On August 4, the Department of Hazardous Chemical Supervision of the Ministry of Emergency Management publicly solicited opinions on the “Catalogue of Elimination of Outdated Hazardous Chemicals Safety Production Technology and Equipment (Second Batch)” (Draft for Comment).

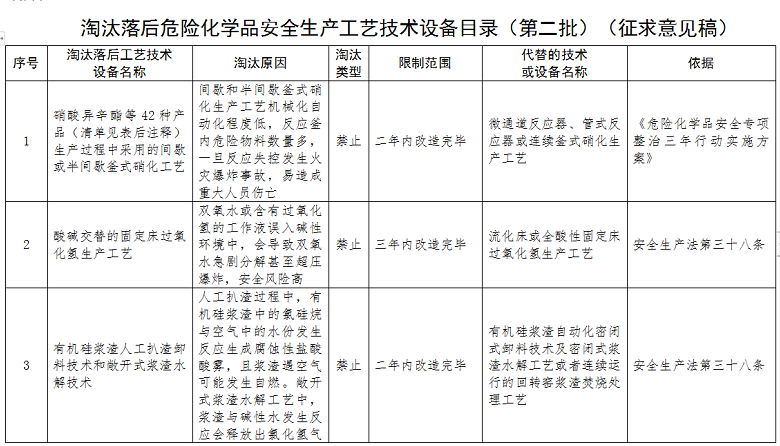

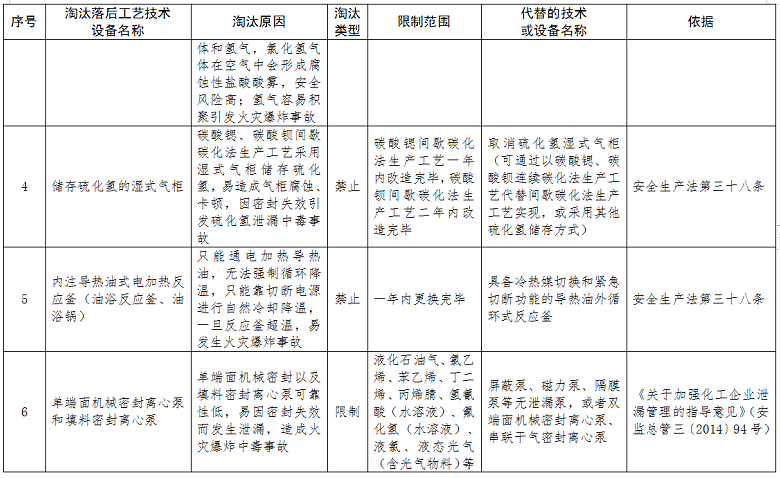

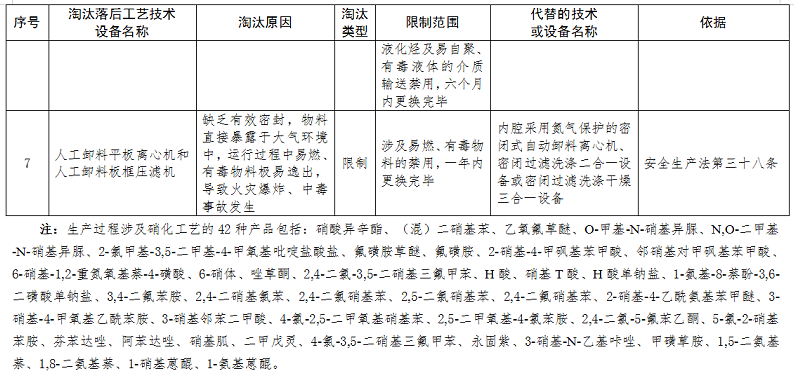

The “Catalogue” lists the second batch of elimination of 3 types of backward technology and 4 types of backward equipment, including 5 types of prohibited types and 2 types of restricted types, and clarifies the scope of restrictions, time limit for transformation and replacement suggestions.

The elimination of outdated technologies includes 3 types: the batch or semi-batch tank-type nitration process used in the production process of 42 products such as isooctyl nitrate, which is set as a prohibited category and requires the transformation to be completed within two years; fixed-bed hydrogen peroxide with alternating acid and alkali The production process is set as a prohibited category, and the transformation is required to be completed within three years; the artificial slag removal and unloading technology of organic silicon pulp and residue and the open type pulp and residue hydrolysis technology are set as a prohibited category, and the transformation is required to be completed within two years.

Elimination of outdated equipment includes 4 types: wet-type gas cabinets for storing hydrogen sulfide, which are set as prohibited, requiring the transformation of strontium carbonate intermittent carbonization production process within one year, barium carbonate intermittent carbonization production process within two years; internal injection of heat transfer oil Type electric heating reactors (oil bath reactors, oil bath pots), set as prohibited, and require replacement within one year; single-end mechanical seal centrifugal pumps and packing seal centrifugal pumps, set as restricted, liquefied petroleum gas, vinyl chloride , styrene, butadiene, acrylonitrile, hydrocyanic acid (aqueous solution), hydrogen fluoride (aqueous solution), liquid chlorine, liquid phosgene (materials containing phosgene) and other liquefied hydrocarbons and media that are easy to self-polymerize and toxic liquids are prohibited. It is required to complete the replacement within six months; the manual unloading plate centrifuge and the manual unloading plate-and-frame filter press are set as restricted categories, and equipment involving flammable and toxic materials is prohibited, and the replacement is completed within one year.

In recent years, typical accidents in some industries such as nitrification and hydrogen peroxide production have exposed some technological and equipment outdated technologies, low intrinsic safety levels, and high safety risks. At the same time, with the continuous development and application of new safety processes, new technologies, and new equipment for hazardous chemicals, safer, mature, and reliable alternative technologies or equipment have been developed, and the conditions for eliminating backwardness have been met.

Article 38 of the “Safety Production Law” clearly states that the state implements an elimination system for processes and equipment that seriously endanger production safety, and production and business units shall not use processes and equipment that should be eliminated and endanger production safety.

In October 2020, the Ministry of Emergency Management issued the “Catalogue of Elimination of Outdated Hazardous Chemicals Safety Production Technology and Equipment (First Batch)”, which listed 4 types of obsolete technologies and 8 types of equipment, including 6 prohibited items, The 6 items in the restricted category have effectively forced enterprises to increase investment in safety and accelerate the improvement of intrinsic safety levels and safety assurance capabilities.

微信扫一扫打赏

微信扫一扫打赏