April 2023, global color management experts –

X-Rite installed online color measurement equipment for Nanya Plastic Industry (Nantong) Co., Ltd. (hereinafter referred to as “Nanya Company”), helping it enter a new era of automatic color management on production lines. With its advanced management experience, Nanya Company has been committed to realizing intelligent production and data management for many years. With its rich experience in color data management, X-Rite has won the favor of Nanya Company and further expanded the long-term cooperative relationship between the two companies.

Nanya Company hopes to optimize the process and improve efficiency by monitoring the color change trend in the production process in real time. However, in the actual production process, Nanya Company found that the traditional offline color measurement method often requires multiple steps such as sampling, sample delivery, and color measurement, which is cumbersome and inefficient. And once the color problem is discovered after production, it will cause a lot of waste and money loss, and it is also not conducive to the sustainable development of the company. In order to better realize intelligent production and data-based color management, Nanya Company began to consult X-Rite for online color measurement equipment, hoping that X-Rite can help it find color abnormalities and changes in the production process in real time and adjust them in time to reduce unnecessary The number of qualified products can be reduced to optimize the production process, improve production efficiency and product quality.

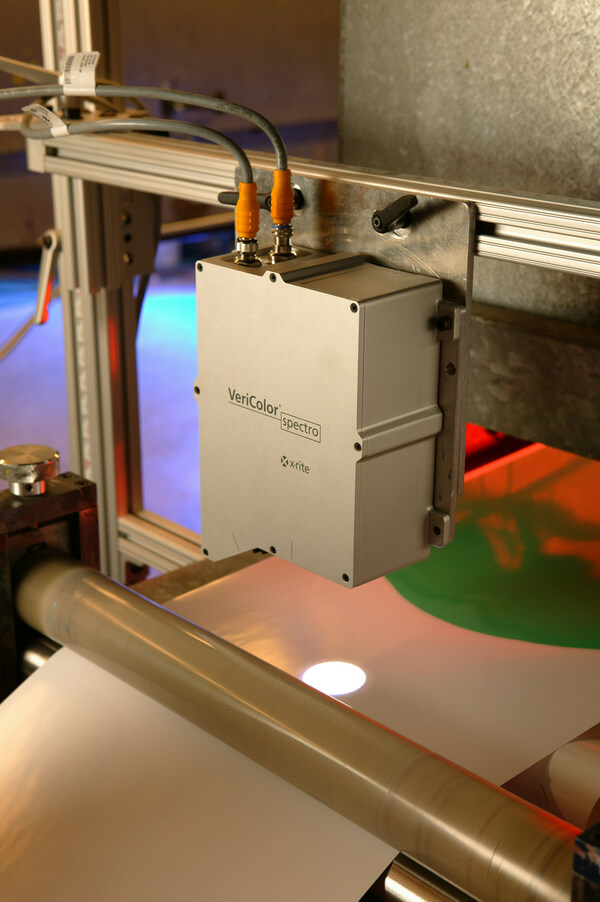

X-Rite VS410 Online Color Measurement Equipment

Aiming at the current challenges faced by Nanya Company, X-Rite recommended VS410 online color measurement equipment to it. The device is compact and durable, can achieve accurate measurement and can provide flexible in-line installation conditions. Coupled with an environmental protection cover, it can also prevent dust and humidity and increase the measurement temperature of the instrument to 75 degrees. Through this cost-effective in-line non-contact color measurement solution, absolute spectral and colorimetric data can be provided for process control, and color non-conforming products can be detected and corrected as early as possible before the product process is completed, reducing scrap costs.

After several on-site communications and tests by X-Rite color engineers, Nanya successfully installed X-Rite VS410 online color measurement equipment on the production line. Through this equipment, Nanya Company has realized the real-time continuous detection of color trend changes of products during the production process, eliminating color problems caused by human errors or lack of experience, so as to ensure the color stability of products. It is also worth mentioning that online color measurement does not require downtime or unwinding destructive sampling, which can greatly accelerate the process of the color reaching the target color and improve efficiency when starting up or changing production. In addition, after the online equipment is calibrated with the laboratory colorimeter, it can be completely used as the color inspection standard of the production line products, reducing the frequency of off-line sampling in the personnel laboratory. No matter what kind of production requirements, adding automatic color management on the production line is a convenient way for factories to achieve accurate and consistent colors. It helps manufacturers realize the transformation from traditional manual color matching to automated and digital production processes. To achieve color consistency, improve the market competitiveness of enterprises, and enhance customer satisfaction.

VS410 production line installation diagram

Talking about this cooperation, the production manager of Nanya Company said: “With X-Rite

VS410 online color measurement solution, we can measure, analyze and control the color of the sample in real time, and correct the color deviation without stopping the production, which makes the color quality control on the production line more efficient, no longer need to wait for the sample to go offline measurement results. At the same time, this also improves our customer satisfaction, product qualification rate and profit margin, and enables us to establish a more sustainable production workflow, which is the main reason why we choose X-Rite VS410. ”

微信扫一扫打赏

微信扫一扫打赏