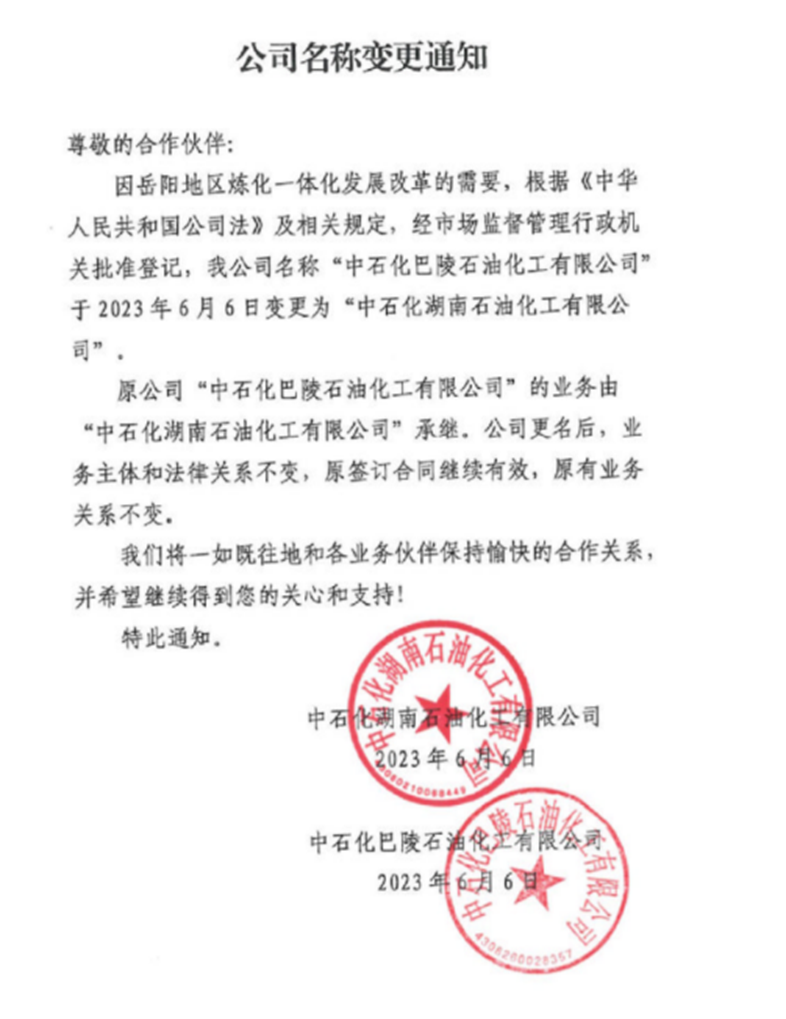

Affected by the merger of Baling Petrochemical and Changling Refining & Chemical to form “Sinopec Hunan Petrochemical Co., Ltd.”, the “Baling Petrochemical 170,000 tons/year high-performance epoxy resin Project”, on July 4, under the name of the new company name Sinopec Hunan Petrochemical Co., Ltd. (Hunan Petrochemical), the environmental impact assessment was announced again on the website of the Hunan Department of Ecology and Environment.

As the first key material project of Hunan Petrochemical, the 170,000-ton high-performance epoxy resin plant construction project is located in the Baling area of Hunan Yueyang Green Chemical High-tech Industrial Development Zone.

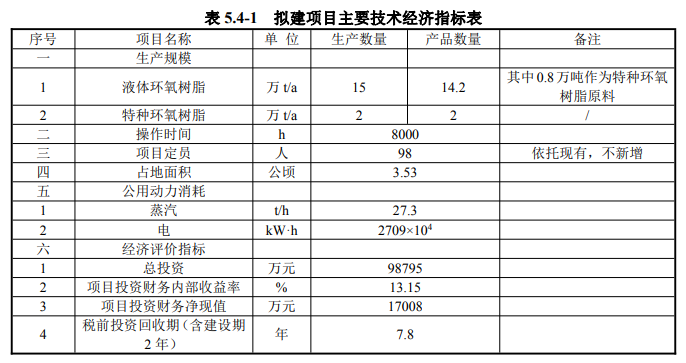

The 10,000-ton/year high-performance epoxy resin plant and supporting facilities, the scale and process of the existing production plant of the resin department remain unchanged. The total planned investment of the project is 988 million yuan, and the estimated construction period is 24 months.

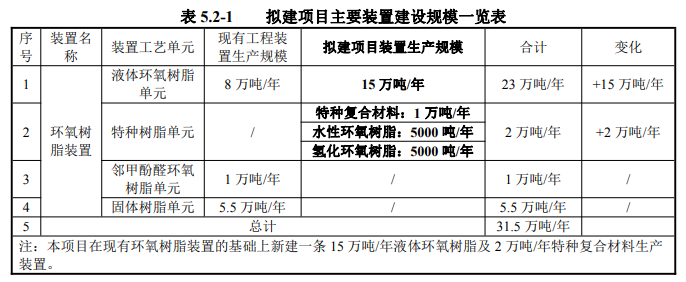

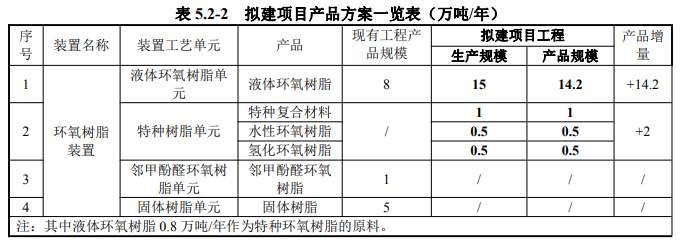

The project plans to build 150,000 tons/year of liquid epoxy resin, 10,000 tons/year of special composite materials, 5,000 tons/year of water-based epoxy resin and 5,000 tons/year of hydrogenated epoxy resin. A new 150,000-ton/year liquid epoxy resin and 20,000-ton/year special composite material production facility will be built on the basis of the project. After the completion of the project, Hunan Petrochemical’s epoxy resin production capacity will increase to 315,000 tons/year.

