Diborane is mainly used in the semiconductor industry. The number of manufacturing companies in my country is small.

Diborane, with the chemical formula B2H6, is an inorganic compound and is the simplest borane that can be isolated at present. It appears as a colorless gas at room temperature, has a special odor, is highly toxic, is easily hydrolyzed, and is easily soluble in carbon disulfide. Diborane is explosive in moist air, decomposes at room temperature, and can react violently with a variety of organic solvents and metals. Therefore, diborane has strict storage conditions and needs to be stored in a low-temperature, dry environment, away from heat sources and open flames. As well as oxidants, halogens and other substances.

Industrially, diborane is usually prepared under vacuum conditions, using sodium hydride and boron trifluoride as raw materials, reacting in an organic solvent to obtain a crude product, and then undergoing condensation purification and other processes to obtain a high-purity product. The by-product is sodium fluoride. . Other preparation methods of diborane include: using sodium borohydride and sulfuric acid as raw materials; using potassium tetrahydroborate and phosphoric acid as raw materials; etc.

Diborane can be used as a doping source in the semiconductor industry; as a high-energy fuel in rocket and missile manufacturing; as an organic synthesis raw material in the chemical industry; and in the preparation of high-purity boron single crystals; It can also be used in pharmaceutical, metal welding and other fields. Among them, the semiconductor industry is an important downstream market for diborane.

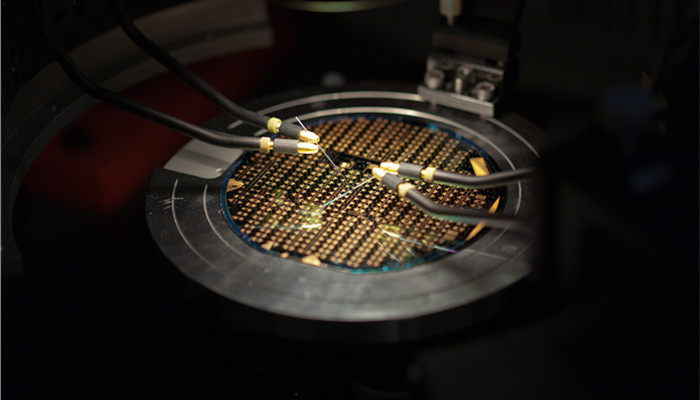

According to the “In-depth Market Research and Investment Strategy Suggestions Report on Diborane Industry 2021-2025” released by the Industrial Research Center, silicon Wafer processing requires the use of electronic special gases and wet electronic chemicals for cleaning, photolithography, etching, epitaxy, doping and other processes. Doping refers to the introduction of specific elements to enhance the electrical properties of the silicon wafer. It can use ion implantation, oxidation Diffusion method, boron doping is one of the main doping processes. It is doped with diborane, trifluoroethylboron and other elements into silicon wafers, and is mainly used to manufacture P-type semiconductors. In addition to doping, diborane can also be used in the epitaxial growth of silicon and germanium.

In the global market, Voltaix of the United States is the electronic-grade diborane manufacturer with the highest technical level and the largest production scale. It was acquired by the French Air Liquide Group in 2013. Diborane has poor stability and is difficult to transport over long distances. Against the background of the continuous expansion of the scale of my country’s semiconductor industry, there is an urgent need for independent production of diborane in my country. Baoding North Special Gas Co., Ltd. is the first company in my country to achieve mass production of high-purity diborane. Diborane manufacturers in my country include Taihe Gas (Jingzhou) Co., Ltd.

Industry analysts said that in addition to domestic companies, foreign gas manufacturers are also building diborane plants in China due to market prospects. . In 2017, Japan’s Taiyo Nippon Sanso built a new special gas factory in Yangzhou, Jiangsu, to produce diborane, a gas used in semiconductor manufacturing. The scale of my country’s diborane industry is constantly expanding, but the number of companies capable of mass production is still small. Due to its toxicity, poor stability, and high risk factor, diborane production requires high technology and qualifications for companies, and they do not have certain strength. It is difficult for enterprises to enter the layout.

微信扫一扫打赏

微信扫一扫打赏