The scale of the polyphenylene ether market continues to expand, and local companies still have greater room for development.

Polyphenylene ether is also called polyphenylene oxide or polyphenylene ether, referred to as PPO or PPE. Polyphenylene ether is one of the five major engineering plastics and has the characteristics of good electrical insulation, high heat resistance, and good dimensional stability. Polyphenylene ether is usually polymerized with HIPS, ABS and other materials to improve product performance.

The production processes of polyphenylene ether mainly include precipitation polymerization and solution polymerization. The precipitation polymerization method has low monomer purity requirements and few operating procedures. The disadvantage is that the yield is low and washing is difficult during post-processing; the solution polymerization method has a high yield, generally up to 95% or more, low impurity content, and excellent color and performance. The disadvantage is that it requires higher monomer purity.

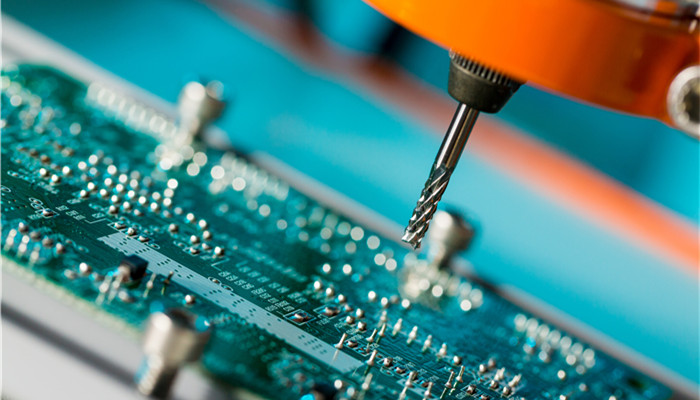

Polyphenylene ether is mostly used in electronics, automobiles, household appliances and other fields. In the field of electronic appliances, polyphenylene ether is mainly used to produce coil winding bobbins, switching relays, variable capacitors, large electronic displays, etc.; in the automotive industry, polyphenylene ether is mainly used to produce automotive dashboards, radiator grilles, fuse boxes, etc. Speaker grilles, etc.; in household appliances, polyphenylene ether is mainly used in the manufacturing of televisions, air conditioners, heaters, rice cookers and other parts. As electronic appliances and automobiles develop in the direction of lightweighting, the dimensional stability and electrical insulation properties of polyphenylene ether are further highlighted, and market demand will further increase.

Due to high industry barriers, the global polyphenylene ether market is monopolized by several companies. At present, the main companies that produce polyphenylene ether are Saudi Basic Industries Corporation (SABIC), Asahi Kasei Chemicals, Romira (BASF), Bluestar, Mitsubishi Chemicals, etc. The total market share of these companies is about 86%. Due to the small number of manufacturing companies and limited production capacity of polyphenylene ether, the market is in short supply. As the application scenarios of polyphenylene ether expand, the demand continues to increase and the market scale continues to expand. The global polyphenylene ether market size will be 7.48 billion yuan in 2022, and is expected to reach 8.71 billion yuan in 2028.

According to the “China Polyphenylene Ether (PPO) Industry Market Monitoring and Future Development Prospects Research Report 2023-2028” released by the Industrial Research Center shows that at present, domestic polyphenylene ether manufacturers are mainly Nantong Xingchen and Xinbao New Materials. Among them, Nantong Xingchen has broken technical barriers and enabled my country’s polyphenylene ether market to get rid of the previous situation of being completely dependent on imports. In 2020, Nantong Xingchen’s new generation 30,000-ton polyphenylene ether plant was successfully put into operation. The polyphenylene ether resin production capacity can reach 50,000 tons/year, making it the only polyphenylene ether manufacturer in the world that masters two process technologies.

Industry analysts said that after years of technological development, domestic companies have achieved industrialized production of polyphenylene ether, but the output is small and insufficient. Completely covering domestic market demand, the market localization rate is only 31%. And compared with mature polyphenylene ether production technology abroad, domestic polyphenylene ether technology still has some problems. For example, the precipitation polymerization method used by domestic companies is less efficient and requires continuous research and development. In the future, my country’s polyphenylene ether industry still has a long way to go, and local companies still have a lot of room for development.

微信扫一扫打赏

微信扫一扫打赏