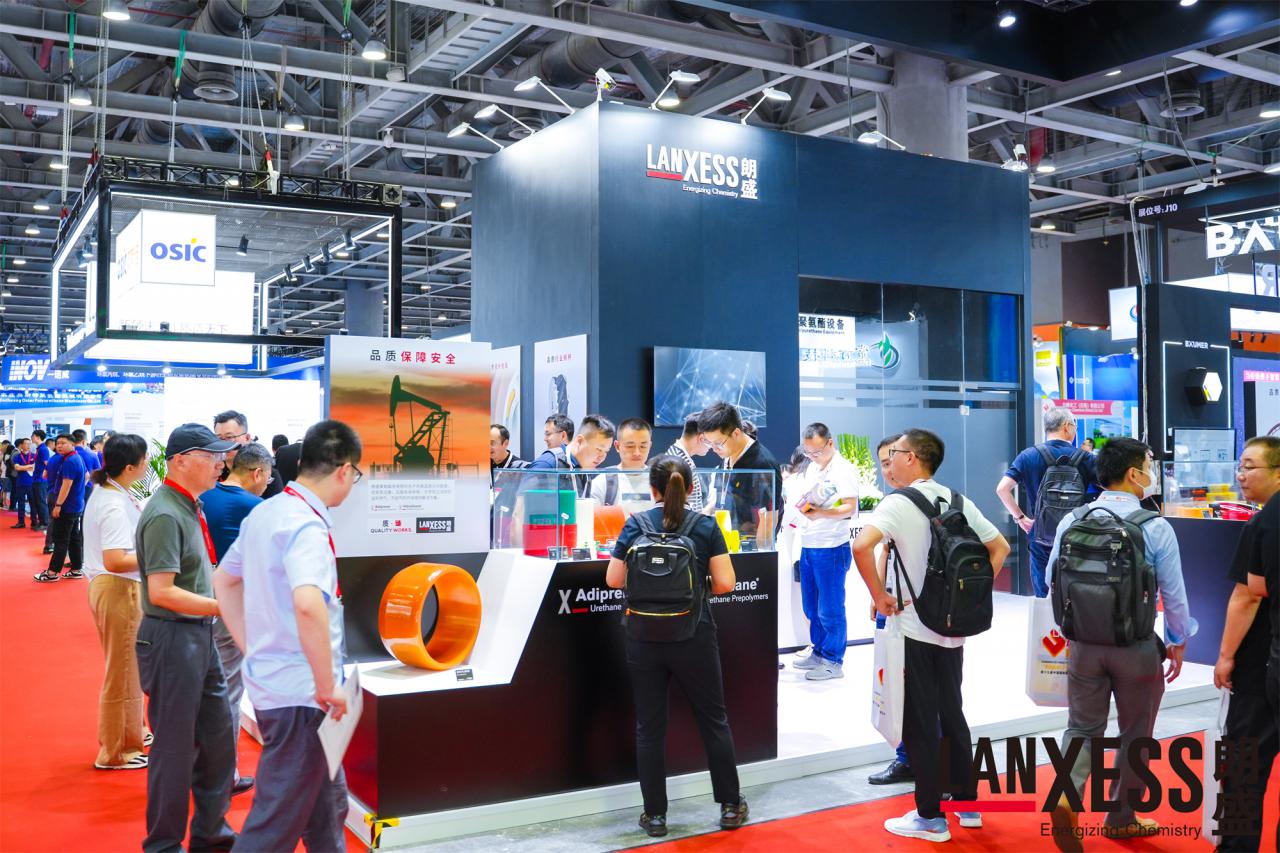

Specialty Chemicals Company LANXESS participated in the 19th China International Polyurethane Exhibition in Guangzhou from August 2 to 4 exhibition (PUChina2023), and showcased a series of innovative products and solutions related to carbon neutrality.

“Carbon neutrality has become a global topic, and the carbon reduction actions of Chinese companies are also constantly advancing. In this process, technological innovation is the key. LANXESS is committed to solving solutions, provide support to customers who are increasingly looking for sustainable solutions, and help improve the sustainability of the entire value chain.” Zhang Zhenglei, Vice President of Asia Pacific of Lanxess Polyurethane Systems Business Unit, said.

