Titanium matrix composites (TMCs) have excellent performance and broad application prospects

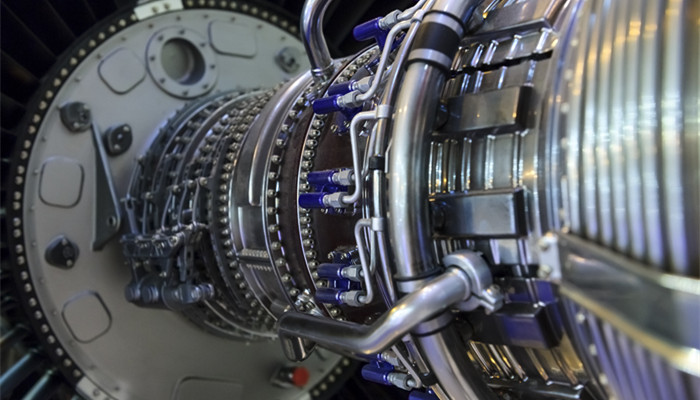

Titanium matrix composites (TMCs) refer to new materials made with titanium as the matrix and polymer materials, fibers, inorganic non-metals, etc. as reinforcements. Titanium-based composite materials have the advantages of high temperature resistance, high specific strength, high specific stiffness, and good creep resistance, and have broad application prospects in the aerospace and military fields. According to different reinforcements, titanium-based composite materials can be divided into continuous fiber-reinforced titanium-based composite materials and discontinuous particle-reinforced titanium-based composite materials.

Preparation methods of titanium-based composite materials include combustion-assisted casting, self-propagating high-temperature synthesis, additive manufacturing, melting and casting, discharge plasma sintering, in-situ synthesis, etc. The melting and casting method is a traditional preparation method for titanium-based composite materials. It has the advantages of low production cost and simple process, but the quality of the finished product is poor. At present, the in-situ synthesis method is a research hotspot for titanium-based composite materials. Compared with traditional methods, it can effectively improve material properties and is expected to become the mainstream preparation method for titanium-based composite materials in the future.

According to the “2023-2028 China Titanium Matrix Composite Materials (TMCs) Industry Market In-depth Research and Development Prospects Forecast Report》shows that titanium-based composite materials have broad application prospects in the aerospace and military fields. In the aerospace field, titanium-based composite materials have excellent performance and can be used to manufacture aircraft parts such as aircraft blades, aircraft fairings, and aircraft tails. In recent years, my country’s aerospace industry has developed rapidly. According to data released by the Civil Aviation Work Conference, in 2022, my country’s civil aviation had 4,165 transport aircraft and 3,177 general aircraft. In this context, my country’s titanium-based composite materials will gain broad market space.

Baoji Titanium Industry Co., Ltd., Hunan Jintian Titanium Technology Co., Ltd., Western Superconducting Materials Technology Co., Ltd., Shaanxi Tiancheng Aviation Materials Co., Ltd., etc. are major players in my country’s titanium-based composite material market. Baoti Co., Ltd. is my country’s leading enterprise of titanium-based composite materials and the main supplier of titanium-based composite materials in the production process of the domestic large aircraft C919. According to the financial report of Baoti Co., Ltd., in the first three quarters of 2022, the company achieved revenue of 5.1 billion yuan, a year-on-year increase of 10.5%.

In recent years, Chinese enterprises and related scientific research institutions have continued to increase their research efforts on titanium-based composite materials and have made many new developments. In 2022, Northwestern Polytechnical University, Xi’an University of Science and Technology and the Northwest Nonferrous Metal Research Institute used a two-step process to successfully prepare titanium-based composite materials with extremely high plastic elongation and strength.

Industry analysts said that titanium-based composite materials have high temperature resistance, high specific strength, high specific stiffness, and good creep resistance. Advantages, widely used in aerospace and other fields. As my country’s aerospace technology continues to make breakthroughs and innovations, the market space for titanium-based composite materials will further expand. In recent years, Chinese enterprises and related scientific research institutions have continued to become more enthusiastic about titanium-based composite materials, further accelerating the development of the industry.

微信扫一扫打赏

微信扫一扫打赏