BASF, Flex-N-Gate, Toyota and L&L Products nominated for 2023 JEC Innovation Award in Automotive & Road Transport – Design Section for Composite Seat Back Design on 2022 Toyota Tundra™ finalists. Previously, the project was awarded the 2022 Altair for its achievements in weight reduction

Enlighten Award and 2022 SPE Automotive Innovation Award.

Vik, Manager, Engineering Chassis Group, Toyota Corporation

Bhatia said: “Pultrusion composite technology allowed us to design a seat structure that is 20% lighter than previous models and meet our cost targets. BASF, L&L Products and Flex-N-Gate are great partners. Helped us achieve our goals.”

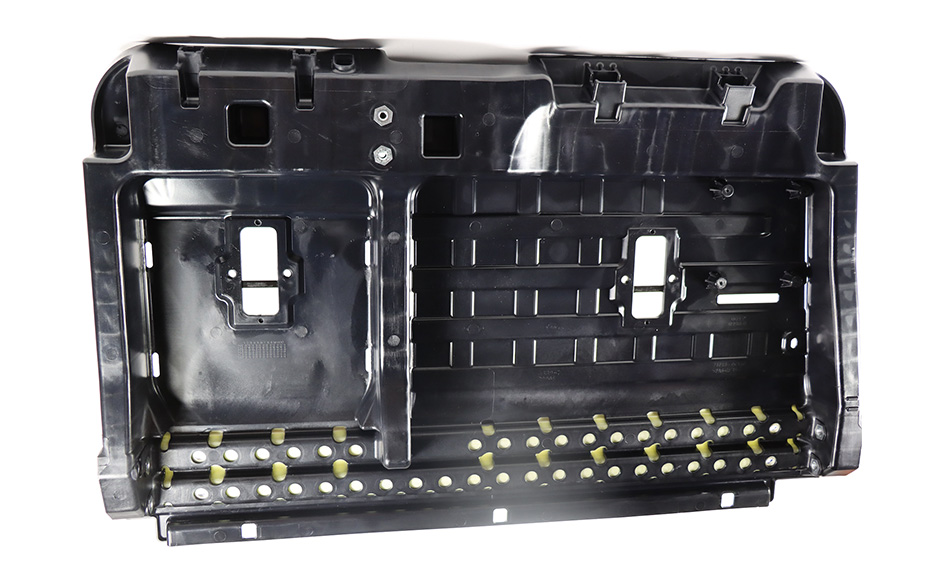

The seat structure is the first automotive interior application of L&L Products’ Continuous Composite System™ (CCS™) technology, which uses BASF’s polyurethane pultrusion system Elastocoat®

74850. CCS is a fiber-reinforced composite carrier with a 2D profile of highly engineered sealants and adhesives. In this application, it is combined with BASF’s impact-modified polyamide 6 Ultramid®

The B3ZG7 CR are stacked together to form the three-dimensional shape of 60% of the seat back.

Hank, Product Engineering Manager, L&L Product Department

“Through this partnership, we were able to eliminate an all-steel assembly consisting of 60 stamped and welded parts and consolidate these parts into four composite parts, reducing assembly and scrap costs associated with metal seat structures,” said Richardson .It also makes the seating system more functional.”

Kipp, Head of Thermoplastic Composites Technology, Performance Materials Division, BASF

“We will continue to demonstrate how pultrusion technology can provide lightweight, economical solutions with integrated functionality,” Grumm said. The unique design of the injection-molded pultruded beams in the seat structure also passed all relevant crash test requirements, Opens the door for greater adoption of composites in automotive applications.”

微信扫一扫打赏

微信扫一扫打赏