Bio-based products help reduce carbon emissions

At this exhibition, LANXESS demonstrated the newly developed AdipreneGreen brand MDI polyether polyurethane prepolymer, which uses renewable bio-based raw materials and can help polyurethane processors reduce 20% to 30% % of CO2 emissions (depending on the specific polyurethane system). Compared with traditional petroleum-based polyether prepolymers, the AdipreneGreen series is based on different target hardness of polyurethane elastomers, and the proportion of bio-based raw materials can be as high as 30% to 90%. At the same time, the existing polyurethane processing equipment will continue to be applicable, and its processing method is basically the same as that of traditional prepolymers, without the need to adjust material handling methods, processing temperatures or even mixing ratios. AdipreneGreen prepolymer can also flexibly choose manual mixing or machine mixing pouring processing methods according to site conditions.

LANXESS AdipreneGreen uses starch-based polyether polyol raw materials, and the comprehensive performance of the final polyurethane elastomer will be at the same level as the existing mature petroleum-based polyether-based elastomers, or even better. By reacting AdipreneGreen prepolymer with 1,4-butanediol, a series of high-performance polyurethane elastomers with hardness ranging from 40ShoreA to 60ShoreD can be obtained. At the same time, AdipreneGreen prepolymer can also be used in conjunction with Lanxess’ Vibracat catalyst. The AdipreneGreen series of products are ideal for applications that require demanding elastomer properties, such as rubber roller lagging, industrial rollers, paper machine boot covers, and non-inflatable tires.

Furthermore, LANXESS presented a hot casting and cold curing system for polyurethane cast elastomers. Through this new technology, Vibrathane’s new prepolymers can be cured at room temperature with the new Vibracure curing agent, thereby improving ease of use, promoting energy conservation, and improving environmental health and safety. Depending on the setup of the polyurethane plant, total energy consumption can be reduced by up to 40%-50% using this system.

Focus on green energy applications

While promoting the transformation of its product portfolio to climate neutrality, LANXESS is also committed to working closely with downstream application fields to build a sustainable innovation ecosystem. In August last year, LANXESS announced its scope 3 emission targets, and plans to achieve climate neutrality in the upstream and downstream supply chains by 2050. To achieve this goal, LANXESS has launched the “Net Zero Value Chain Plan” to take the next step together with suppliers and customers through sustainable raw materials, green logistics and climate-neutral products.

Among them, the application of new energy industry is the key point of Lanxess Polyurethane Systems Business Department.The focus of ��. Statistics show that more than 80% of global carbon emissions come from energy production and consumption. According to the statistics of the International Energy Agency (IEA), China’s total carbon emissions in 2019 were 11.3 billion tons, and the carbon emissions in the energy sector were 9.8 billion tons, accounting for 87% of the national total. To complete the low-carbon transformation of energy, technological innovation is the only way.

Relying on polyurethane system expertise, global production capacity, profound application development experience and decades of technology accumulation, LANXESS polyurethane can provide an important guarantee for the development of clean energy such as solar energy, wind energy, and nuclear energy . In order to meet the needs of offshore wind power generation, the cable protection tube cast by LANXESS polyurethane system has significant anti-wear, tear-proof, anti-lysis and corrosion-resistant functions, which greatly prolongs the service life of cables and helps to deal with safety and environmental protection in green energy applications challenge. Lanxess polyurethane products are widely used in the photovoltaic industry, from silicon ingot cutting, squaring, slicing, to subsequent silicon wafer processing, with its excellent wear resistance, temperature resistance, and chemical substance stability, it helps the sustainable development of the photovoltaic industry.

LANXESS provides photovoltaic cutting rollers with stable performance, which are extremely important components in photovoltaic power generation. They have excellent wear resistance, scratch resistance, toughness and high load performance, and can adapt to harsh environments . The coating sprayed by the low-free polyurethane prepolymer provided by LANXESS has the characteristics of high strength, high wear resistance, corrosion resistance, high bonding strength, high temperature resistance, etc. The reactor is woven with a strong shield, which can protect the heavy water reactor for more than 20 years.

Diverse and customized application scenarios

LANXESS also presented a broad product portfolio, from the innovative AdipreneGreen brand prepolymers with low free (LF) monomer technology and high biobased content to the new thermocasting with lower processing energy consumption and cold curing systems, as well as waterborne coatings for the high requirements of modern automotive interiors, the product range is extremely extensive.

LANXESS Polyurethane Systems is one of the world’s leading suppliers of polyurethane systems for elastomers, coatings, adhesives and sealants. With polyurethane system expertise, global production capabilities, deep application development experience and decades of technology accumulation, the division is able to provide industrial, mining, transportation, electronics, energy, tires, construction, paper, consumer goods and even healthcare industries. Customers in other fields provide specially developed custom solutions.

微信扫一扫打赏

微信扫一扫打赏