According to the analysis of the main economic indicators of the project investment, the financial internal rate of return of the project investment is 13.15%, and it is estimated that the investment can be recovered in 7.8 years.

On March 22, 2022, Sinopec and Hunan Province signed a cooperation framework agreement on the integrated ethylene refining and chemical project in Yueyang. The total investment of the project reached 32.85 billion yuan, ranking first among the top ten industrial projects in Hunan Province in 2023. It was jointly constructed by Baling Petrochemical and Changling Refining & Chemical. The overall project is a 1 million tons/year ethylene refining and chemical integration project, including a new 1 million tons/year ethylene unit and a total of 14 downstream units, including ethylene units, EVA units, HDPE units, LLDPE units, aromatics benzene units, butane Diene extraction unit, MTBE/butene-1 unit, pyrolysis gasoline hydrogenation unit, aromatics extraction unit, styrene extraction unit, C5 separation unit, CHPPO unit, phenol/acetone unit, bisphenol A unit, supporting at the same time Construct necessary storage and transportation projects, public works, auxiliary facilities and off-site projects.

On May 27, 2023, the preparatory group of Sinopec Hunan Petrochemical Co., Ltd. was established, marking the official implementation of the integrated development and reform of the two plants of Baling Petrochemical and Changling Refining and Chemical in Yueyang area. On June 6, Baling Petrochemical and Changling Petrochemical successfully merged to become Sinopec Hunan Petrochemical. In 2022, the revenue of Baling Petrochemical will be 19.2 billion yuan, and that of Changling Petrochemical will be 55.6 billion yuan. After the Yueyang refining and chemical integration project is completed and put into operation, the annual revenue is expected to exceed 20 billion yuan.

Baling Petroleum

Sinopec Baling Petrochemical Co., Ltd. is a large-scale petrochemical and coal chemical joint enterprise directly under Sinopec. It is located in Yueyang City, Hunan Province. It was founded in September 1969. It is the largest lithium-based rubber and caprolactam manufacturer in China. Oxygen resin production base. There are 50 sets of main production equipment, supporting public works such as 2 regional thermal power centers and 3 sewage treatment centers, mainly including 5 product chains of oil refining, synthetic rubber, epoxy resin, caprolactam, and coal chemical industry. It is the first lithium-based rubber production base in Asia and the second in the world. Its production technology and catalyst comprehensive technology are at the advanced level in the world. It has the most complete varieties and grades in China and the best quality. Moreover, it has mastered a new generation of process technologies such as cyclohexanone ammoximation, esterification and hydrogenation to cyclohexanone, and slurry bed hydrogen peroxide; it is the only epoxy resin production base in China and Sinopec, and its comprehensive technology ranks in the forefront of the country. It took the lead in developing the industry-leading new process of environmentally friendly epichlorohydrin. At present, Baling Petrochemical is developing and promoting a number of large-scale key projects in China in accordance with the vision and goal of building a world-leading chemical material enterprise and the development path of “developing Baling based on Baling and developing Baling out of Baling”. The 600,000 tons/year caprolactam relocation and upgrading project in Yueyang area has a total investment of 15 billion yuan. After completion, it will become the caprolactam production base with the most advanced technology and the largest scale of a single set of equipment in the world.

Changling Refinery

Sinopec Changling Refining & Chemical is the collective name of Changling Branch of Sinopec Corporation and Changling Branch of Sinopec Asset Management Co., Ltd. The company is a large state-owned enterprise integrating oil refining and chemical production. It is located in Yunxi District, Yueyang City, Hunan Province. It is adjacent to the Yangtze River in the north, Beijing-Guangzhou Railway in the south, and Beijing-Zhuhai Expressway and National Highway 107. The water and land transportation is convenient.

Changling Refining & Chemical Company, formerly known as Changling Oil Refinery, was built in 1965 at the peak of the “Third Line” construction, and was completed and put into operation on May 7, 1971. The company’s existing total assets are 10.123 billion yuan, covering an area of 7.58 square kilometers. The primary processing capacity of oil refining is 11.5 million tons per year, and the comprehensive supporting processing capacity is 8 million tons per year. It has 30 sets of main refining and chemical production equipment and supporting public works , storage and transportation, environmental protection treatment and other devices, among which the production capacity of special chemical devices is 470,000 tons per year, and the main products are gasoline, diesel, aviation fuel, naphtha, liquefied petroleum gas, triphenyl, asphalt, propylene oxide, polypropylene There are more than 60 kinds of products, and 17 kinds of products have won the title of high-quality products above the provincial and ministerial level. The company processes 7 million tons of crude oil on average annually, with an operating income of 40 billion yuan and profits and taxes of about 10 billion yuan.

微信扫一扫打赏

微信扫一扫打赏