In order to meet the goals of green manufacturing and carbon reduction, Eternal Materials has launched a thin-type UV light-curing protective tape resin, which can be cured with aerobic and anaerobic UV light.

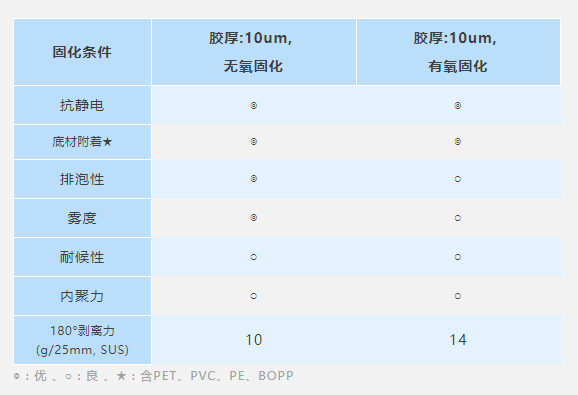

This protective glue material can adjust the glue formula and characteristics according to the needs of customers, so that it can show its excellent protective performance. At the same time, it has excellent cohesion. When the tape is removed, there will be no residual glue on the surface of the adherend. It has an antistatic effect, so that when the protective film is torn off, no static electricity will be generated and the sample will be injured. Low adhesion (low)

adhesion), heavy work becomes easy without worrying about polluting the surface of the adherend, excellent defoaming performance, convenient for quick manual lamination, and good scratch resistance to reduce product damage during the production process or transportation process.

It can be widely used in household dustproof, glass cutting dustproof protection, surface protection of stainless steel, aluminum, decorative metal plates, other metal products and circuit substrates, casing products, curing materials used in the automotive industry, and optoelectronic materials, etc. Protective glue. In addition, this product has excellent adhesion to PET, PVC, and BOPP.

UV light curing protective tape resin is based on polyurethane acrylate material for UV light curing protective adhesive.

1. Low shrinkage, good cohesion and low adhesion;

2. Applicable UV curing energy: 1,000~1,200mJ/cm2

3. It can be operated at a room temperature of 18~25°C and a humidity of 50~70%.

Application of stainless steel protective glue

Application of circuit board protective glue

微信扫一扫打赏

微信扫一扫打赏