Spandex scientific name polyurethane fiber, also known as polyurethane Elastic fibers, which belong to the category of synthetic fibers, are highly elastic and can be stretched6~7 times, but can quickly return to the original state with the disappearance of the tension, its molecular structure is a chain-like, soft and extensible polyurethane, through the combination with the hard chain Segments are linked together to enhance their properties. Spandex has excellent performance, and spandex is known as ” MSG type”Fiber, adding a small amount can significantly improve the elasticity and comfort of chemical fiber products, and its price is much higher than other types of synthetic fibers.

There are four main production process routes of spandex: dry method Spinning, melt spinning, wet spinning and chemical reaction methods. Dry spinning technology is the most mature, and it is the most widely used spinning method in the world at present. The output of spandex produced by this method accounts for the total output of spandex in the world86%.

Table1 Comparison of different production process routes of spandex

|

Production Craft |

Dry Spinning |

melted spinning |

wet Spinning |

Chemistry Reaction method |

|

Method Introduction |

The solution is under hot air , solidified into silk due to solvent volatilization |

2-510,000 tons |

2021-2023year |

|

|

Total |

71-7410,000 tons |

Data source: company announcement

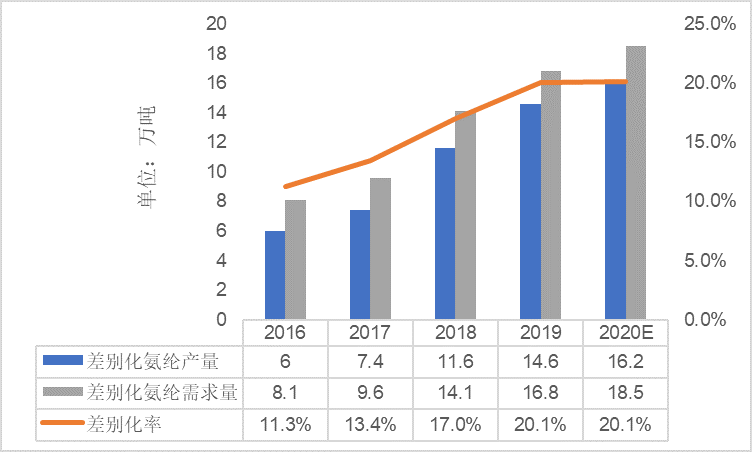

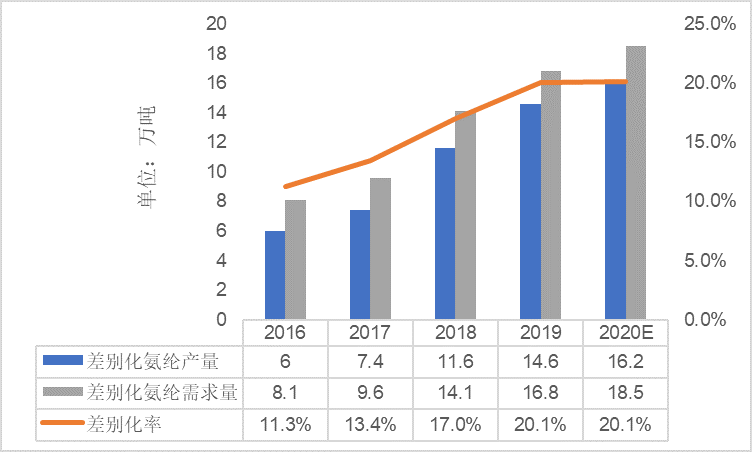

Differential spandex has broad growth potential in the future

Differential spandex is made by adding specific functional substances, The whole polyurethane soft, hard segment structure and aggregate structure can improve the performance of spandex. Compared with ordinary spandex, differentiated spandex has significant performance advantages, including high-temperature resistant spandex, chlorine-resistant spandex, low-temperature setting spandex, dyeable spandex, deodorant spandex, degradable spandex, and anti-slip spandex, etc. Differential spandex has a wide range of downstream applications, and can be used in high-end underwear, swimwear, suit fabrics and medical fields.

2016-2019The proportion of differentiated spandex continues to increase,19Annual proportion 20.1%. 2020Yearly Differentiation Rate20.1%Conservative estimate ,2020The annual differentiated spandex output is16.2million tons, the demand is18.5 tons. Differentiated spandex is the main development trend in the future, and there is a huge room for future growth. At present, leading enterprises in the industry have begun to lay out differentiated spandex, among which Huafeng Chemical will build3010,000 tons of differentiated spandex project, total project investment43.6100 million yuan, estimated construction period6Year,1-3Period construction510,000,15Ten thousand and1010,000 tons of differentiated spandex. Shandong Ruyi Group is also investing in Yinchuan Binhe New Area1210,000 tons of differentiated spandex fiber project.

Figure 4 2016-2020China’s differentiated spandex production, demand and differentiation rate

Data source: China Chemical Fiber Industry Association, Zhi Research Consulting, Tiantian Chemical Network

Project, total project investment43.6 100 million yuan, estimated construction period6年,1-3Period construction5Ten thousand tons,15 Ten thousand and10Ten thousand tons of differentiated spandex. Shandong Ruyi Group is also investing in Yinchuan Binhe New Area1210,000 tons of differentiated spandex fiber project.

Figure 4 2016-2020China’s differentiated spandex production, demand and differentiation rate

Data source: China Chemical Fiber Industry Association, Zhi Research Consulting, Tiantian Chemical Network

微信扫一扫打赏

微信扫一扫打赏