The development opportunities and challenges of the borophosphosilicate glass (BPSG) industry coexist and there is huge room for future growth.

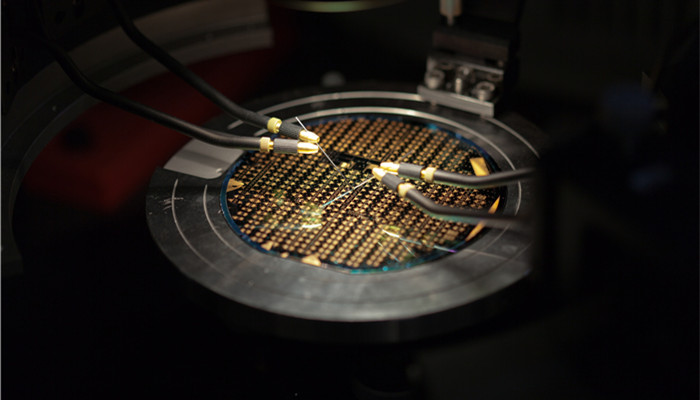

Boro-phospho-silicate Glass, or BPSG for short, refers to a silicon oxide layer formed by simultaneously doping phosphorus impurities and boron impurities into silicon dioxide (SiO2). It is often used in the front-end manufacturing process of semiconductor chips. The front-end manufacturing process of semiconductor chips mainly includes oxidation diffusion, thin film deposition, glue development, photolithography, ion implantation, etching, cleaning, etc. Among them, thin film deposition is the core process of chip front-end manufacturing. It refers to the process of depositing specific materials on the substrate to form a thin film, so that it has special optical, electrical and other properties. Boron phosphosilicate glass is a type of dielectric film widely used in thin film deposition processes.

Compared with similar products, phosphosilicate glass, borophosphosilicate glass has superior hole filling ability, high temperature flow ability, and ability to absorb and block sodium ions. It can greatly improve the surface planarization of silicon wafers, thus providing better conditions for photolithography and back-end manufacturing. The process provides a wider process range and is mainly used as pre-metal dielectric (PMD) and inter-metal dielectric (AVID).

According to the“Borophosphosilicate Glass (BPSG) Industry Market In-depth Research and Investment Prospects Forecast Analysis Report 2023-2028” released by the Industrial Research Center shows that in recent years, as chip manufacturing processes have become more advanced, the number of thin film deposition processes and layers has increased, which has led to an increase in the number of metal layers. As the most commonly used pre-metal dielectric and inter-metal dielectric, the market demand for borophosphosilicate glass continues to grow, and the industry shows good development prospects.

At present, there are two main manufacturing methods for borophosphosilicate glass: PECVD (Plasma Enhanced Chemical Vapor Deposition) and SACVD (Sub-Atmospheric Pressure Chemical Vapor Deposition). Among them, SACVD refers to using TEOS, TEB, TEPO and other liquids as silicon source, boron source and phosphorus source to enter the reaction chamber through gasification in a sub-normal pressure environment, and then accurately controlling the gas pressure and temperature in the chamber. The process of depositing gas phase chemical reaction materials on the surface of a wafer to form a thin film. The SACVD process has the advantages of faster deposition speed and stronger filling ability of high aspect ratio trenches. It is currently the main production process of borophosphosilicate glass.

TEOS (tetraoxysilane), TEB (triethoxyborane), and TEPO (triethyl phosphate) are important raw materials for the production of borophosphosilicate glass. Currently, domestic companies are developing electronic-grade TEOS, TEB, and TEPO material markets. The quantity is still relatively small and the production capacity is still relatively low. In the future, local companies will need to continuously improve their technology and technology to accelerate the breakthrough of raw material difficulties.

Industrial analysis personnel said that at the same time, borophosphosilicate glass is mainly made by SACVD equipment. At present, domestic Only one company, Tuojing Technology, has realized the industrial application of SACVD equipment. In the future, against the backdrop of continued growth in demand for borophosphosilicate glass, the localization process of SACVD equipment needs to continue to accelerate. Overall, as the domestic semiconductor chip manufacturing process becomes more and more advanced, the market demand for borophosphosilicate glass continues to increase, and the industry development prospects are good. But at the same time, the development of the domestic borophosphosilicate glass industry is still facing difficulties such as low raw material supply capacity and low localization of production equipment. There is still huge room for growth in the industry in the future.

微信扫一扫打赏

微信扫一扫打赏