dimethyl cyclohexanate can be used as a pharmaceutical synthesis intermediate and an organic synthesis intermediate. It is mainly used in laboratory research and development processes and chemical and pharmaceutical synthesis processes. If 1,3-cyclohexanedioic acid dimethyl ester is inhaled, please move the patient to fresh air; if there is skin contact, take off contaminated clothing, rinse the skin thoroughly with soap and water, and seek medical treatment if you feel uncomfortable; If eye contact occurs, separate eyelids, rinse with running water or saline, and seek medical attention immediately; if ingested, rinse mouth immediately, do not induce vomiting, and seek medical attention immediately.

Preparation[1]

The preparation of 1,3-cyclohexanedioic acid dimethyl ester is as follows: Dissolve cyclohexane-1,3-dicarboxylic acid (8.6g, 50.0mmol) in 60mL methanol, and add trimethylchlorosilane at room temperature (1.63g, 15.0mmol), react for 72 hours, add 100mL dichloromethane, wash twice with saturated sodium bicarbonate aqueous solution, dry, spin dry the solvent, and obtain 1,3-cyclohexanedioic acid dimethyl ester as a colorless oil.

Apply[1]

1,3-Cyclohexanedioic acid dimethyl ester can be used as a pharmaceutical synthesis intermediate. For example, prepare 3-(hydroxymethyl)cyclohexylcarboxylic acid methyl ester: Dissolve 1,3-cyclohexanedioic acid dimethyl ester in 50 mL methanol, add 50 mL 1N sodium hydroxide aqueous solution, stir in an ice-water bath for 1 hour, and then move to room temperature. React for 2 hours, spin dry the methanol, wash the water phase once with ethyl acetate, adjust the water phase to pH=2-3 with concentrated hydrochloric acid, extract three times with ethyl acetate, combine the organic phases, dry and concentrate to obtain a white solid 3- (Methoxycarbonyl) cyclohexylcarboxylic acid 6.3g, the total yield of the two steps is 67.7%. In the dry reaction bottle, add 3-(methoxycarbonyl)cyclohexylcarboxylic acid (6.3g, 33.9mmol), add 100mL anhydrous tetrahydrofuran, and slowly add borane dimethyl sulfide tetrahydrofuran solution (2M) dropwise at -78°C. , 18.65mL, 37.3mmol), slowly rise to room temperature and continue the reaction for 24 hours. Add saturated aqueous ammonium chloride solution, extract three times with ethyl acetate, dry, concentrate, and pass through a silica gel column (100% petroleum ether – petroleum ether: ethyl acetate = 3:1) to obtain 3.2g of 3-(hydroxymethyl)cyclohexylcarboxylic acid methyl ester as a colorless oil, with a yield of 54.9%.

Main reference materials

[1] CN201410493612.9FXR agonist

微信扫一扫打赏

微信扫一扫打赏