The market demand for molecular sieves continues to increase, and the industry has broad prospects for development

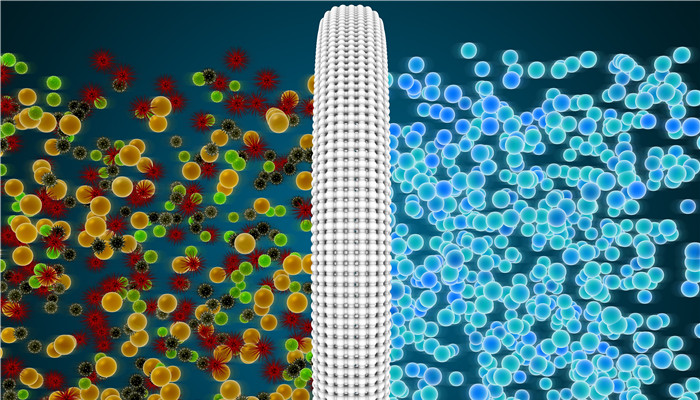

Molecular sieve, also known as zeolite, is a type of inorganic crystal material with regular and uniform pore structure. According to different pore structures, molecular sieves can be divided into microporous molecular sieves, mesoporous molecular sieves, macroporous molecular sieves, and composite pore molecular sieves; according to different sources, they can be divided into natural molecular sieves and synthetic molecular sieves. Molecular sieves have the characteristics of high specific surface area, large surface acidity, good thermal stability, and strong ability to screen molecules. Therefore, they have high catalytic, adsorption, and separation functions. They are widely used in petrochemical industry, coal chemical industry, fine chemicals, nuclear wastewater treatment, and saline-alkali land management. It is widely used in other fields.

In recent years, with the continuous strengthening of domestic environmental protection efforts and the continuous advancement of dual-carbon goals, the market demand for molecular sieves has continued to increase. At present, my country has become one of the largest consumers of molecular sieves in the world. According to the “2022 Molecular Sieve Industry Investment Feasibility Analysis Report” released by the Industrial Research Center It shows that the domestic molecular sieve market consumption in 2021 is about 108,000 tons, and my country’s consumption accounts for 30% of the global total consumption. In addition to China, North America and European countries are also regions with high global consumption of molecular sieves.

From the perspective of the global market, European and American companies currently occupy a leading position in the market. In 2021, the three major companies, Honeywell, Arkema, and Zeochem, occupy the main share of the global market, accounting for a total of 45% of the market share. my country’s molecular sieve industry started late, but after development in recent years, as domestic companies continue to break through key technologies and optimize product performance, local leading companies Jianlong Micronano, Shanghai Hengye, Dalian Haixin, and Qilu Huaxin continue to occupy More market share, currently four local companies occupy a total of 15% share.

According to different product forms, molecular sieves can be divided into molecular sieve activated powder and shaped molecular sieves. Molded molecular sieve is an inorganic non-metallic material made from molecular sieve raw powder and binder in a certain proportion. Molded molecular sieve technology and financial barriers are high. Currently, local companies are mainly concentrated in the mid- to low-end market, while the high-end molded molecular sieve market is still dominated by foreign companies. In the future, local companies will need to continue to improve relevant technical levels and increase investment in research and development, thereby increasing the production of high-end molded molecular sieves and promoting companies to occupy more high-end market shares.

Industrial analysts said that molecular sieves are currently widely used in scenarios such as automobile exhaust treatment, medical oxygen generators, recovery and purification of hydrogen, etc. , in recent years, against the background of the continuous development of its application fields, the market demand for molecular sieves has continued to increase, and the industry development prospects are good. In the future, under the background of the continuous advancement of domestic dual-carbon goals and the continuous strengthening of environmental protection policies, the molecular sieve industry still has huge room for development. Driven by broad development prospects, local companies will continue to increase investment in research and development in the future to promote continuous improvement of product quality and performance, thereby accelerating the continuous improvement of localization levels.

微信扫一扫打赏

微信扫一扫打赏