Polyurethane Frequently asked questions about electronic potting glue

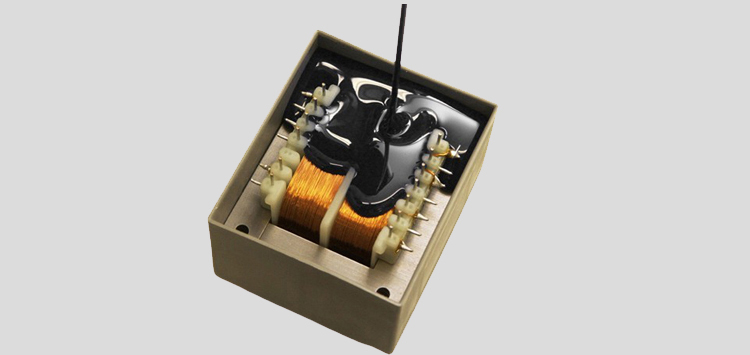

Polyurethane potting glue is also known asPU potting glue,Usually composed of polyol (main agent) and isocyanineacidester (cured Agent) composition,Use diol or diamine as chain extender,pass Gradually aggregated. It is characterized by low hardness, moderate strength, good elasticity, water resistance, mold-proof, shock-proof, excellent electrical insulation and flame retardancy, No corrosion to electrical components,For steel, aluminum, copper, tin and other metals,and rubber, plastic, wood and other materials have good adhesion, can also protect the installed and debugged electronic components and circuits from vibrations , corrosion, moisture and dust, etc. With the wide application of polyurethane products in the electronics industry,However, some problems gradually appeared during the application process due to unscientific use,The editor of Weigu will take you to learn more about these problems and their causes.

1. Complete or partial non-curing phenomenon

1. Product mixing ratio Misalignment: The ratio is not proportioned according to the technical specifications.�合;Not fully stirred evenly when filling glue manually; when filling glue with equipment,A/B The glue output debugging is not in place.

2. Failure of the curing agent component: During storage or use, the product was not sealed or removed frequently. If used, the curing agent component will become ineffective due to moisture.

Solution:

1. Calibrate the electronic scale used to ensure the accuracy of the electronic scale;

2. When manually filling glue, the selected mixing container should be flat and regular to facilitate mixing, and the mixer used should be even at the bottom and side walls of the container. Stir until in place, stirring for more than 1 minute;

3. When debugging the equipment, weigh components A and B respectively. The glue output is adjusted to adjust the air pressure to meet the specified ratio;

4. The curing agent component is due to the active ingredients in this component Chemical reactions occur when exposed to moisture and are consumed,During the storage process, it should be stored in a dry environment and kept in a dry environment before removal. Seal immediately after use,If used frequently,The curing agent components can be packaged into small packages suitable for one-time use.

2. There are bubbles after curing

1. The selected product has poor foaming performance, and air will be trapped in the product during the mixing process, and it will not Carry out vacuum degassing;

2. Before use, the product was not stirred evenly, resulting in , excess polyol, resulting in bubbles produced by the reaction;

3. The surface of the potting device is affected by moisture. There is a large amount of water vapor. After the glue is poured, the isocyanate in the product reacts with water to produce bubbles.

Solution:

1. Choose a product with good foaming performance Products;

2. When mixing, stir clockwise and in one direction. Mix After uniformity, vacuum degassing treatment is performed;

3. Stir component A before use Evenly to avoid stratification of glue;

4. Perform on the devices that need to be filled Drying and dehumidification treatment.

3. The hardness or color is unstable after curing

1. The product is stored for too long, and the polyol component appears to be separated. The phenomenon of layering is caused by insufficient mixing before use, resulting in uneven distribution of fillers and unstable hardness after curing;

2. Due to the high density of the color paste, it will settle during storage. It is not fully stirred evenly before use, resulting in different shades of color after curing.

Solution Solution:

This situation can be avoided by stirring the polyol component evenly before use.

le=”margin-bottom:15px;text-align:left;background:rgb(255,255,255)”>1. Choose products with good foaming properties;

2. When mixing, stir clockwise and in one direction. After mixing evenly, perform vacuum degassing;

3. Stir component A evenly before use to avoid stratification of the glue;

4. Dry and dehumidify the devices to be filled.

3. The hardness or color is unstable after curing

1. The product is stored for too long, and the polyol component appears to be separated. The phenomenon of layering is caused by insufficient mixing before use, resulting in uneven distribution of fillers and unstable hardness after curing;

2. Due to the high density of the color paste, it will settle during storage. It is not fully stirred evenly before use, resulting in different shades of color after curing.

Solution Solution:

This situation can be avoided by stirring the polyol component evenly before use.

微信扫一扫打赏

微信扫一扫打赏