SiCf/SiC composite materials are key materials for a new generation of aero-engines and have huge market development potential.

SiCf/SiC composite material, the full name of silicon carbide fiber reinforced silicon carbide ceramic matrix composite material, refers to a composite material formed by introducing silicon carbide fiber reinforcement into a silicon carbide ceramic matrix. The main production methods of SiCf/SiC composite materials include polymer impregnation pyrolysis (PIP), chemical vapor infiltration (CVI), reaction infiltration sintering (RI), etc. Among them, the RI method is the most promising production method for SiCf/SiC composite materials. It has the advantages of low production cost, short cycle, and low material porosity.

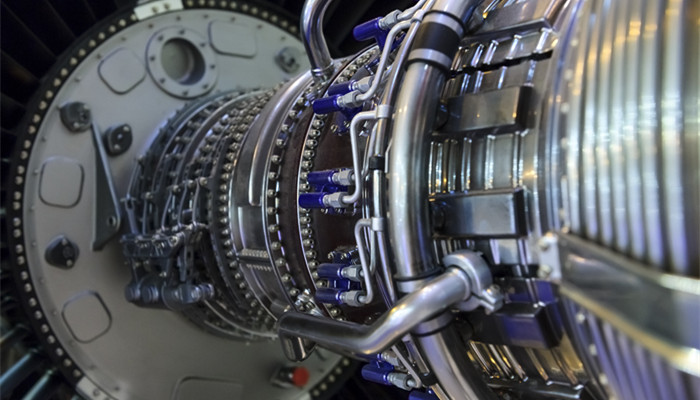

SiCf/SiC composite material is a type of high-performance ceramic matrix composite (CMC). On the basis of retaining the high strength and good high temperature resistance of silicon carbide ceramics, it also has high specific stiffness, low density, high durability and excellent strength. Its high temperature mechanical properties, oxidation resistance, radiation resistance, corrosion resistance and other properties have broad application prospects in aerospace, nuclear energy and other fields, especially in turbine blades, nozzle guide vanes, and combustion chamber linings of aerospace engines. , tail nozzle and nuclear fuel cladding tube and other components.

According to the “2023-2028 SiCf/SiC Composite Materials Industry Market In-depth Research and Investment Prospects Forecast Analysis Report” released by the Industrial Research Center It shows that turbine blades are one of the key components of aeroengines and are currently mainly made of high-temperature alloys. In 2022, the global market size of high-temperature alloys used in turbine blades will exceed US$12 billion. As a new blade material, SiCf/SiC composite materials have higher temperature-bearing performance, flexibility performance, and durable strength at high temperatures than high-temperature alloys. In the future, as technology continues to upgrade, it is expected to accelerate the replacement of high-temperature alloys, and the industry has broad development prospects. .

As a promising material for hot-end components of aerospace engines, SiCf/SiC composite materials have become a hot research and development area for domestic and foreign enterprises and institutions. In the 1980s, France’s SNECMA had successfully developed SiC/SiC composite materials for use in the tail nozzles of aircraft engines. Since then, as various countries have continued to increase their research and development efforts, developed countries such as the United States and Japan have also successfully developed SiCf /SiC composite material products, and after nearly 50 years of development, this material has achieved industrial production and has become a typical material for the new generation of aeroengines.

During the same period in the 1980s, my country’s research on SiCf/SiC composite components was still in its preliminary stages, and the industry started late. After recent years of development, my country has developed the mass production capacity of SiCf/SiC composite materials. However, there is still a certain gap between China and international advanced enterprises in terms of production technology, product performance, and production scale. In the future, local enterprises will need to continue to increase research and development. intensity.

Industry analysts said that currently domestic institutions and enterprises in the field of R&D and production of SiCf/SiC composite materials Mainly include China Aviation Development Shenyang Liming Aero Engine, Shenyang University of Aeronautics and Astronautics, Beijing University of Aeronautics and Astronautics, Northwestern Polytechnical University, China Aviation Development Power Co., Ltd., CNNC Northern Nuclear Fuel Elements, Hunan Zerui New Materials, Suzhou Hongjiu Aviation Thermal Protection Material Technology, Chengdu Tianxiang Power Technology Research Institute, etc.

微信扫一扫打赏

微信扫一扫打赏