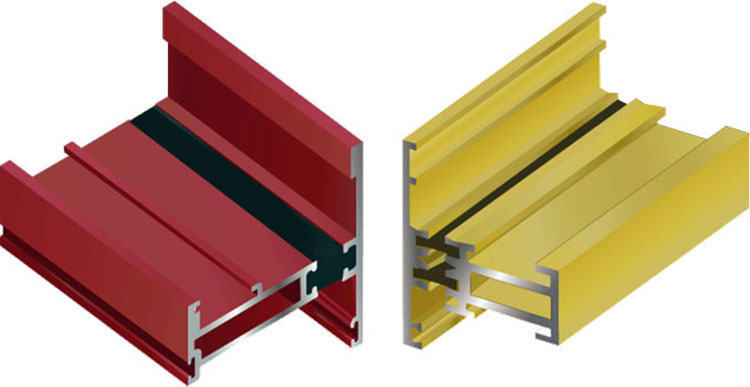

Thermal insulation glue strips are worn strips The core component of the heat-insulating profile is the “broken bridge” on the heat transfer path in the aluminum profile, which reduces the heat transfer in the aluminum profile. It is also the core component of the heat-insulating profile. The structural connectors of the aluminum profiles on both sides make the three parts of the insulating profile become a whole and jointly bear the load. It is different from the rubber strip, which is made into a new composite material by mechanical rolling. It cannot be replaced individually. It can only be replaced with the entire profile.

Internal glass fiber structure of the insulation strip

The inherent structural quality of the insulation strip is the principle guarantee for the strength and stability of the profile.

The reason for choosing glass fiber reinforcement: Because nylon66 has creep properties. That is, under the action of a certain external stress, the deformation increases with time. In order to suppress the creep of nylon 66, experiments have proven that nylon 66 reinforced with glass fiber is equivalent to aluminum alloy in terms of strength, rigidity and heat deformation temperature. Avoiding thermal insulation caused by thermal expansion and contractionglueDanger of strips falling off from between profiles.

Glass fiber arrangement: The glass fibers are arranged horizontally+vertically in the insulation strip, that’s it Increasing the longitudinal tensile strength can also increase the transverse tensile strength. However, in order to achieve the horizontal and vertical arrangement of glass fiber, it is necessary to have suitable molds, propelling screws and special hexagonal clamps, and these technologies are currently only mastered by Germany.

Title of this article: Overview of broken bridge aluminum insulation strips

Source of this article: http://www.wellgo.com.cn/newb/information_2445. shtml

微信扫一扫打赏

微信扫一扫打赏