KRAIBURG TPE®

Launched thermoplastic elastomer (TPE) with adjustable proportion of recycled raw materials. With the introduction of these new compounds, as a global TPE manufacturer we are adding to a range of product lines made from renewable raw materials, including sustainable TPE solutions Thermoplastic R

(THERMOLAST® R) series. Bio-based TPE has a lower product carbon footprint compared to existing alternatives that do not contain renewable raw materials.

Waldkreiburg, October 17, 2023 –

Sustainability is a key factor in all design phases. This concept must be taken into account at the beginning of the project to ensure that it contributes to the long-term success of the project. KRAIBURG TPE®

of customers have chosen to use sustainable compounds that contain a portion of post-industrial or post-consumer recyclates, particularly in everyday consumer goods and automotive applications. From the early use of fossil resources as base materials to later renewable materials, KRAIBURG TPE

We hope to improve our company’s solutions for sustainable development through the transformation of bio-based thermoplastic elastomers (TPE).

KRAIBURG TPE®

When evaluating new raw materials for bio-based TPE, the focus is on materials that are not used in food production. These raw materials include agricultural by-products or waste materials from food production (waste that cannot be used in food even after further processing). We will conduct a rigorous assessment of raw material sources to meet the stringent requirements set by our company, and work closely with suppliers to ensure that bio-based and recycled raw materials reach a level equivalent to traditional base polymers.

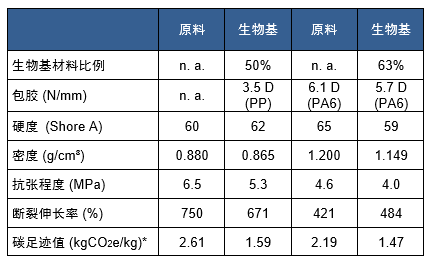

Compared with TPE made from fossil fuel-based materials, bio-based TPE can reduce the product carbon footprint (PCF) by up to 50%. Carbon footprint refers to the total amount of greenhouse gas emissions, specifically carbon dioxide (CO2), associated with the production, use and disposal of a specific product or service. Understanding the carbon footprint can help end consumers and processing companies make informed decisions when selecting materials to produce and promote more sustainable products. Bio-based TPE uses renewable raw materials in production, KRAIBURG TPE®

Actively help customers achieve their sustainable development goals.

Bio-based TPE has similar smell, feel, grip and encapsulation properties to fossil fuel-based TPE. This new product features 30 to 85 Shore

The hardness range is A and can be laminated with PP, ABS/PC and PA. The biological content of individual compounds exceeds 60% and can be encapsulated and colored with PP and polar materials. The material has been thoroughly tested for injection molding and extrusion, and its processing properties are comparable to fossil fuel-based TPEs.

* According to DIN EN ISO 14067 and based on DIN EN ISO 14040/14044 and GHG

The principle of Protocol is evaluated from production to delivery. These values include biological uptake, transport, packaging and mixing processes.

“By using bio-based TPE, we are filling a gap in our product portfolio and moving towards a more sustainable TPE. Our bio-based TPE provides a more sustainable solution that maintains consistent levels of At the same time, the carbon footprint of the product is reduced. We look forward to projects that will enable us to transition from fossil fuel-based materials to more sustainable raw materials,” KRAIBURG TPE

sums up Tobias Brückner, Senior Development Project Manager at .

Bio-based TPE is currently only manufactured in Germany, and KRAIBURG TPE will provide global supply services as soon as possible.

Figure 1: Bio-based TPE has a lower product carbon footprint compared to compounds not based on renewable raw materials. (Source: KRAIBURG TPE)

Figure 2: Tobias Brückner, Development Project Manager KRAIBURG TPE (Source: KRAIBURG TPE)

About KRAIBURG TPE

KRAIBURG TPE (www.kraiburg-tpe.cn) is a manufacturer of custom thermoplastic elastomers with a global footprint. KRAIBURG TPE founded in 2001

In 2007, it was an independent business unit of the Kaibo Group and has become the most competitive industry leader in the field of TPE compounds. KRAIBURG TPE aims to provide customers with safe, reliable and sustainable products. KRAIBURG TPE has more than 680

employees around the world, with production bases in Germany, the United States and Malaysia, committed to providing a wide range of products to the automotive, industrial, consumer goods and highly regulated medical fields. Its mature product line – Thermoplastic

(THERMOLAST®), COPEC®, HIPEX® and For Tec E®

, using injection molding or extrusion processes, brings superior processing and product design advantages to manufacturers in a variety of industries. KRAIBURG TPE®

With excellent innovation capabilities and global customer orientation, we are able to provide customers with customized product solutions and reliable supporting services. The company’s headquarters in Germany is ISO 50001 certified, and all sites worldwide are ISO

9001 and ISO 14001 certificationcertificate.

微信扫一扫打赏

微信扫一扫打赏