On February 23, the FAW-Volkswagen Supplier Partner Conference “Core Resource Strategy-Raw Materials” theme forum was successfully held in Changchun. Dr. Wang Shaojie from Wanhua Chemical was invited to attend the meeting and give a keynote speech.

In recent years, FAW-Volkswagen has continuously accelerated the transformation of “low-carbonization, digitalization, and intelligence”. With the goal of “full-life cycle carbon emission reduction”, it has promoted green development in terms of products, production, and upstream and downstream industries. This is also a challenge for raw material suppliers. Putting forward higher requirements, Wanhua Chemical, relying on its outstanding upstream and downstream integration advantages, puts forward the overall automotive material solutions around the multiple needs of the automotive industry for performance improvement, carbon reduction, and recycling, and continues to help the automotive industry move towards electrification, Lightweight, intelligent, high perception, health and environmental protection, low-carbon energy saving and other directions.

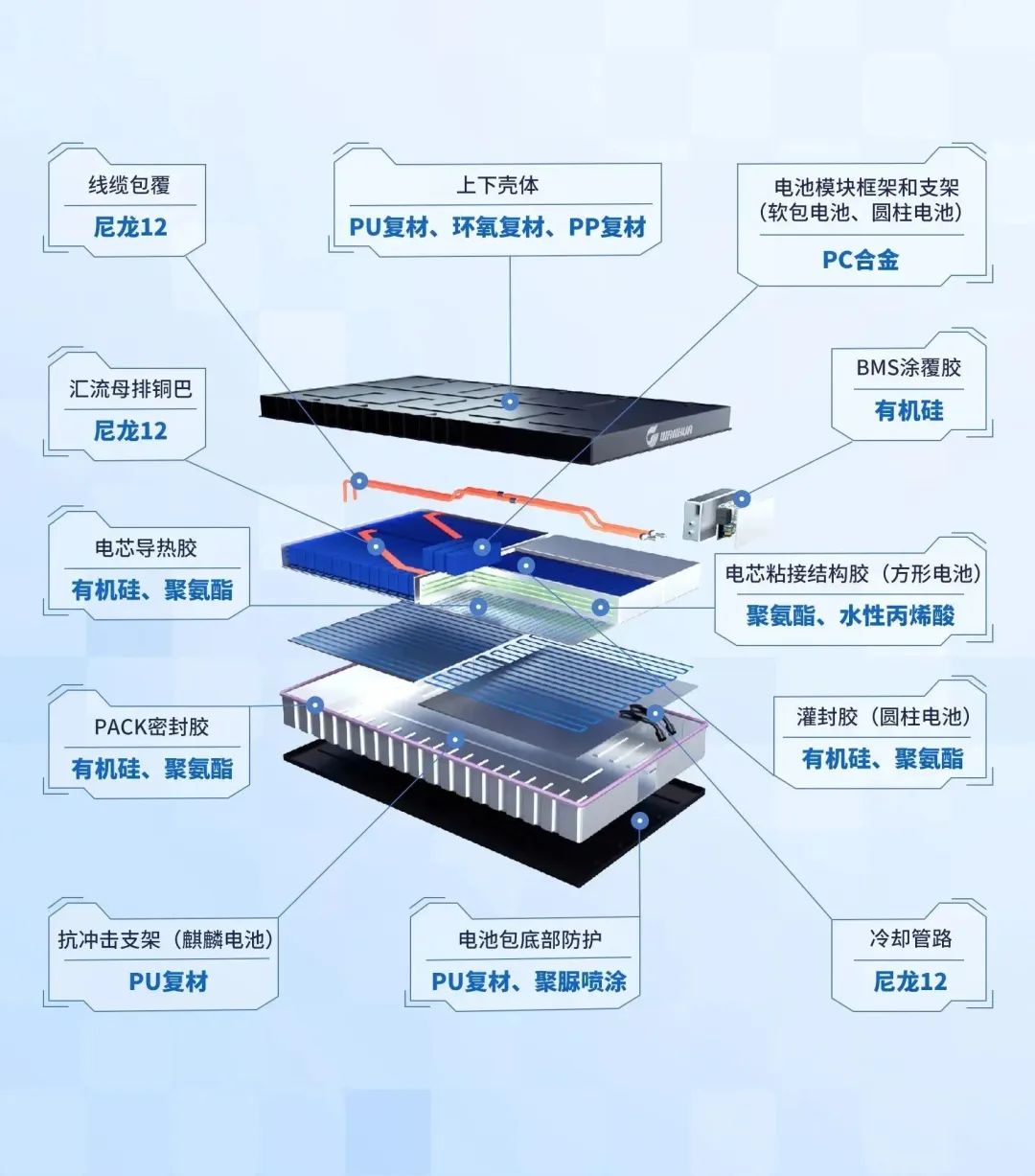

Battery pack system solution provides perfect battery life for your car

As the “heart” of new energy vehicles, batteries hold the lifeblood of the development of new energy vehicles to a certain extent. For new energy vehicles, the flame retardancy, thermal conductivity, sealing, and impact resistance of raw materials are directly related to the cruising range and driving safety of the vehicle.

Through the innovation and upgrading of various materials such as polyurethane, modified plastics, composite materials, and silicones, Wanhua Chemical has brought overall material solutions for battery packs to the industry. In the future, Wanhua Chemical will also give full play to the advantages of the chemical industry cluster, and jointly build a circular ecological industrial chain with downstream customers to help the sustainable development of the industry.

