Membrane contactor is a new separation technology with great room for development in the field of sewage and wastewater treatment.

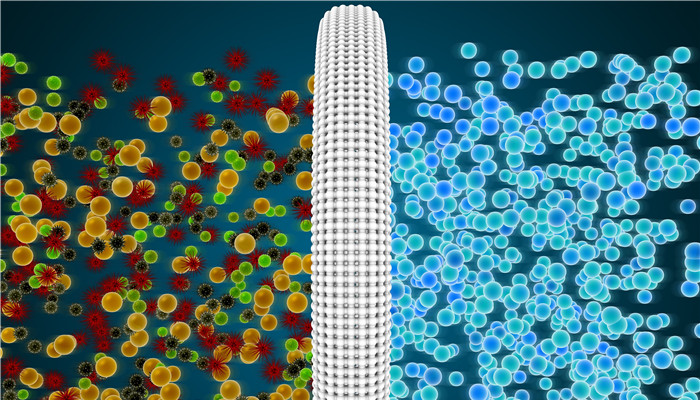

Membrane contactor, its concept is opposite to that of membrane separation. It no longer has selective separation, but realizes two-phase contact of different substances on both sides of the membrane at a certain interface. The materials on both sides of the membrane contactor do not mix with each other, but are transferred from one side to the other through diffusion, thereby achieving material separation. Membrane contactors generally use high molecular polymers such as polypropylene and polytetrafluoroethylene as materials.

Membrane contactors are mainly used for liquid-gas separation. Its technical means mainly include: vacuum, which uses vacuum to create a pressure difference on one side and separates gas from the other side; purge, which uses a certain gas missing on one side to form a partial pressure difference. , to separate the gas on the other side; physical absorption, using the high solubility of a solvent to a certain gas, to dissolve the gas on the other side to achieve separation; chemical absorption, using the reaction between compounds and gases, thereby Separate the gas on the other side.

According to the “China Membrane Contactor Industry Market In-depth Research and Development Prospects Forecast Report 2022-2027” released by the Industrial Research Center, Membrane contactors can be widely used in water purification, sewage treatment, medicine, food and beverage, electronics, chemical industry, metallurgy, petroleum, natural gas and other industries. The main advantages of the membrane contactor are that the operation process is easy to control, the processing efficiency is high, and it can be used in conjunction with membrane extractors, membrane emulsifiers, membrane distillers, etc. to achieve higher-level separation effects.

In metallurgy, chemical industry, electronics, medicine, food and other industries, the discharged condensed water and wastewater contain a large amount of free ammonia nitrogen, which mainly exists in the form of NH3 in the water. Traditional treatment methods for free ammonia nitrogen mainly include chlorination, stripping, gas stripping, etc., all of which have shortcomings. Ammonia nitrogen can be converted into nonionic ammonia, and ammonium sulfate can be formed by reacting with dilute sulfuric acid through a membrane contactor, thereby achieving the purpose of ammonia nitrogen removal. The use of membrane contactors to remove ammonia nitrogen has the advantages of high treatment efficiency, simple operation process, low energy consumption, and low cost. This method can also be used in the field of ammonia nitrogen treatment of landfill leachate.

Our country has a huge population. As living standards improve, the amount of domestic sewage discharged across the country continues to increase. In domestic sewage, there is a high concentration of methane dissolved, which can cause the greenhouse effect. Treatment of methane in sewage is one of the key steps to achieve “carbon neutrality”, and the recovered methane can be reused. The utilization value of methane obtained by recycling domestic sewage using traditional technology is low. A membrane contactor is used to dissolve methane using a non-polar organic solvent as a draw liquid. The treatment efficiency is high and the utilization value of methane is high.

Industry analysts said that membrane contactors have a broad market space, and their manufacturing companies are increasing globally. In overseas markets, the main membrane contactor manufacturers include 3M of the United States, Pure Water of the United States, Entegris of the United States, EUROWATER of Denmark, Compact Membrane Systems of the United Kingdom, etc.; in the Chinese market, the main membrane contactor manufacturers include Hangzhou Cobetter Filtration Equipment Co., Ltd. Company, Anhui Konano Membrane Technology Co., Ltd., Guochu Technology (Xiamen) Co., Ltd., etc.

微信扫一扫打赏

微信扫一扫打赏