On July 4th, Hongbaoli released the draft of the Environmental Impact Report of the Propylene Oxide Comprehensive Technical Transformation Project, and put forward suggestions and opinions on the project construction content for the general public.

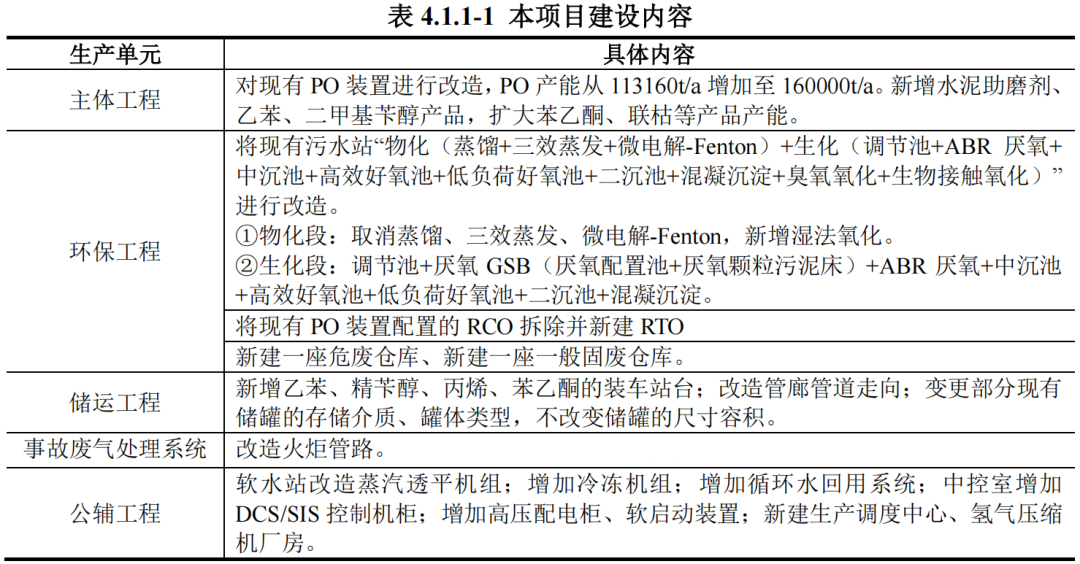

The main project of the project will transform the existing PO device, and the PO production capacity will increase from 113,160 tons/year to

160000 tons/year. Add cement grinding aids, ethylbenzene, dimethyl benzyl alcohol products, and expand the production capacity of acetophenone, lianqua and other products.

Project Summary

Construction unit: Hongbaoli Group Taixing Chemical Co., Ltd.

Project Name: Propylene Oxide Comprehensive Technical Transformation Project

Project Nature: Renovation

Project address: No. 29, Chengjiang West 1st Road, Economic Development Zone, Taixing City, in the existing factory area of Hongbaoli Group Taixing Chemical Co., Ltd.

Project investment: 510.8503 million yuan, including 37.48 million yuan for environmental protection

Occupation area: no new land occupation, carried out in the existing factory area

Number of employees: 31 new employees will be added to the project

Construction content: Relying on the existing equipment and facilities for sewage treatment station, 1# transformer and distribution station, soft water station/air compressor station, circulating propylene compressor plant, tank farm, loading and unloading (including propylene delivery and loading), oxidation air compressor house, circulating water station, hazardous waste incinerator, torch system, overhead pipe gallery, etc., and at the same time use the existing open space to build workshops, dispatch centers, warehouses, RTO devices, waste water tank farms, etc.; purchase reactors, Distillation tower, heat exchanger, hydrogen compressor, wet oxidation device, control cabinet, refrigeration unit, waste water extraction and recovery system and other equipment.

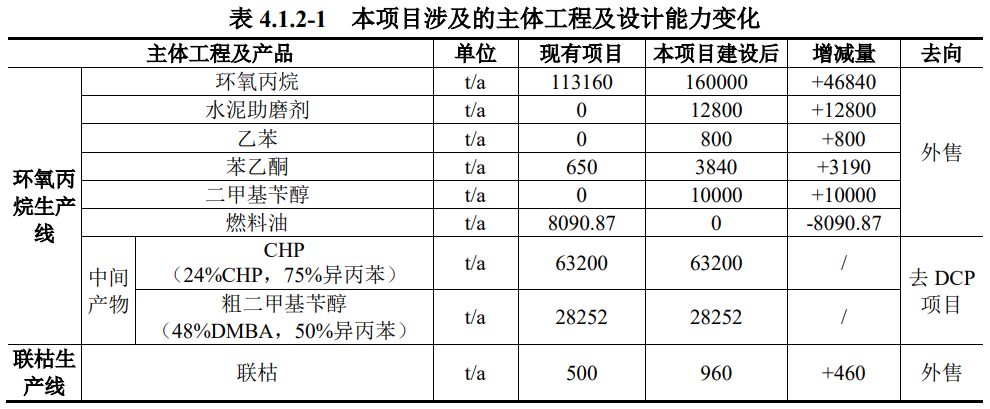

The main works of the project are the propylene oxide production line and the combined drying production line. The main works involved and the changes in the design capabilities of each product before and after completion are as follows:

There are mainly five kinds of propylene oxide production technology, namely the traditional chlorohydrin method and advanced co-oxidation method (propylene oxide/SM method, propylene oxide/TBA method), cumene oxidation method (CHP propylene oxide method ), hydrogen peroxide oxidation (HP propylene oxide method) and O2 direct oxidation method. In February 2019, the 120,000-ton PO plant of Hongbaoli Group was successfully put into operation, adopting a new CHP co-oxidation process independently developed, which is the first set of this process in China.

微信扫一扫打赏

微信扫一扫打赏