Research Report on Development Status and Prospects of China’s High Barrier Film Market in 2023

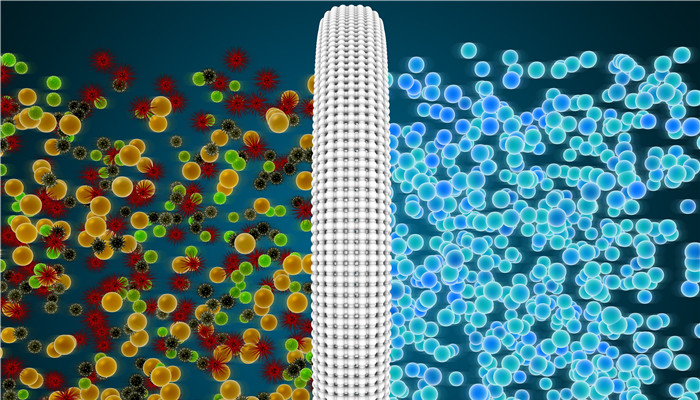

High barrier film is a multi-layer structure film made by simultaneously extruding materials with strong gas barrier properties and polyolefin with strong heat seaming and moisture barrier properties. It has excellent gas and moisture barrier properties and can extend food shelves. period, ensuring the timeliness of medicines and increasing the service life of electronic products. According to materials, high barrier films can be mainly divided into PVA (polyvinyl alcohol) high barrier film, EVOH (ethylene vinyl alcohol copolymer) high barrier film, PVDC (polyvinylidene chloride) high barrier film, high barrier plating film Aluminum film, inorganic oxide film and other types.

According to the “2023-2028 High Barrier Film Industry In-depth Market Research and Investment Strategy Suggestion Report” released by the Industrial Research Center, high Barrier films can be widely used downstream in food, medicine, electronics and other industries. Against the background of the continuous development of downstream industries, the global market for high barrier films continues to expand. In 2022, the global high barrier film market will exceed 69 billion yuan. The Asia-Pacific region is one of the major demand markets for high-barrier films in the world, with demand accounting for nearly 1/3. In the Asia-Pacific market, China is the main demand country for high-barrier films. In 2022, China’s high-barrier film market will exceed 16 billion yuan, accounting for 23% of the global market.

With the continuous advancement of technology, the continuous expansion of downstream markets and the continuous improvement of requirements, the performance of high-barrier films is constantly being upgraded. Traditional high barrier films are organic films, represented by PVA high barrier films, EVOH high barrier films, and PVDC high barrier films. The new generation of high barrier films are inorganic oxide films, which are made by evaporating or depositing inorganic layers such as silicon oxide and aluminum oxide on the surface of traditional organic films. In addition to having excellent barrier properties, this type of high barrier film also It can also be heated directly, which is safer.

The technical barriers to high barrier films are high. In the early days, the global market was mainly monopolized by European, American and Japanese companies. Representative companies include Dow Chemical Company of the United States, Kureha Chemical Company of Japan, Asahi Kasei Company of Japan, Akzo Nobel Company of the Netherlands, etc. Driven by demand, China’s high-barrier film industry has gradually developed and grown, and now has independent production capabilities. Representative companies include Shanghai Yongchao New Material Technology Co., Ltd., Huangshan Yongxin Co., Ltd., and Jiaxing Pengxiang Packaging Materials Co., Ltd. , Guangdong Zhengyi Packaging Co., Ltd., etc.

Industry analysts said that the number of high-barrier film manufacturers in my country is increasing, but compared with European, American and Japanese companies, due to the initial start of the industry It is late, with insufficient accumulation of technology and experience, and weak innovation capabilities. The products produced are mainly concentrated in the low-end market, and high-end demand is still highly dependent on imports. In addition, most companies in my country’s high-barrier film industry focus on developing segmented products and have certain competitiveness in some segments. However, there has yet to be a leading company with large scale, strong strength and absolute competitive advantages. Overall, there is still much room for improvement in my country’s high-barrier film industry in the future.

微信扫一扫打赏

微信扫一扫打赏