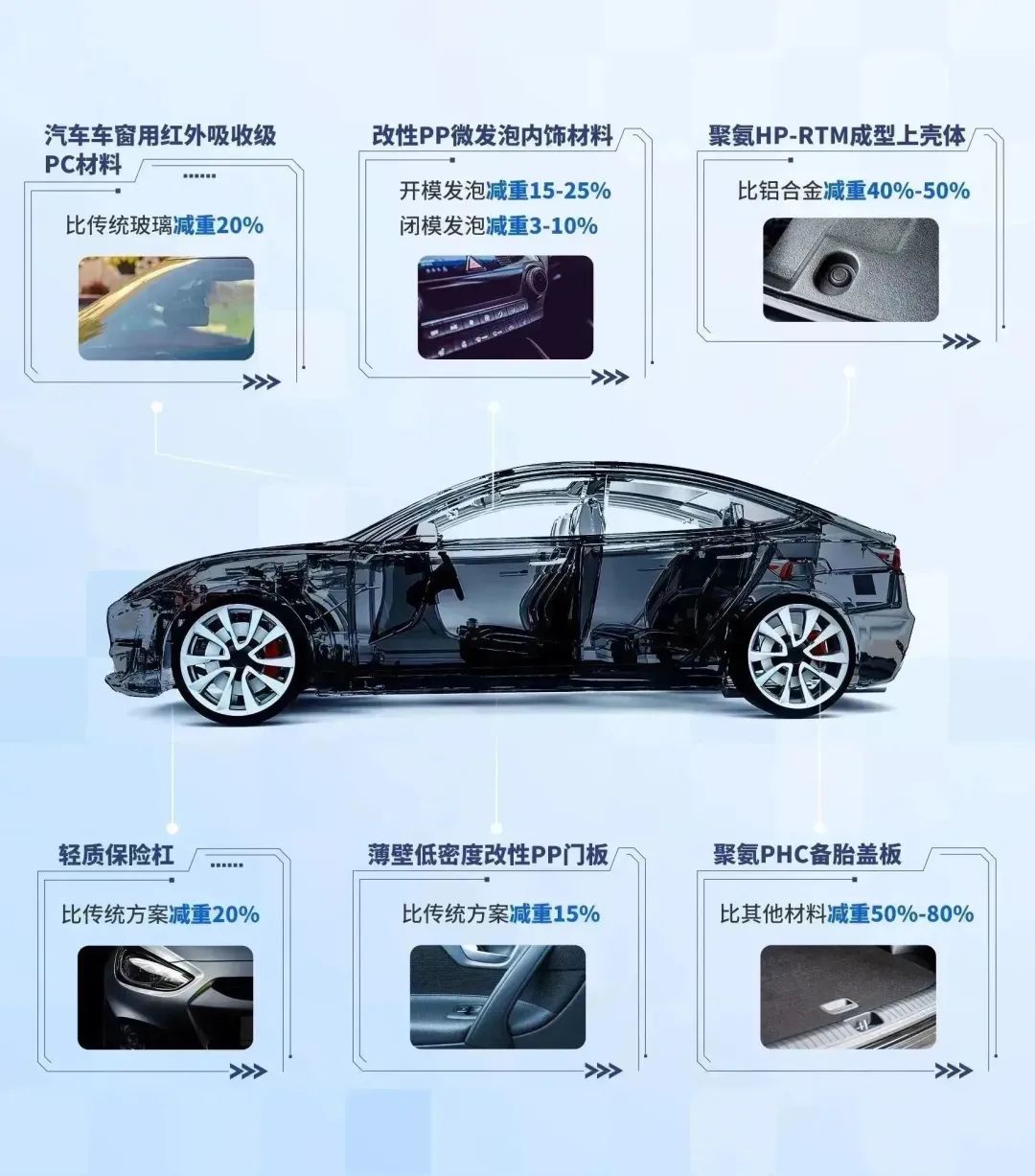

Lightweight solutions help achieve lower energy consumption

In order to ensure the realization of long cruising range, the weight reduction of electric vehicles becomes more important. In the direction of lightweight, such as modified PP micro-foamed interior materials, thin-walled low-density modified PP door panels, infrared-absorbing PC materials for automotive windows, polyurethane HP-RTM formed battery pack upper shells, lightweight bumpers , The use of polyurethane PHC spare tire cover can reduce the weight of parts by 20%-50% on average, effectively improving the weight reduction.

Intelligent solutions to meet diversified consumer needs

In terms of car intelligence, Wanhua Chemical meets the more diversified and personalized needs of consumers through material innovation.

High-flow light-guiding transparent PC material has high light transmittance, good fluidity, good long-term thermal stability, and meets the requirements of white light transmittance to make the smart cockpit more technologically aesthetic; low dielectric loss PP material has low dielectric constant, low The characteristics of dielectric loss, high dielectric strength and high signal transmission can realize the integrated application of millimeter wave radar and bumper. In addition, infrared-transmitting PC materials can be used in infrared sensors to protect the car’s intelligent perception.

In the future, Wanhua Chemical will continue to use green innovative materials as the engine, give full play to the advantages of the integration of the upstream and downstream industrial chains of the four major business segments of polyurethane, petrochemicals, fine chemicals, and emerging materials, and join hands with more partners to improve the efficiency of the automotive industry Contribute to cost reduction, green transformation, and high-quality development.

微信扫一扫打赏

微信扫一扫打赏