The market demand for perfluorinated ion exchange membranes in my country is strong, and there is huge room for domestic substitution in the future.

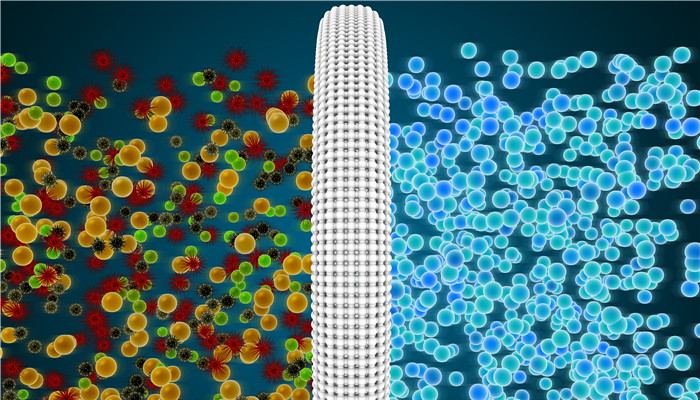

Perfluoro ion exchange membrane, also known as perfluorocarbon ion exchange membrane, refers to an ion exchange membrane prepared by using perfluorosulfonic acid and perfluorocarboxylic acid ion exchange resin. Perfluorinated ion exchange membrane has the advantages of high temperature resistance, corrosion resistance, and good conductivity, and is a key material for the sustainable development of my country’s chlor-alkali industry.

There are three preparation methods for perfluorinated ion exchange membranes: solution steel strip casting, solution casting and melt extrusion casting. The solution steel strip casting method requires heating the film-making liquid and the steel strip to high temperatures, using a casting machine to change the thickness of the cast film, and after cooling, the perfluorinated ion exchange membrane can be obtained. The melt extrusion casting method is the earliest preparation method for perfluorinated ion exchange membranes and is suitable for large-scale production. However, it requires transformation after film formation before it can be used, which can easily affect the performance of perfluorinated ion exchange membranes.

Perfluorinated ion exchange membranes are mainly used in the chlor-alkali industry and proton exchange membrane fuel cells. In the chlor-alkali industry, perfluorinated ion exchange membranes are used in the ion membrane caustic soda process due to their advantages of good electrical conductivity, good chemical stability, and low environmental pollution. Perfluorinated ion exchange membrane is the core raw material of proton exchange membrane fuel cells. Proton exchange membrane fuel cells are in strong demand in the field of new energy vehicles. According to statistics from the China Association of Automobile Manufacturers, my country’s new energy vehicle production will reach 3.545 million units in 2021, a year-on-year increase 159.5%. As end market demand continues to grow, the scale of the perfluorinated ion exchange membrane industry will further expand.

In terms of market competition, the United States and Japan occupy the monopoly position in the global perfluorinated ion exchange membrane industry. DuPont Company of the United States, Asahi Kasei Company of Japan and Asahi Glass Company of Japan are the main suppliers of perfluorinated ion exchange membranes in the world. DuPont in the United States was the first company to produce perfluorinated ion exchange membranes. Driven by technological innovation, the perfluorinated ion exchange membranes produced by DuPont have been widely used in the chlor-alkali industry.

According to the released “2022-2027 China Perfluorinated Ion Exchange Membrane Industry Market Monitoring and Future Development Prospects Research Report“, In the local market, due to factors such as high technical barriers, the development of my country’s perfluorinated ion exchange membrane industry has long lagged behind that of the United States and Japan. In recent years, with the support of national policies, my country’s perfluorinated ion exchange membrane companies have achieved localized technological breakthroughs and large-scale production. Shandong Dongyue Group has the largest fluorosilicone material production base in Asia. In 2020, the company’s “A Perfluorinated Ion Exchange Resin and its Preparation Method and Application” published by the company won the “China Patent Gold Award”.

Industry analysts said that in recent years, my country’s new energy automobile industry has achieved large-scale development, driving the demand for perfluorinated ion exchange membrane applications to rise. . Due to technical limitations, the output of perfluorinated ion exchange membranes in my country is low, and overseas brands dominate the Chinese market. However, with the support of national policies, the continued efforts of local enterprises in my country will drive the localization rate of perfluorinated ion exchange membranes to continue to increase.

微信扫一扫打赏

微信扫一扫打赏