The requirements for orthodontic appliances for treating deformed teeth are very high. It must be clinically effective, customizable, invisible and comfortable to wear. The same requirements apply to the material of orthodontic splints. Now, a team at the Fraunhofer Institute for Applied Polymer Research IAP in Potsdam, Germany, in cooperation with the University Hospital Düsseldorf, Germany, has developed a highly innovative material that could enable completely new treatment concepts and reduce costs . Scientists have developed polymers with shape memory properties.

The new material combines efficient tooth movement with more efficient use of resources. Thorsten, head of the research department “Synthesis and Polymer Technology” at the Fraunhofer Institute for Applied Polymer Research IAP

Explaining the concept, Dr. Pretsch said: “Alignments made from shape-memory polymers can control the forces acting on the teeth, making the treatment more patient-friendly.”

“Our aligners allow several steps in orthodontics to be implemented in one go,” says Dr. Thorsten Pretsch. The advantages are:

Reduce the number of aligners during treatment, avoid excessive waste of materials, and reduce treatment costs.

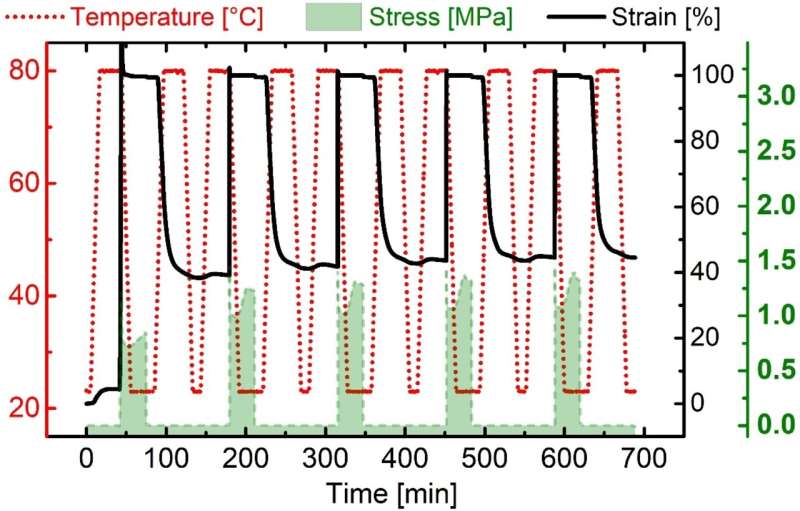

Shape memory polymers are smart materials. Objects made of these plastics can change their shape in a precisely predetermined manner. External stimuli, such as heat, trigger the shape memory effect. The aligners slowly change shape to move the misaligned teeth into the desired position.

Orthodontic material with double effect

Project Leader Fraunhofer Institute for Applied Polymer IAP, MSc Dennis

Schönfeld, synthesized a thermoplastic polyurethane (TPU) for appliance therapy that responds to both heat and body temperature water. Depending on how high or low the temperature is or how much water the material absorbs, the shape change of the appliance can be broken down into many individual steps.

A series of tests were carried out with denture models, and the results verified the functionality of this newly developed TPU:

During the heat treatment, the team achieved a maximum movement of 3.5 millimeters in front teeth. In addition, in water with body temperature, the shape of the aligner can be gradually changed within a specified period of time. In the future, the shape memory effect could be triggered by saliva in the mouth.

Thus, several corrective steps can be achieved with one splint. Clever choice of material thickness and gradual heating of the aligners also control the force exerted on the teeth. Thorsten

Dr. Pretsch emphasizes: “For orthopedic applications, these special features bring a number of unique advantages to appliance treatment – from small shape adjustments through controlled heating to a reduction in the number of treatment steps.”

Making orthodontic treatment sustainable

Until now, aligners have been constructed of materials that generate strong compressive forces. Therefore, many small treatment steps are required to correct the malocclusion without damaging adjacent tissues. Each stage of treatment requires a removable clear aligner. Research recommends limiting tooth movement to a maximum of 0.2 mm per aligner. Therefore, the need to use many individually manufactured splints for treatment results in high costs.

Depending on the extent of the malocclusion, an average of 30 to 60 aligners need to be made to move the teeth into the desired position over a period of several months. The newly developed polymer is able to change shape in pre-determined, small and controllable steps, which has the potential to reduce the number of stages required for orthodontic treatment compared to treatments using traditional aligner materials.

Future Technologies for Dental Treatment

The appliance material developed by researchers at the Fraunhofer Institute for Applied Polymer Research IAP has so far been tested on model dental crowns. In order to optimize its clinical application, the scientists focused on further material development. As a basis, a detailed biomechanical analysis was carried out at the Orthodontic General Hospital of the University Hospital Düsseldorf.

Prof. Drescher from the University Hospital Düsseldorf: “Our investigations have shown that the newly developed material has a remarkable efficiency, which means great advantages for orthodontic treatment.”

The team is confident in transferring this new technology to clinical applications.

微信扫一扫打赏

微信扫一扫打赏