On April 25, North Huajin United Petrochemical Co., Ltd. 20

10,000 tons/year of high-density polyethylene, 300,000 tons/year of propylene oxide, 220,000 tons/year of hydrogen peroxide (100%), and 1.6 million tons/year of delayed coking projects will be publicized for the second environmental impact assessment.

200,000 tons/year high-density polyethylene plant

Project name: 200,000 tons/year high-density polyethylene plant of North Huajin United Petrochemical Co., Ltd.

Construction location: The starting area of Liaodong Bay New District, Panjin (key construction area).

Construction content and scale: The main device is a 200,000-ton/year high-density polyethylene device, and supporting public and auxiliary and storage and transportation facilities will be built at the same time. The project covers an area of 3.84 hectares, with an annual operating time of 8000 hours and 41 new labor capacity. The total investment is 779 million yuan.

Project investment: The total project investment is 779 million yuan, of which environmental protection investment is 15.91 million yuan, and environmental protection investment accounts for 2%.

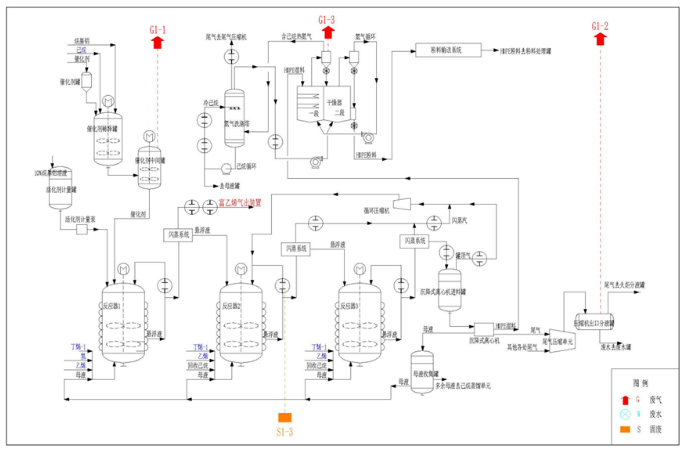

Introduction to the device: The construction scale of the new high-density polyethylene plant is 200,000 t/a. The ethylene produced by the Huajin Project is used as the main raw material, and the main product is high-density polyethylene, which is directly used as the product sale. The device adopts the ethylene slurry polymerization process independently developed by Sinopec. The operating flexibility of the device is 60%~110%, and the annual operating hours are calculated as 8,000 hours.

Technical characteristics: This device adopts the Sinopec slurry process technology, with high-purity ethylene as the main raw material, hexane as the solvent, and high-efficiency catalysts. By changing the operating conditions, parallel or series polymerization processes and adding Comonomer butene-1 to obtain various grades of high-density polyethylene.

It has the characteristics of simple process flow, mild reaction conditions, low catalyst requirements for raw material impurities, excellent product performance, low operating costs, low catalyst consumption, fast product grade conversion, and less transitional materials.

300,000 tons/year propylene oxide plant

Project name: North Huajin United Petrochemical Co., Ltd. 300,000 tons/year propylene oxide plant.

Construction location: The starting area of Liaodong Bay New District, Panjin (key construction area).

Construction content and scale: The main device is a 300,000-ton/year propylene oxide device, and supporting public and auxiliary and storage and transportation facilities will be built at the same time. The project covers an area of 7.65 hectares, with an annual operating time of 8000 hours and 76 new labor capacity. The total investment is 2 billion yuan.

Project investment: The total investment of the project is 2,002.46 million yuan, of which 129.71 million yuan is invested in environmental protection, accounting for 6.5% of the total investment.

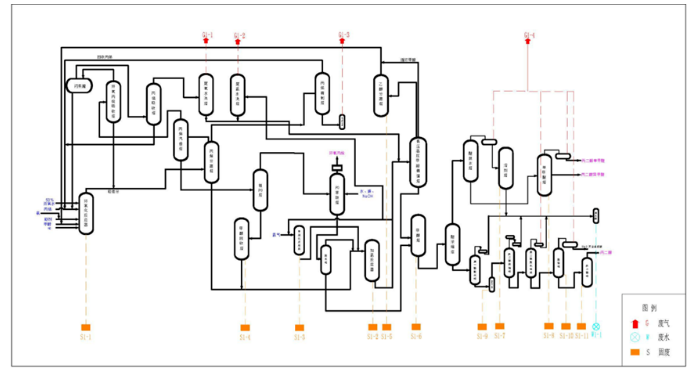

Introduction to the device: The construction scale of the new propylene oxide plant is 300,000 t/a, using the propylene produced by the Huajin Project and the hydrogen peroxide produced by the hydrogen peroxide plant under construction simultaneously with this project as the main raw materials. The main product produced is propylene oxide, which is directly sold as a product. The device adopts the hydrogen peroxide direct oxidation process, the operating flexibility of the device is 60%~110%, and the annual operating hours are calculated as 8000 hours.

Technical characteristics: The main reaction of this process is epoxidation reaction. At a certain temperature, propylene and hydrogen peroxide undergo an epoxidation reaction on a titanium-silicon molecular sieve catalyst to generate propylene oxide and water. It has the characteristics of mild conditions, simple process, good product selectivity, environmental friendliness and high atom utilization rate.

微信扫一扫打赏

微信扫一扫打赏