Covestro launches Makrolon Rx3440, a material resistant to tumors Solvents in treatments and cleaners. The durability and chemical resistance of this medical polycarbonate product helps prevent cracking, making it safer for medical professionals to administer drugs to cancer patients.

According to Lauren Zetts, Marketing Manager for North America Medical and Consumer Goods – Polyurethane at Covestro (Leverkusen, Germany), cancer treatment is difficult to perform using plastics. Strong solvents used in oncology treatments, such as benzyl alcohol and dimethylacetamide, can cause IV (intravenous drip) connectors to crack, she said. The FDA (Food and Drug Administration) and the Institute for Safe Medication Practices issued a warning in 2015 reminding healthcare practitioners to avoid the use of closed-system polycarbonate delivery devices due to the possible risk of leakage or breakage.

Another challenge is that the connectors need to be seated tightly for a long time during use to prevent leakage. Polycarbonate is often chosen because it is less prone to loosening over time, or temperature rise due to stress relaxation.

Makrolon Rx3440 product was developed to meet the high demands of IV connectors, its biocompatibility and toughness can avoid mishandling, and the material can also be used in thin wall applications.

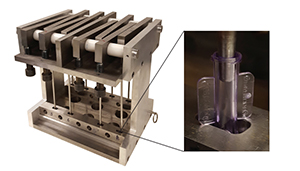

To test chemical resistance and stress relaxation resistance, Covestro has developed a new device that focuses on immersion under actual loading conditions. The device is designed to be adjustable in force for accelerated testing. Covestro customers are also invited to test existing Luer connectors on-device, Zetts said. The test is comprehensive and meets the more serious realities of cancer treatment, she said.

With the new device, Covestro demonstrated that its Makrolon Rx3440 polycarbonate product has better chemical and tumor resistance than other transparent resins used to manufacture IV connector parts. also. The material also exhibits optimum stress retention for more reliable IV connections.

微信扫一扫打赏

微信扫一扫打赏