Hexafluorobutadiene is mainly used in semiconductor etching. There is broad room for domestic substitution in the Chinese market in the future.

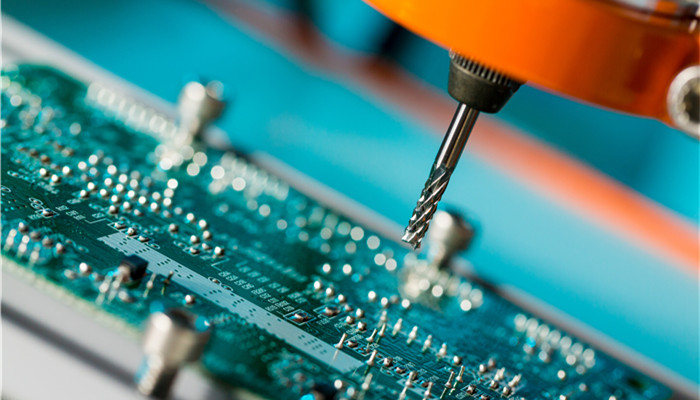

Hexafluorobutadiene, also known as perfluorobutadiene, is an organic chemical with the chemical formula C4F6. It appears as a colorless and transparent liquid. It is a new type of fluorine-containing electron gas that can be used as a polymer monomer. , synthetic intermediates are used in the production of chemical products such as synthetic resins and fluorine-containing substances. They can also be used as etching gases in semiconductor etching processes, and the market demand is wide.

Among them, semiconductors are the main application field of hexafluorobutadiene. In this field, hexafluorobutadiene is mainly used as an electronic special gas in the semiconductor etching process. Compared with traditional perfluoroalkane (PFCs) etching gas, hexafluorobutadiene Butadiene has better selectivity, environmental protection, etching precision, etching efficiency, etc.

In the context of the rapid development of the global semiconductor industry, the demand for etching gases used in the etching field is increasing. As a special electronic gas that can take into account performance, precision and environmental protection, hexafluorobutadiene has gradually become a key component of semiconductor etching. One of the important gases required, the market demand continues to increase. The global hexafluorobutadiene market size will reach US$350 million in 2022, a year-on-year growth of 7.2%.

From the production side, the main production methods for hexafluorobutadiene include the trifluorotrichloroethane method, which uses trifluorotrichloroethane as raw material, dechlorination of zinc powder, addition of iodine chloride, mercury catalysis, and light coupling. The intermediate hexafluorotetrachlorobutane is generated in other steps, and then hexafluorobutadiene is obtained through dechlorination of zinc powder; the chloroform method refers to using chloroform as the raw material and producing the intermediate octafluorobutadiene through a chemical reaction. A method of using dibromobutane or octafluorodiiodobutane to generate hexafluorobutadiene through dechlorination.

According to the “2023-2028 Hexafluorobutadiene Industry Market In-depth Research and Investment Prospects Forecast Analysis Report” released by the Industrial Research Center It shows that due to technical limitations, for a long time, the global core technology of hexafluorobutadiene has been mainly controlled by companies in developed countries such as Japan, South Korea, and Germany, including Ausimont of Germany, Linde Gas of Germany, SK Materials of South Korea, Showa Denko of Japan, and Dai Yangri acid, etc.

my country’s hexafluorobutadiene industry started late, but driven by the growth of downstream market demand, domestic companies entering the field of hexafluorobutadiene R&D and production are continuing to increase, mainly including Nanda Optoelectronics, Sinochem Blue Sky, Jianyang Jinshi Fluorine Industry, Jinhong Gas, Shandong Feiyuan Gas, Heyuan Gas, Walter Gas, CSSC Special Gas, Zhongjuxin Technology, etc. In the future, as local companies continue to upgrade their technologies, the localization level of my country’s hexafluorobutadiene market is expected to continue to improve.

Industry analysts said that hexafluorobutadiene is an important type of electronic specialty gas that can be used in a wide range of Used in the etching process of semiconductor manufacturing processes. From the perspective of the domestic market, under the current background of rapid development of the domestic semiconductor industry, the demand for hexafluorobutadiene continues to increase, and the industry development prospects are good. However, due to technical limitations, my country’s hexafluorobutadiene market is still dominated by international companies. In the future, local companies will need to continue to improve their technical levels and promote the continuous improvement of localization levels.

微信扫一扫打赏

微信扫一扫打赏