A few days ago, Momentive Group released a new product of hardening coating – SilFORT®

UVHC8100, hardened coating for ultra-high solids automotive lamps. Momentive has always been adhering to the promise of a better future for human beings and the environment. As early as 2013, it has started research on ultra-high solid UV coatings. Now SilFORT

UVHC8100 has completed 3 years of natural exposure experiments, and also completed the ECE approval with mainstream polycarbonate substrates, which can be directly applied to the automotive lighting industry.

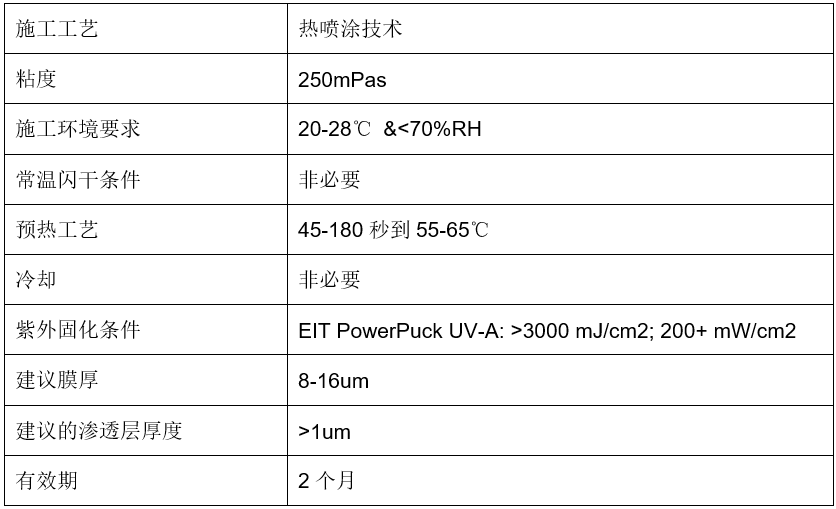

UVHC8100 Physical Properties Table

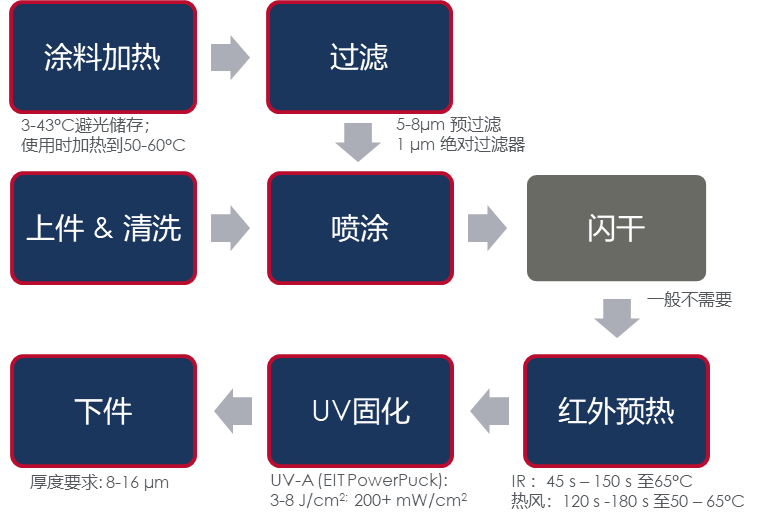

UVHC8100 thermal spraying process flow chart

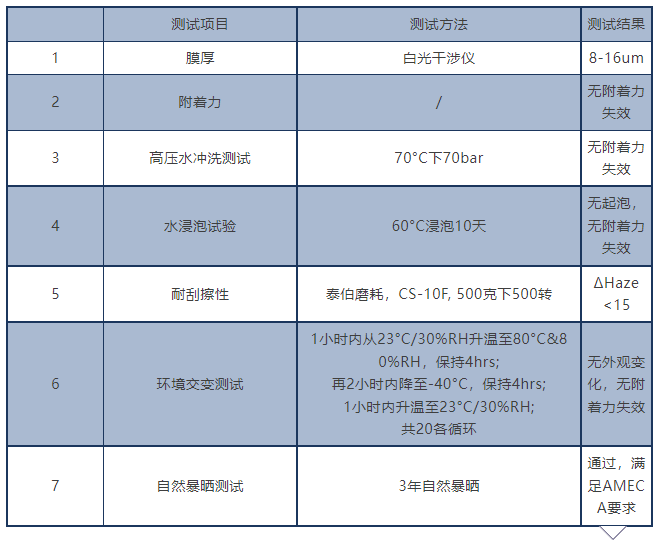

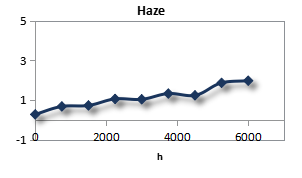

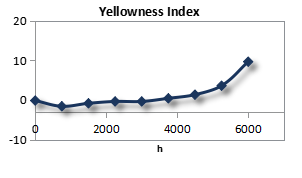

Performance metrics

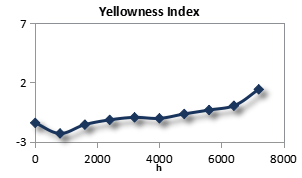

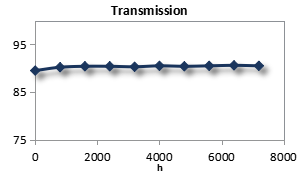

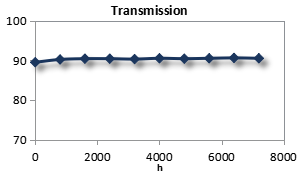

Xenon lamp aging test results1. Simulated hot and humid climate environment

2. Simulate dry climate environment

SilFORT* hard coatings enable automakers to replace glass and metal with lightweight plastics in demanding applications including lighting, glazing, exterior,

Sensor cover, in-vehicle and new front-end module applications. It can improve polycarbonate and poly

The durability and performance of plastics such as methyl methacrylate helps them retain color, gloss, light transmission and other physical properties while enhancing their resistance to weathering, easy cleaning, abrasion, chemicals and solvents.

SilFORT hard coatings enable innovative applications of plastic materials in a variety of industries. In the field of transportation, plastics protected by hardened coatings can be used in automotive lighting, glass, exterior trim, interior parts and new front module applications. Many applications paved the way.

Momentive Hard Coating Division provides a wide range of surface treatment solutions for automotive parts, including: PC substrates, PMMA substrates, PC/ABS alloys, PET substrates, aluminum and anodes

Alumina products, etc. It can be widely used in car lights, car windows, front and rear grille covers, pillar covers and other products, and there are a large number of mass production cases.

微信扫一扫打赏

微信扫一扫打赏