From medical devices to mobile devices and more, printable electronics have transformed the form and function of products across multiple industries. Substrates play a pivotal role in driving the functionality and applications of printable electronics, and Covestro is a leading company in this field, providing highly engineered polymer and substrate solutions for products that contribute to smarter living plan. Covestro collaborates and innovates together with manufacturers to produce specialty films, especially polycarbonate (PC) and thermoplastic polyurethane (TPU) for the manufacture of printed electronics.

At LOPEC 2023 in Munich, Germany, from February 28 to March 2, Covestro will present special films for printed electronics.

Karine, Global Head of Medical Division, Specialty Films Business, Covestro

“We are delighted to be exhibiting at LOPEC for the first time, recognized as one of the world’s premier gathering places for exchanging ideas and introducing printed electronics technology,” said Benbelaid. “We will be highlighting our custom PC, TPU and specialty elastomer films, we look forward to demonstrating our technical expertise and ability to drive industrial collaboration.”

Novel TPU films and applications for smart skin patches

Covestro to debut its new Platilon® for smart skin patches at LOPEC 2023

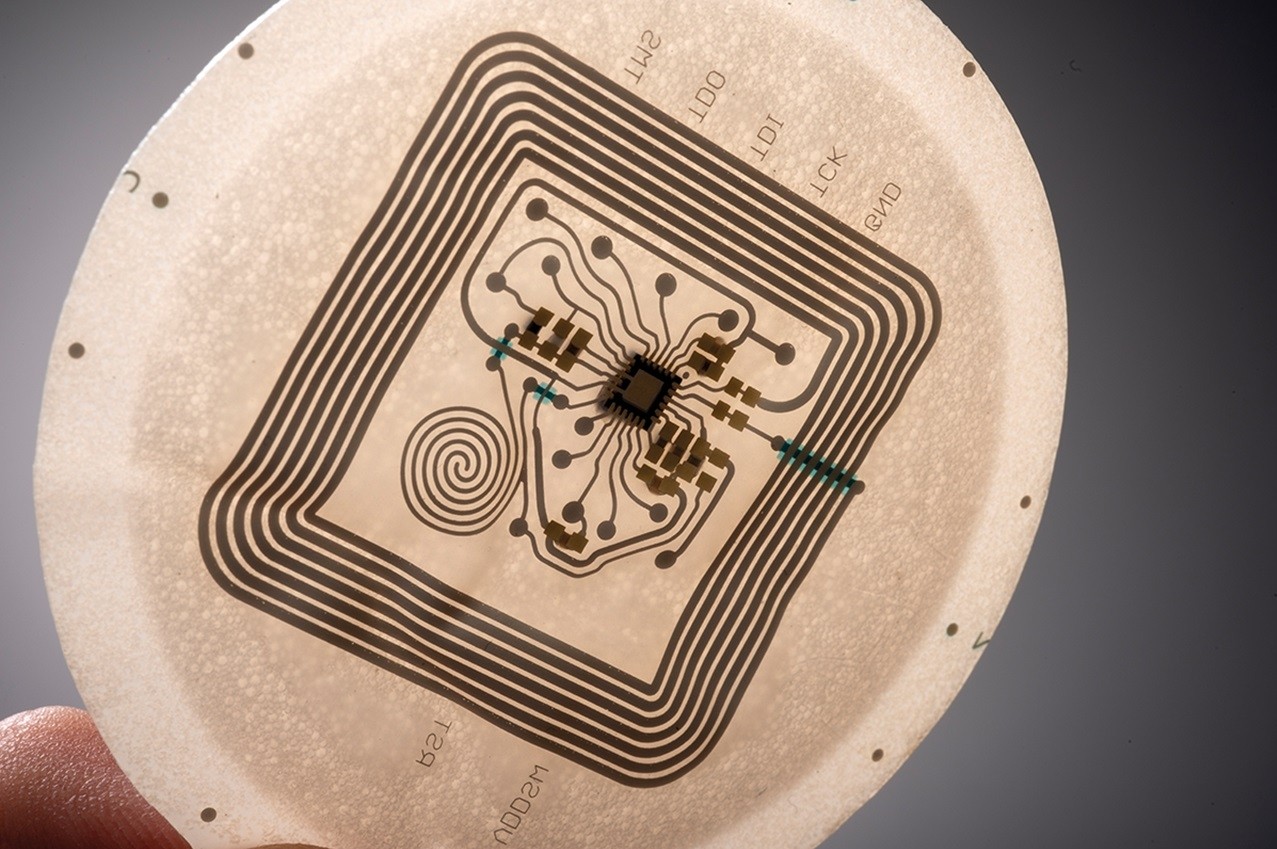

TPU products. The new series of TPU films can not only be printed with standard inks, but also show good printability in silver-based inks. The printability of silver-based inks is important because it ensures good electrical conductivity and enables more reliable integration of sensor technologies. In addition, the new TPU film grades can be equipped with a stiffer polypropylene carrier, which provides stability throughout the conversion process, especially during curing.

One of the new Platilon®

TPU grades are designed for wet environments and are typically used in medical patches that need to be worn 24/7. Some of this range of medical-quality substrates are available in bio-based versions. Another New Platilon®

The TPU series has high mechanical strength, and it is being used in various equipment. Nile AB chose this new material to produce wearable sensor patches.

Nile AB CEO Peter

“The future of printed wearables belongs to groundbreaking patches that improve patient comfort and accuracy,” said Nilson. “We chose to use Covestro’s new TPU substrate because it has been perfectly adapted to our unique conversion process.” and printing of silver-based flexible circuits.”

Visitors at the booth can also see the smart skin patch jointly developed with Acensors, which has two types: one is a disposable patch with sensors inside and can only be used once; the other is multiple times Use a patch, which contains electronics and can be reused.

Smart Material Solutions for Automotive and Electronics

Covestro will also highlight key human-machine interface (HMI) applications of in-mold electronics (IME) in automotive and electrical design, including:

● Front-end concepts for future-oriented integrated cars to create high-level and basic model designs

● Smart 3D plastic surfaces using Injection Molded Structural Electronics (IMSE®) technology from TactoTek® with Makrofol® PC film and Makrolon® PC

resin bonded

● A full-featured, stylish car roof panel sample

● Smart surface controller devices that meet future design, sustainability and technology requirements

微信扫一扫打赏

微信扫一扫打赏