On June 29, Hanwha Total Energy, a 50:50 joint venture between Hanwha Solutions and Total Energy in South Korea, has completed a new pilot plant for polyolefin elastomers (POE) construction. This is the “first joint project” undertaken by the joint venture partners.

The device is located in the joint venture factory in Daegu, eastern South Korea, with a POE capacity of 200 tons/year and supports process testing. Hanwha will provide POE production process technology, and Total Energy will provide catalyst technology. The underlying goal is to complete the basic design of a commercial POE plant based on process and catalyst technology within one year.

The project invested 34 billion won (approximately 187 million yuan) and will last 18 months from August 2021. Low density, high elasticity and impact strength make POE suitable for applications such as automotive interior and exterior; food packaging, footwear and wiring.

POE is increasingly being used as a thin-film material for solar panels and the global market is expected to grow at an annual rate of 6.9% to $6.3 billion by 2030, the company added.

Polyolefin Elastomer (POE)

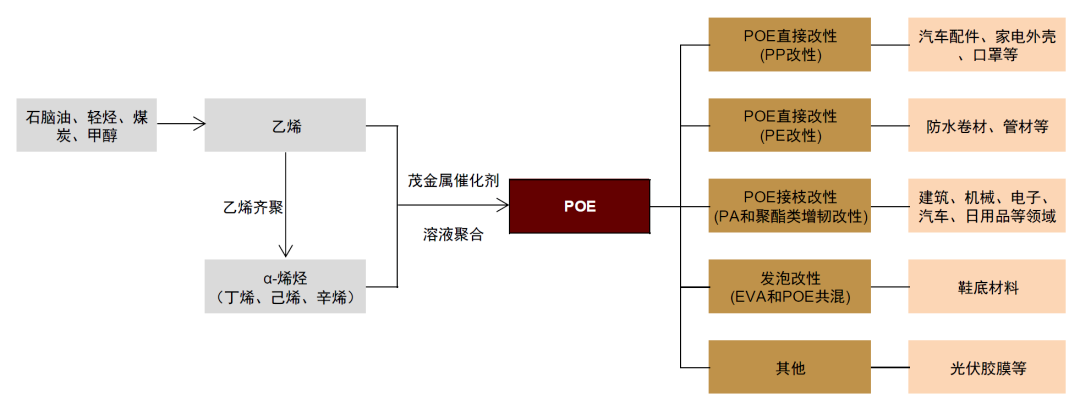

Polyolefin elastomer (POE) is a random copolymer formed by solution polymerization process of ethylene or propylene and α-olefin (1-butene, 1-hexene, 1-octene) under the action of metallocene catalyst , and its downstream applications are extensive, mainly used in auto parts, polymer modification, wire and cable and other fields.

The application of POE materials in my country started late, and the initial consumption structure was dominated by the automobile industry, accounting for 68% of the total consumption; but in 2021, the photovoltaic field will overtake the automobile market and become the largest single market.

微信扫一扫打赏

微信扫一扫打赏